We have a large warehouse to stock all the sizes of stainless steel seamless tube, our factory certificated by ISO9001 and also TUV, DNV, ABS, BV, LR qualified, always get warm praise from our customers all over the world, we are your provider of stainless steel seamless tubing.

Excellent stainless steel seamless tube is an essential component in various industrial applications. These tubes are made of high quality stainless steel for excellent corrosion resistance, strength, and durability.

Material

high performance stainless steel seamless tube is made from a combination of iron and chromium. The chromium in the material provides corrosion and stain resistance, making it ideal for use in harsh environments. These tubes can also contain nickel, molybdenum, titanium, and other elements to enhance their performance. The most common types of stainless steel used for seamless tubing are 304 and 316.

Nickel is commonly added to stainless steel tubing to enhance its resistance to both corrosion and high-temperature environments. This addition improves the overall strength and toughness of the tubing, making it highly suitable for applications that require excellent mechanical properties and resistance to extreme conditions.

Molybdenum is another essential element often found in high-performance stainless steel tubing. It offers enhanced resistance to pitting and crevice corrosion, making the tubing highly reliable and durable in corrosive environments such as marine or chemical processing applications.

Titanium, on the other hand, contributes to the tubing’s exceptional strength-to-weight ratio, making it a preferred choice for applications that require lightweight materials without compromising on structural integrity.

The two most commonly used types of stainless steel for seamless tubing are 304 and 316. Type 304 stainless steel is known for its excellent corrosion resistance and is widely used in various industries such as food processing, pharmaceuticals, and architecture. It offers good resistance to most chemicals, as well as atmospheric and fresh water environments.

Type 316 stainless steel, on the other hand, provides superior corrosion resistance compared to 304. It contains higher levels of molybdenum, which enhances its resistance to chloride-induced corrosion. This makes it highly suitable for applications exposed to harsh chemicals, saltwater environments, and marine applications.

characteristic

Has many advantages. Their high strength and durability make them ideal for high pressure applications. They are also resistant to corrosion, stains, and rust, making them ideal for use in harsh environments. In addition, their heat resistance and smooth surface make them ideal for hygienically demanding applications.

Advantage

As a high-quality pipe material, high-performance stainless steel seamless tube has many advantages, making it widely used in various fields. The following is a detailed description of its main advantages:

1. Corrosion resistance: High-performance stainless steel seamless tube has excellent corrosion resistance, which is caused by the passivation film formed by the chromium element in it. The passivation film can prevent water, air and chemicals from coming into direct contact with the inside of the pipe, thus effectively preventing corrosion and rust. This makes stainless steel seamless pipes perform well in harsh environments, can withstand corrosive gases, liquids and wet conditions for a long time, maintain their strength and integrity, and ensure the stable and reliable operation of the pipeline.

2. Pollution resistance: Stainless steel inox tubing has excellent pollution resistance, and its surface is smooth and not easy to adhere to impurities. This makes them ideal for use in applications where piping needs to be kept pure and free from contamination, such as in food processing, pharmaceutical manufacturing and more.

3. High Strength and Durability: Stainless steel seamless pipe has high tensile strength and yield strength, making it an extremely durable material. Capable of withstanding high pressures and loads, they excel in high pressure applications. The seamless manufacturing process also eliminates the negative impact of weld seams on the strength of the pipe, further increasing the durability of the pipe.

4. Heat resistance: Excellent performance in high temperature environment. They can withstand high temperature conditions without warping or fading, making them suitable for use in high temperature applications. This makes stainless steel seamless tubes widely used in petrochemical, energy industries and high temperature processes.

5. High reliability: Due to its excellent corrosion resistance, pollution resistance, high strength and heat resistance, high-performance stainless steel seamless pipes perform well in various fields and are widely recognized by the industry. Its high reliability ensures that the pipeline remains stable and reliable in long-term use, reducing the frequency and cost of maintenance and replacement.

Overall, the corrosion resistance, stain resistance, high strength and heat resistance of high performance stainless steel seamless tube make it ideal for high pressure, high temperature and harsh environments. Its high reliability and durability make it widely used in many industries and applications, such as chemical, petroleum, pharmaceutical, food processing and other fields. High-performance stainless steel seamless pipes provide reliable and efficient pipe solutions for various projects and projects, and meet the high requirements and diverse needs of pipe materials in different industries.

Versatility in high-quality inox tubing

With its excellent performance, stainless steel seamless pipe has multiple functions in different industries:

A. Fluid transfer

In industries such as oil and gas, chemical processing and hydraulics, high-quality inox tubing is used to transfer a variety of fluids, including aggressive chemicals and high-pressure hydraulic fluids. Their corrosion resistance and high strength properties ensure the safe and efficient flow of these substances.

B. Heat exchanger

The seamless construction of these tubes makes them ideal for heat exchangers. Whether it’s a cooling system for electronic equipment or a building’s HVAC system, stainless steel seamless tubing efficiently transfers heat while maintaining structural integrity.

C. Structural support

Stainless steel seamless tubing is integral to structural support in construction, automotive manufacturing, and aerospace applications. They provide necessary strength without adding unnecessary weight.

D. Automobile exhaust system

The automotive industry relies heavily on stainless steel seamless pipes for exhaust systems. Their high temperature and corrosion resistance ensures the longevity and performance of these critical components.

E.Medical devices

In the medical field, stainless steel seamless tubing is used to manufacture a variety of components, including surgical instruments and medical equipment. Their hygienic properties and durability are critical in these applications.

F. Precision parts

These tubing aid in the manufacture of precision components and systems, such as instrumentation tubing, where tight tolerances and reliability are critical.

Reveal the advantages of choosing seamless pipe

Choosing high-quality inox tubing can bring many advantages to your project and application:

A. to increase strength

The seamless construction eliminates welds, making these tubes stronger and more reliable than welded tubes.

B. Durability and longevity

Stainless Steel Seamless Tubing is durable with excellent resistance to corrosion, abrasion and tearing. This longevity reduces maintenance and replacement costs over time.

C. Precision engineering

Manufactured to tight tolerances, these tubes ensure uniform dimensions and excellent consistency, reducing the risk of errors and operational failures in projects.

D. High performance

The absence of welds means that stainless steel seamless tubing is less prone to defects or weaknesses, ensuring high performance in challenging conditions.

E. Versatility and adaptability

Available in a wide variety of sizes, grades and finishes, these tubes are versatile and can accommodate a wide range of applications across industries.

F. Hygienic properties

The non-porous surface of stainless steel seamless pipe coupled with its resistance to corrosion makes it ideal for industries such as food processing and pharmaceuticals where hygiene is critical.

Cross-Industry Applications: Precision Matters

The versatility and unique properties of stainless steel seamless tubing allow it to be used in a wide range of industries:

A.航空宇宙

重量と強度が重要な要素である航空宇宙産業 では、ステンレス鋼シームレス・チューブが航空機構 造、油圧システム、計装機器に使用されている。

B. 車

自動車メーカー各社は、排気システム、構造部品、燃料ラインなどにこれらのチューブを使用しています。その耐食性は、これらの重要な部品の寿命を保証します。

C.化学処理

ステンレス・スチール製シームレス・チューブは、腐食性の強い化学薬品に強いため、化学処理プラントで酸、アルカリ、その他の腐食性物質の搬送に不可欠です。

D.建設

建築分野では、ステンレス鋼シームレス管は、強度と美観を併せ持つことが高く評価され、構造サポート、建築部材、機械システムに使用されている。

E.飲食物

これらのチューブは衛生的な特性を持っているため、食品や飲料の加工、製品の輸送や保管に最適です。

F.ヘルスケア

医療分野では、ステンレス鋼シームレス・チューブは、その清潔性と耐久性から、手術器具、医療機器、診断機器の製造に使用されている。

G. 石油・ガス

ステンレス鋼シームレス管は、腐食性流体、油圧システム、ダウンホールツールの搬送用として、石油・ガス産業で重要な役割を果たしています。

H. 発電のため

発電施設では、ステンレス鋼シームレス管は、その高い耐熱性により、熱交換器、ボイラー管、蒸気配管に使用されている。

I.交通

運輸業界では、強度と耐食性が重要な船舶用 部品、鉄道システム、自転車フレームに至るまで、ステンレ ス鋼シームレス管が使用されている。

J.上下水道

水処理プラントや廃水処理施設では、過酷な化学環境下での耐腐食性により、これらのパイプが使用されています。

K.海洋とオフショア

海洋およびオフショア・アプリケーションでは、高品質のイノックス・チューブが過酷な塩水や厳しい気象条件に耐え、重要なサポートと安全性を提供します。

製品ショー

ステンレスシームレスチューブはドイツ、イギリス、フランス、オランダ、ベルギー、ロシア、アメリカ、韓国、日本、アラブ首長国連邦、オーストラリア、南アフリカなどに輸出されています。

ワークショップ:

当社は国内外で先進的な生産設備を持っており、完全な生産設備と先進的なプロセス技術を持っています。

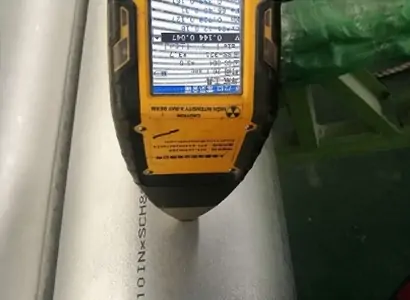

品質保証:

製品の品質を確保するために、弊社は完璧な検査設備、油圧検査、X線リアルタイム画像検出システム、スペクトル分析器、化学分析器、機械特性試験機などを備えており、GB、HG、ASTM、DIN、JISなどの規格に厳格に準拠した高品質のステンレス鋼シームレス管を生産しています。

アプリケーション

石油と化学工業は酸、アルカリ、塩などの腐食性流体を使用することが多く、ステンレスシームレスパイプはクロム、ニッケルなどの亜族金属元素を含み、その耐食性と抗酸化の特性は、流体が汚染されず、パイプが流体によって浸食されないことを保証することができます。そのため、ステンレス鋼シームレス管は主に加熱配管、加熱配管、熱交換器配管、冷却管、タワーコイルパイプ、水素化プロセスパイプライン、メタノール合成装置の合成反応器管、エチレンプラントの触媒冷却管の再生などに使用されます。