1.Basic Information and Classification 12Х2Н4А is a Russian grade of alloy structural steel (corresponding to the Chinese grade 12cr2ni4A , classified as a high-strength carburizing steel. Due to its chromium (Х) and nickel (Н) alloy elements, it combines high strength, good toughness, and wear resistance. It is primarily used for manufacturing precision parts subjected to…

Category Archives: Blog

The main benefits of bead blast surface treatment for stainless steel pipes are seen in two areas: improved material performance and cost-effectiveness. Here’s a closer look:

Stainless steel pipes are essential in the world of manufacturing, especially when we talk about industrial purposes. They are widely used in automotive, gas and oil, but also in water treatments, construction, and many other fields. The reason why they are very popular is thanks to their versatility, strength, but also great corrosion resistance. If…

Stainless steel pipes are known for their durability and rust resistance. They can easily bear high pressure and are considered ideal for various applications. However, stainless steel pipes are welded to create a strong join between pipes. However, many people don’t know how to weld stainless steel pipes.

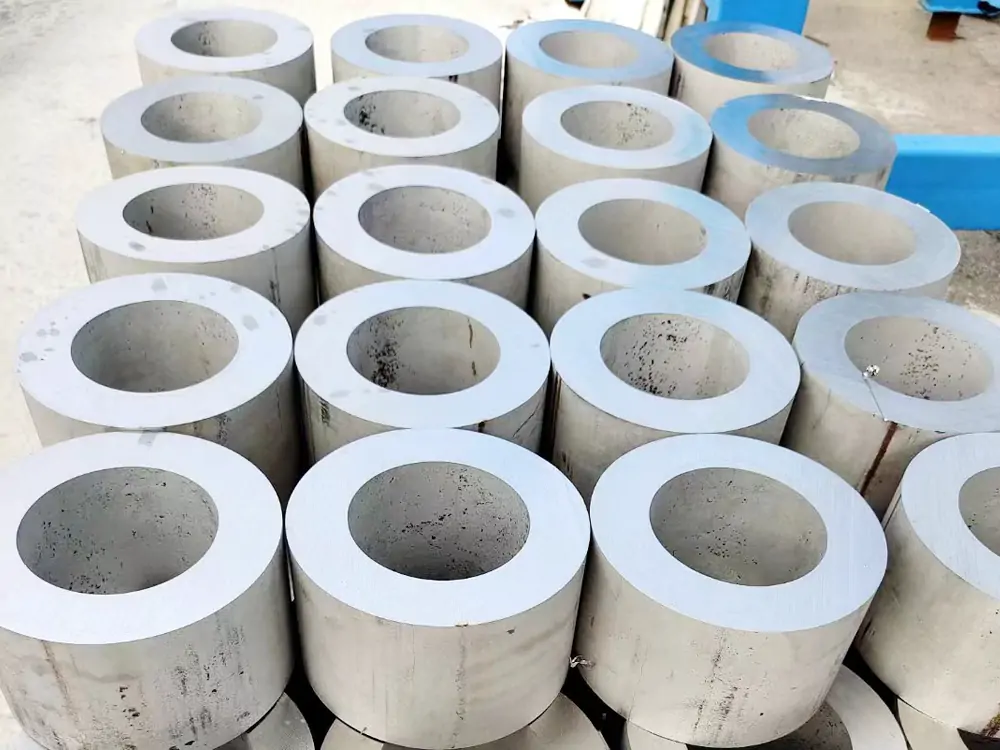

Flanges are a basic necessity in the piping industry. They are plates with holes in their corners. They allow us to connect two pipes firmly without causing any leakage. Stainless steel is a popular material used in making these flanges. However, many people seem to be consulted regarding the production process of stainless steel flanges.

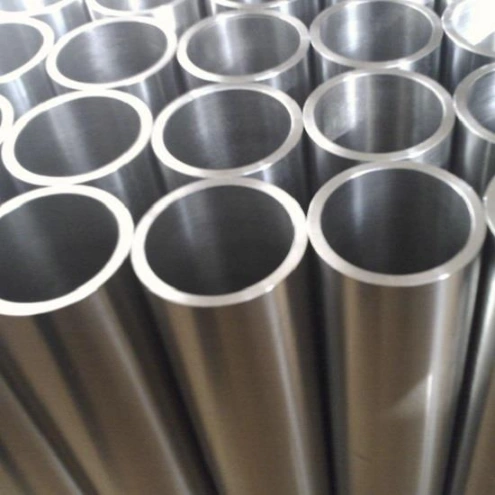

After Carbon steel, stainless steel is the most widely used material in piping. Its durability, strength, and corrosion resistance make it durable and corrosion-resistant. However, stainless steel pipes have many grades and specs. They meet the high standards of construction projects. Different stainless steel pipe grades include austenitic, ferritic, duplex, and precipitation-hardening pipes. This blog…

Stainless steels have high strength and good corrosion resistance. They are widely used in various industries. 304 and 316 stainless steel are the two most commonly used. Although they are very similar, there are some differences. You can’t tell the difference just by looking at them. What is SS 304? Stainless steel 304 is a…

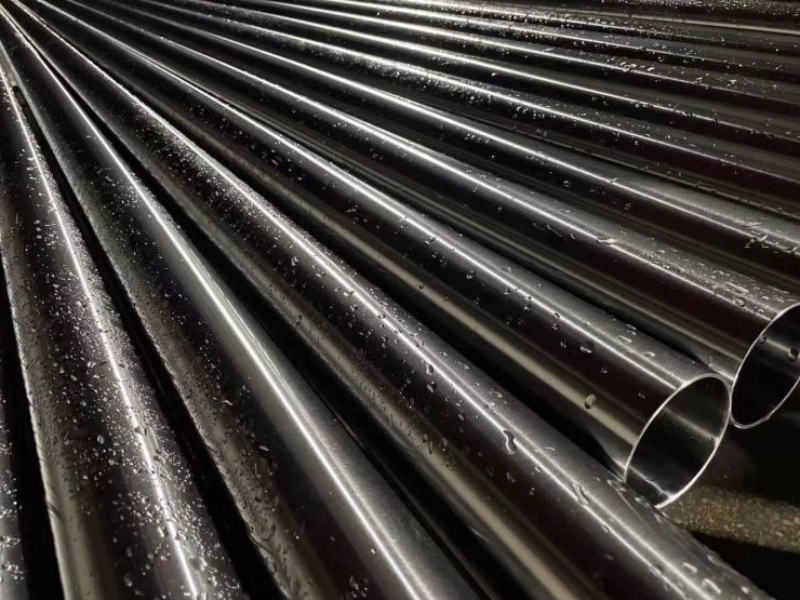

Stainless steel pipe is a kind of hollow long round steel. It is mainly used in petroleum, chemical, medical, food, light industry, mechanical instrumentation and other industrial pipelines and mechanical structural components. In addition, when the bending and torsional strength is the same, the weight is light, so it is also widely used in manufacturing…

Introduction: Thin wall stainless steel tubes, commonly known as duplex pipes, have revolutionized the landscape of industrial tubing, offering a multitude of advantages over traditional materials. This article explores the intricate details of these tubes, focusing on their metallurgical excellence, corrosion resistance, mechanical strength, versatility, and economic viability. Understanding these key attributes is crucial for…

Sch 40 Stainless Steel Pipe Sch 40 Stainless Steel Pipe is a type of stainless steel pipe with a wall thickness of 0.154 inches. It is commonly used in applications requiring high pressure and critical applications. Some of the most essential properties of Sch 40 stainless steel pipe include: Wall Thickness: The wall thickness is…

- 1

- 2