Overview of Super Duplex 2507 Pipe

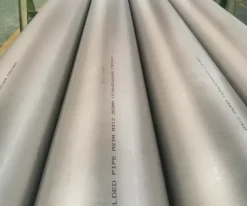

2507 duplex steel can made into weld pipe and also can made into seamless pipe,it depends on the application requirements of project.Yasco is a professional pipeline provider and can provide you with the most professional advice.Next, let’s introduce the features and applications for 2507 Duplex Pipe.

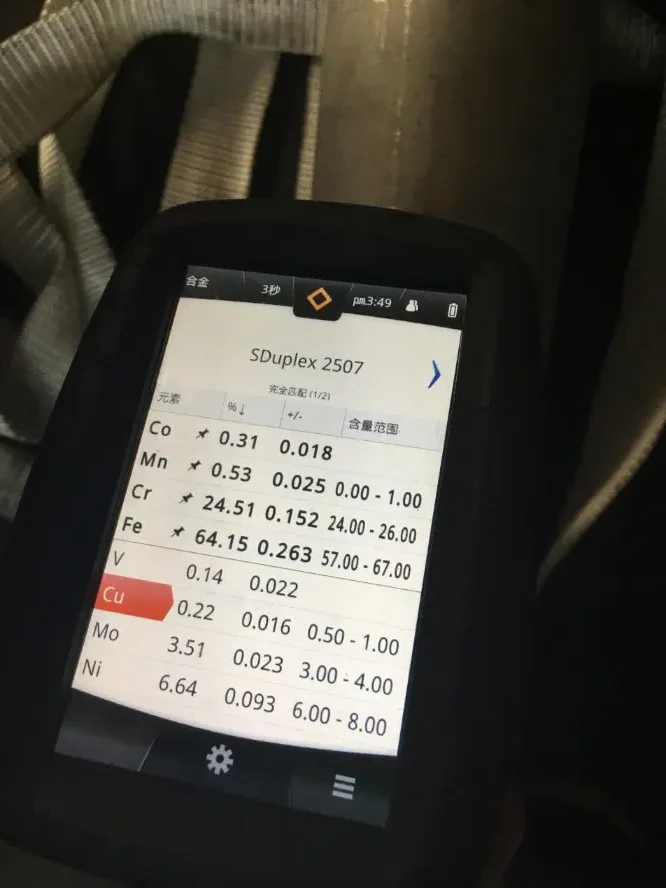

- The main chemical components are 25%(Cr)、7%(Ni)、4%(Mo)、0.25%-0.32%(N).

- High levels of chromium and molybdenum make the product more corrosion-resistant, the nitrogen enhances strength and corrosion resistance.

- High strength and mechanical properties.

Tensile strength ≥ 800 MPa, yield strength ≥ 550 MPa, significantly higher than ordinary stainless steel.Maintain stability in both high temperature (≤ 300 ° C) and low temperature environments.

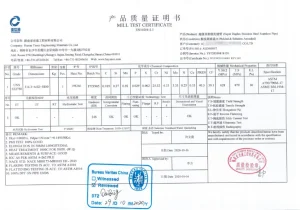

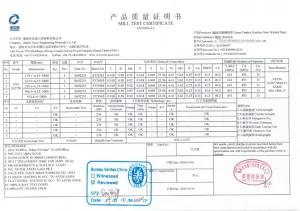

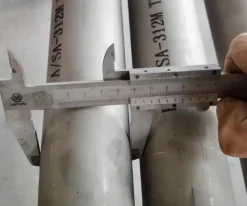

Super Duplex 2507 Pipe Mill Test Certificates

To ensure the highest quality standards, all our Super Duplex 2507 pipes undergo strict testing and certification processes. The Mill Test Certificates below provide detailed verification of material specifications, ensuring compliance with ASTM, ASME, and other industry standards.

Stainless Steel Pipe Specification Table

| Procedure | Stainless Steel Welded pipe |

| Dimensions | 10.3mm and up 1372 |

| 1/8″ and up 54″ | |

| DN6 and up DN1350 | |

| Thickness | 1.24mm and 60mm |

| SCH 5S ~SCH XXS | |

| Unit Length | As per standard or customized |

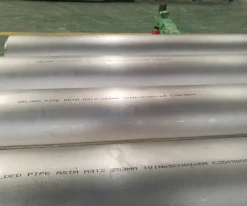

| Standards | ASTM A312, A358, A790, A249,A270…… |

| JIS G3463, G3448, JIS3468…… | |

| EN 10217-7, EN10312…… | |

| GB/T12771, HG20537, GB/T24539, GB/T19228, CJ/T151, HG20537.4…… | |

| DIN17457…… | |

| Surface | Pickling |

| Hairline | |

| Polish | |

| End Type | Plain, Bevelled, Threaded, Grooved |

| Joint Method | Fitting, Flange, Welding, Thread |

| Pipe Machining | Welding, Bending, Hole Drilling, Punching, Swaging, Tapering, Flaring, Expanding |

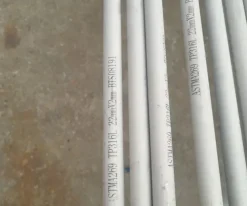

| Procedure | Stainless Steel Seamless Pipe |

| Dimensions | 10.3mm and up 914 |

| 1/8″ and up 36″ | |

| DN6 and up DN900 | |

| Thickness | 1.24mm and 60mm |

| SCH 5S ~SCH XXS | |

| Unit Length | As per standard or customized |

| Standards | GB/T14975,GB/T14976,GB13296,GB5310…… |

| ASTM A312,A213,A269,A376,A511,A959,B677,ISO 15156-3…… | |

| DIN 17456,DIN 17458,EN10216-5…… | |

| JIS G3463,JIS G3459…… | |

| According to required specification is available. | |

| Surface | Pickling |

| Sand Blast | |

| Polish | |

| End Type | Plain, Bevelled, Threaded, Grooved |

| Joint Method | Fitting, Flange, Welding,thread |

| Pipe Machining | Welding, Bending, Hole Drilling, Punching, Swaging, Tapering, Flaring, Expanding |

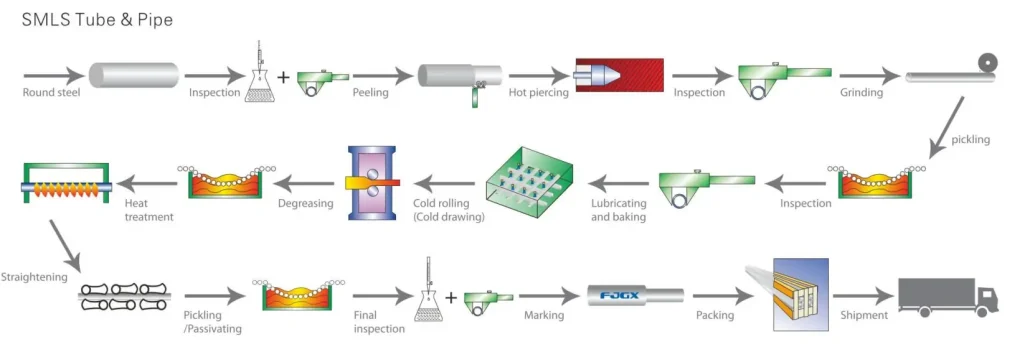

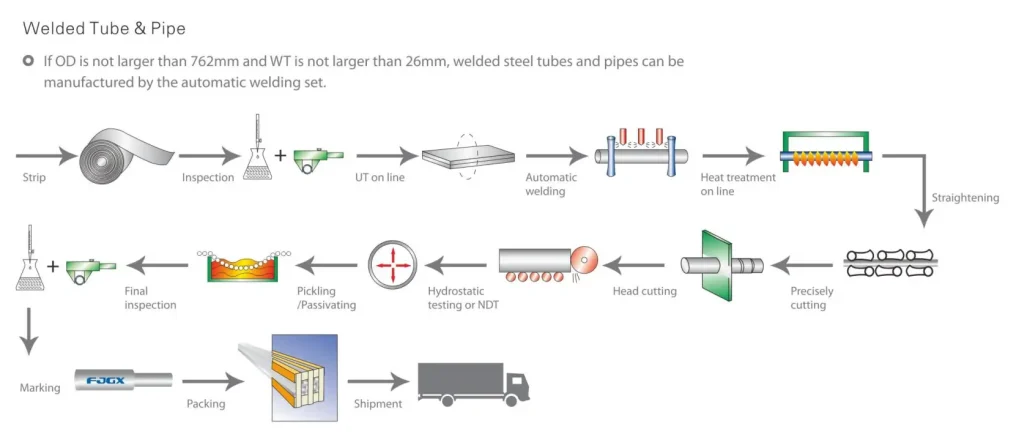

Manufacturing Processing

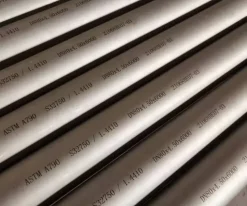

2507 Duplex Pipe: Temperature Limits, Processing, and Standards

Need to pay attention to below items, such as:

- Temperature limit: The long-term use temperature should be below 300 ° C to avoid a decrease in toughness.

- Processing control: to avoid work hardening, it is recommended to use low cutting speeds.

- The Standard specifications: We comply with international standards such as ASTM A240 and EN 1.4410.

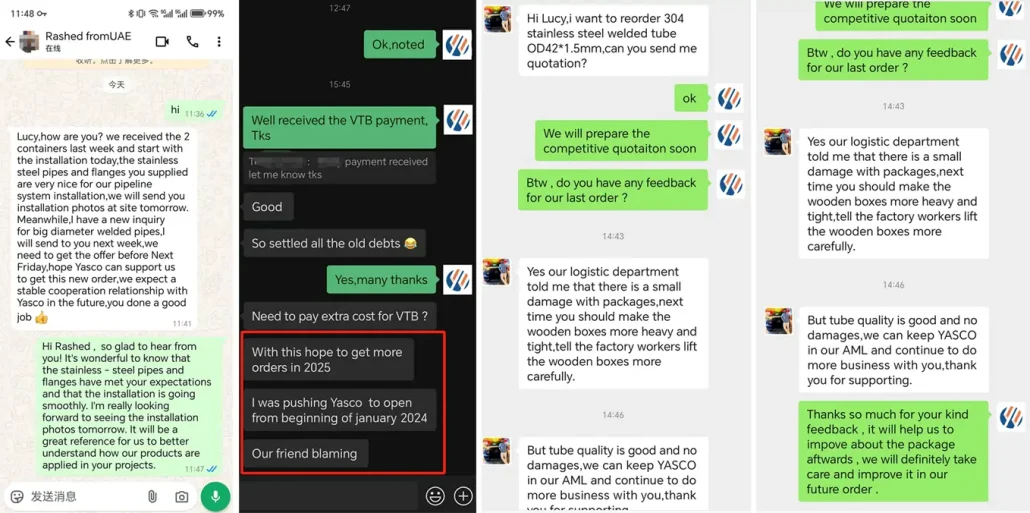

If you want other standard we also can do, you can contact with us, our email is aurora@hnyasco.com. About the market price, it is influenced by specifications, processes and QTY, the details please contact us freely.

Pipeline Prefabrication Services

We can also do pipeline prefabrication processing, this is our prefabrication workshop.

Application

About the application of 2507 duplex pipe,among them are ocean and energy engineering, such as high-pressure pipelines for ocean platforms,the bottom of the sea pipelines, and seawater desalination equipment. There are also oil and gas extraction equipment, such as heat ex-changer tubes and down hole tools.

In addition, 2057 pipes are also used in chemical and environmental protection industries, such as corrosion-resistant pressure vessels for chemical reactors, storage tanks, desalination equipment, etc. Common water treatment systems, fire sprinkler systems, etc. Other industrial uses include paper making machinery, food processing equipment, gas purification devices, and other environmental protection equipment.

Types of Packaging

Wooden Boxes

Wooden Pallet

Steel Box

Bundles

(Hexagonal or single tube)