Overview of 253MA Stainless Steel Pipe

1.Material characteristics

253MA stainless steel pipe is a heat-resistant stainless steel mainly composed of austenitic structure, designed for high temperature, high pressure and strong corrosive environments. Its chemical composition includes 20% -22% chromium (Cr), 10% -12% nickel (Ni), 1.4% -2.0% silicon (Si), 0.14% -0.20% nitrogen (N), and trace amounts of rare earth metals (REM) are added to enhance its antioxidant capacity. This material exhibits extremely high oxidation resistance, creep resistance, and corrosion resistance within the range of 850~1150 ℃, and can even withstand high temperatures of 1150 ℃ in non pressure environments.

2.Core performance advantages

High temperature performance

This material shows excellent high-temperature strength. At 900 ℃, its short-term tensile strength is more than 20% greater than that of standard stainless steels, such as 304 and 310S. It also offers great long-term creep resistance.

Powerful antioxidants: With rare earth elements, the oxide skin forms at 1150 ℃. This makes it great for tough oxidative conditions.

Corrosion resistance

It resists corrosion well in acidic, alkaline, and salty environments. This makes it great for use in chemical and petrochemical industries.

Processing and Welding

Good processing performance, supporting forming processes such as drawing and rolling;

The welding process requires strict control of heat input, and post weld heat treatment is required to eliminate stress and enhance corrosion resistance.

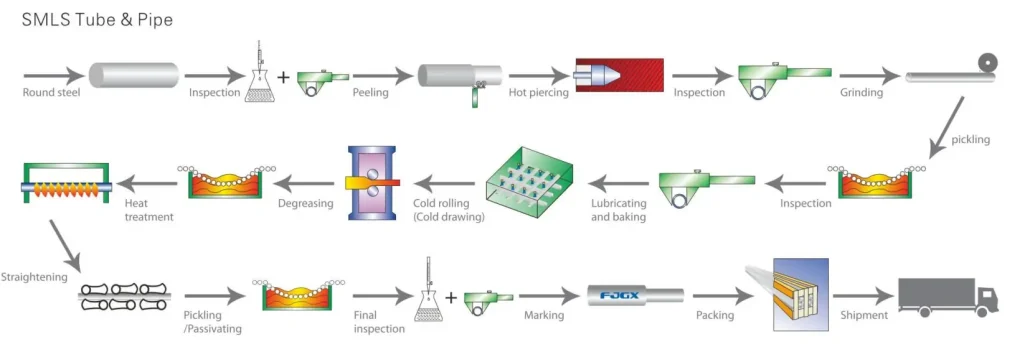

3.253MA stainless steel seamless pipe is produced through the following process.

Melting and casting: precise control of composition ratio to ensure alloy uniformity.

Hot rolling/cold rolling: forming seamless billets, combined with solution treatment to optimize microstructure stability.

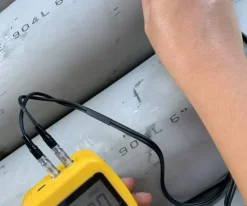

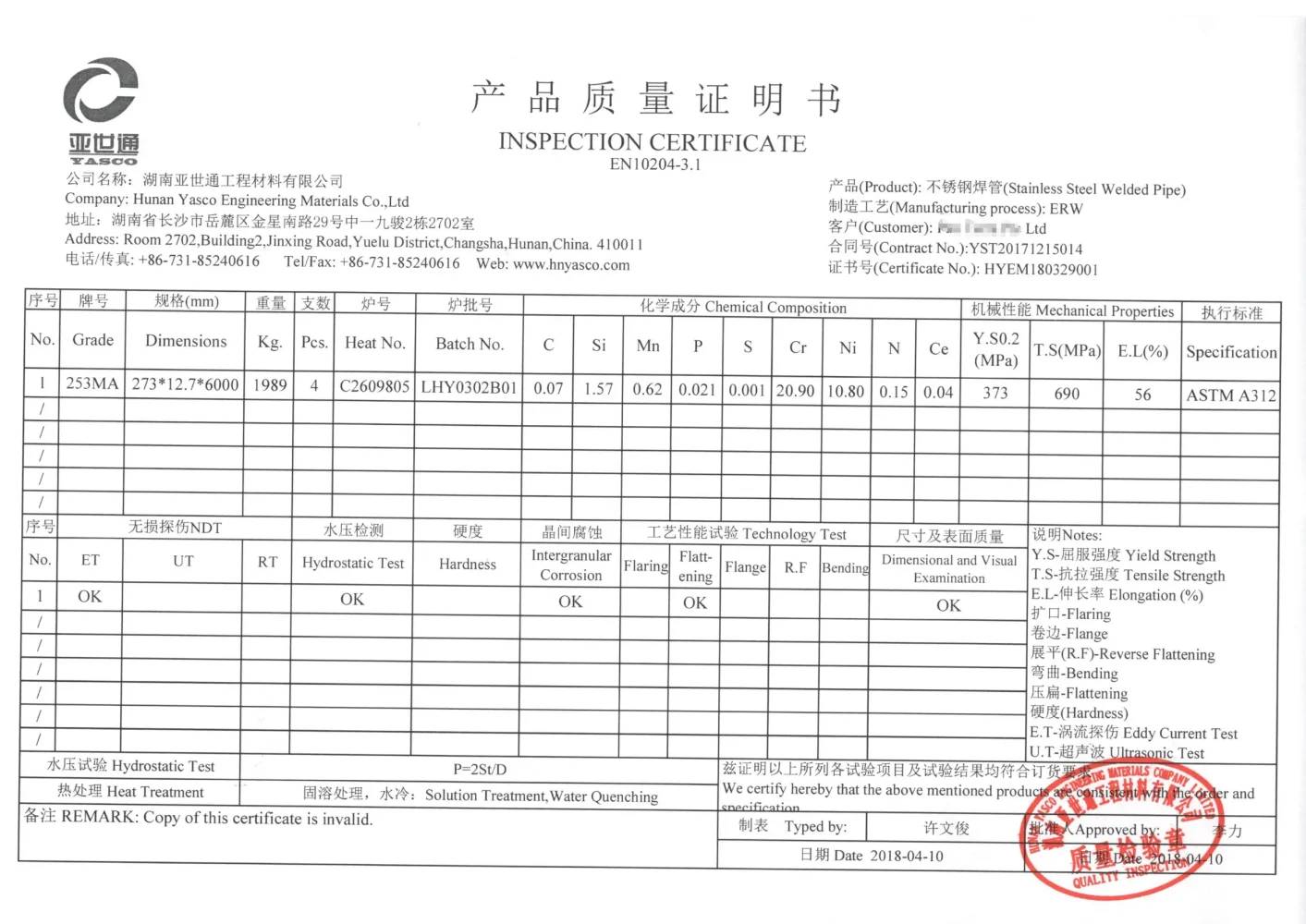

Quality inspection: including non-destructive testing, mechanical property testing, and chemical composition analysis.

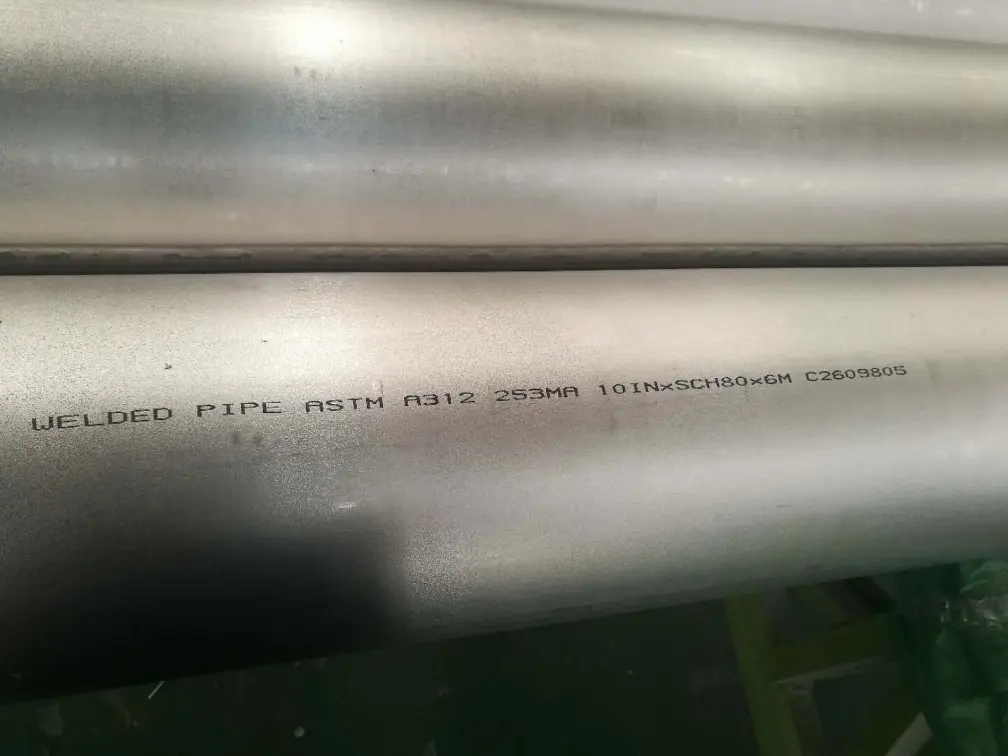

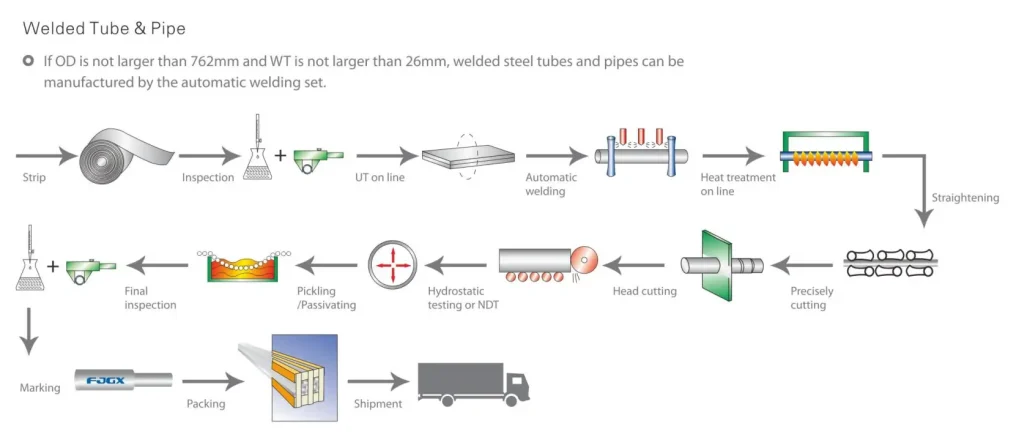

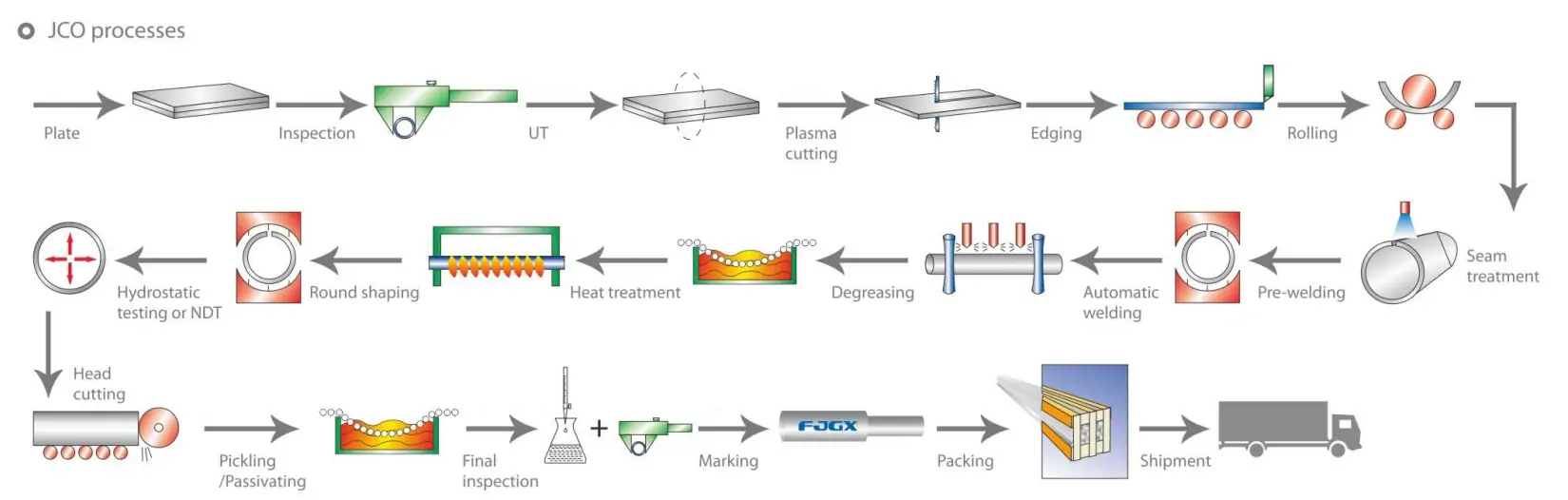

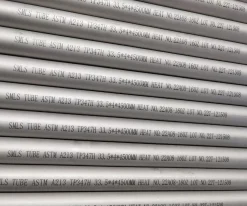

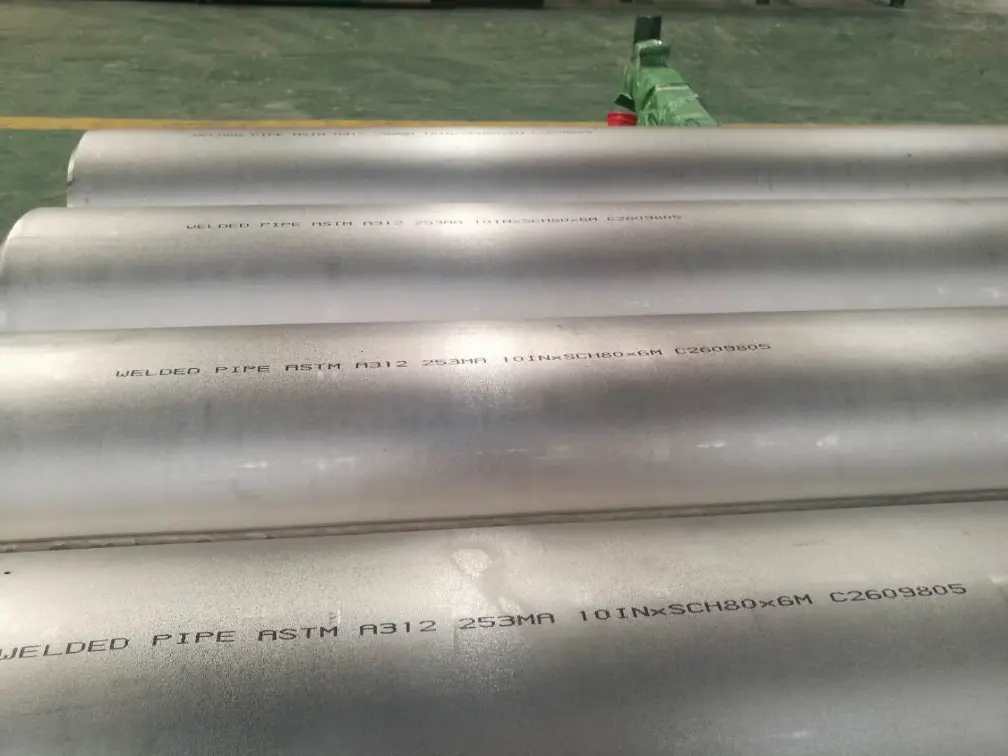

We also can produce 253MA stainless steel welded pipe,welcome to visit our factory.

Manufacturing Processing

Applications of 253MA Stainless Steel Pipe

Energy industry: high temperature and pressure scenarios such as gas boiler flues, nuclear reactor components, and superheater pipelines;

Industrial equipment: sintering equipment, blast furnaces, heat treatment furnaces, and continuous casting equipment;

Chemical industry: environments with strong corrosive media such as refining equipment and chemical reactors.

Comparison with other materials

Compared with 254SMO stainless steel, 253MA has a lower nickel content, but achieves better high-temperature oxidation resistance and cost-effectiveness through high chromium, nitrogen, and rare earth elements; And 254SMO focuses on the corrosion resistance of extreme corrosive environments (such as seawater).

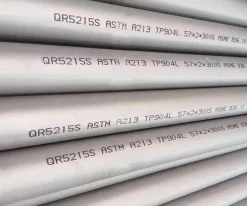

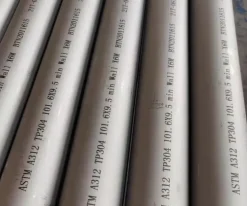

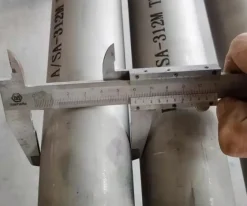

Specifications and standards

253MA stainless steel welded pipe product specifications: outer diameter of 10~1372mm(or more), wall thickness of 1.2~140mm(or more), customizable rectangular pipes and other irregular cross-sections;

Stainless Steel Pipe Specification Table

| Procedure | Stainless Steel Welded pipe |

| Dimensions | 10.3mm and up 1372 |

| 1/8″ and up 54″ | |

| DN6 and up DN1350 | |

| Thickness | 1.24mm and 60mm |

| SCH 5S ~SCH XXS | |

| Unit Length | As per standard or customized |

| Standards | ASTM A312, A358, A790, A249,A270…… |

| JIS G3463, G3448, JIS3468…… | |

| EN 10217-7, EN10312…… | |

| GB/T12771, HG20537, GB/T24539, GB/T19228, CJ/T151, HG20537.4…… | |

| DIN17457…… | |

| Surface | Pickling |

| Hairline | |

| Polish | |

| End Type | Plain, Bevelled, Threaded, Grooved |

| Joint Method | Fitting, Flange, Welding, Thread |

| Pipe Machining | Welding, Bending, Hole Drilling, Punching, Swaging, Tapering, Flaring, Expanding |

| Procedure | Stainless Steel Seamless Pipe |

| Dimensions | 10.3mm and up 914 |

| 1/8″ and up 36″ | |

| DN6 and up DN900 | |

| Thickness | 1.24mm and 60mm |

| SCH 5S ~SCH XXS | |

| Unit Length | As per standard or customized |

| Standards | GB/T14975,GB/T14976,GB13296,GB5310…… |

| ASTM A312,A213,A269,A376,A511,A959,B677,ISO 15156-3…… | |

| DIN 17456,DIN 17458,EN10216-5…… | |

| JIS G3463,JIS G3459…… | |

| According to required specification is available. | |

| Surface | Pickling |

| Sand Blast | |

| Polish | |

| End Type | Plain, Bevelled, Threaded, Grooved |

| Joint Method | Fitting, Flange, Welding,thread |

| Pipe Machining | Welding, Bending, Hole Drilling, Punching, Swaging, Tapering, Flaring, Expanding |

Types of Packaging

Wooden Boxes

Wooden Pallet

Steel Box

Bundles

(Hexagonal or single tube)