Overview of 304 Stainless Steel Pipe

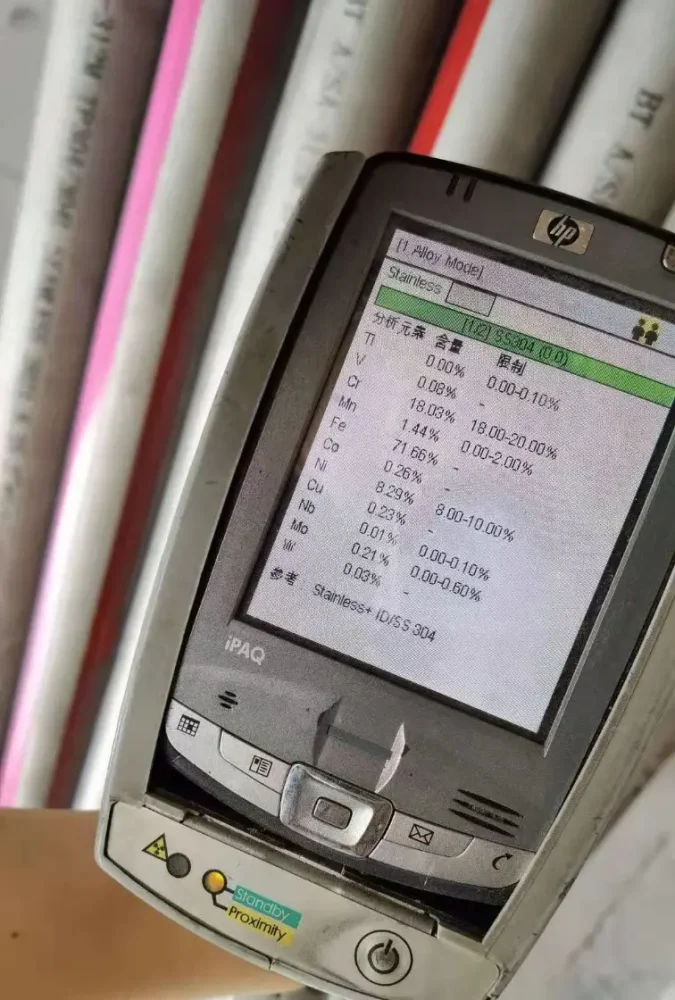

304 stainless steel pipe is a versatile and widely used material in various industries due to its excellent corrosion resistance, high durability, and ease of fabrication. Made from an austenitic stainless steel alloy containing 18% chromium and 8% nickel, 304 stainless steel pipes exhibit superior resistance to oxidation, rust, and staining. The 304 pipes are also known for their high strength and ability to withstand extreme temperatures, both high and low.

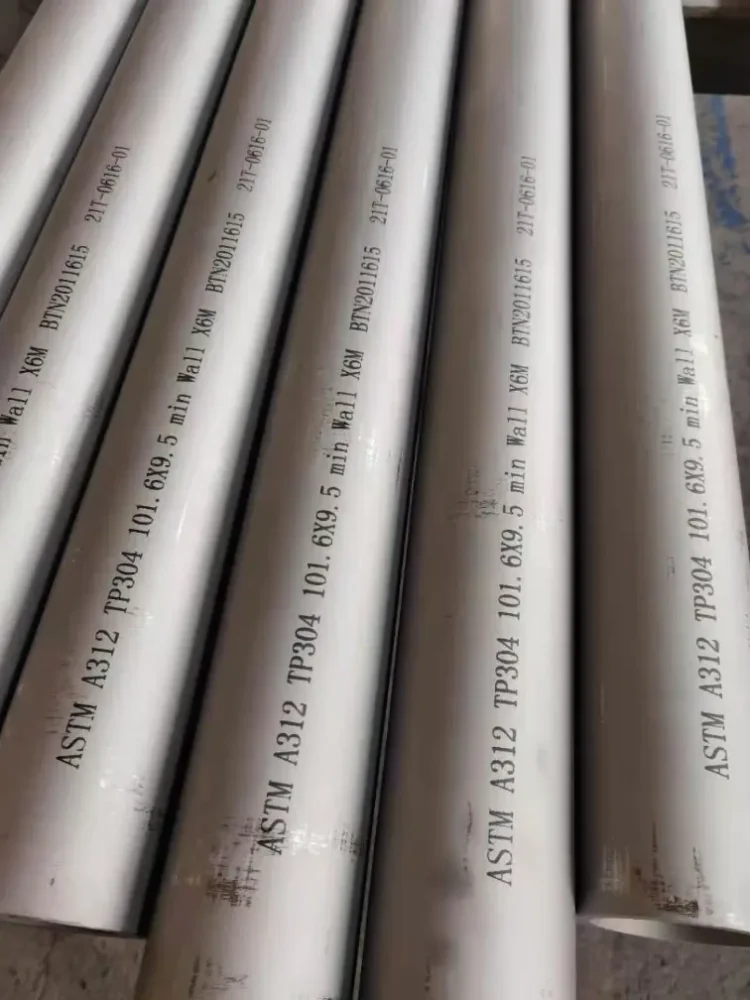

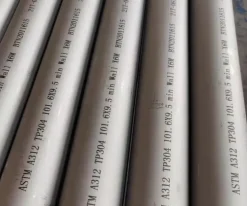

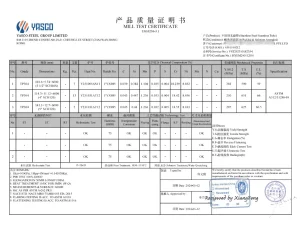

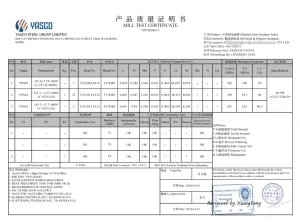

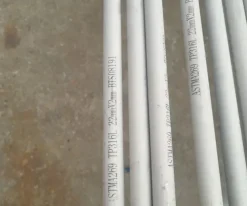

304 Stainless Steel Pipe Mill Test Certificates

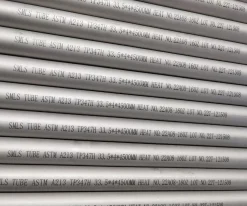

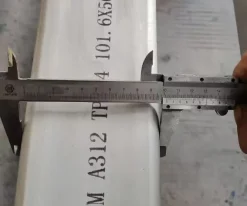

To ensure the highest quality standards, all our product 304 stainless steel pipe undergo strict testing and certification processes. The Mill Test Certificates below provide detailed verification of material specifications, ensuring compliance with ASTMA312/312M-19, and other industry standards.

Two Stainless Steel Pipe Specification Table (Classified by Process)

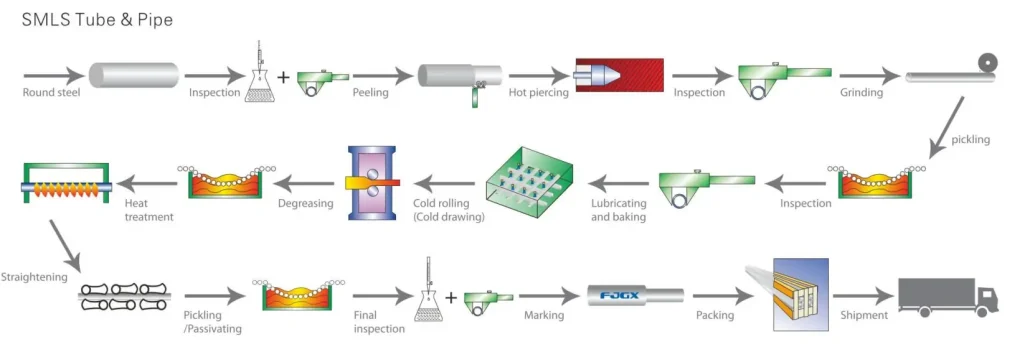

- Seamless pipe: manufactured through hot rolling, cold rolling, or cold drawing processes, suitable for high-pressure, high-precision scenarios.

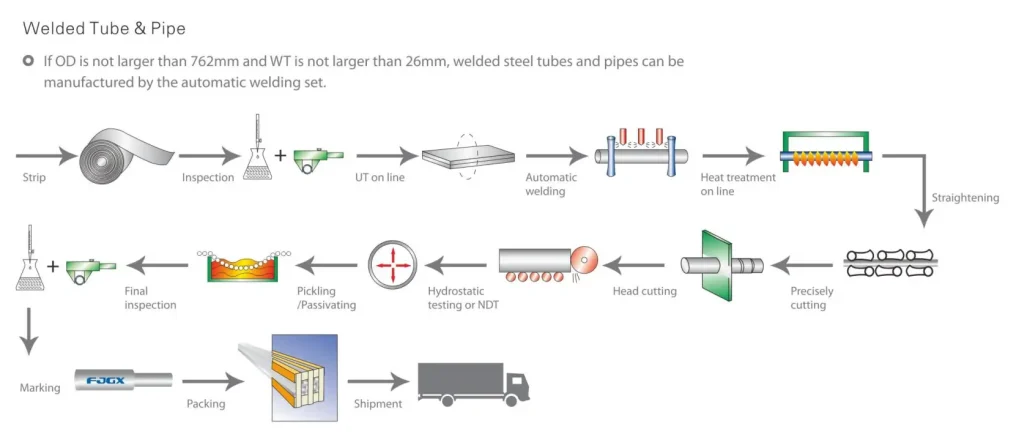

- Welded pipe: using straight seam or spiral welding technology, mostly used for decoration and low-pressure pipeline systems.

| Procedure | Stainless Steel Welded pipe |

| Dimensions | 10.3mm and up 1372 |

| 1/8″ and up 54″ | |

| DN6 and up DN1350 | |

| Thickness | 1.24mm and 60mm |

| SCH 5S ~SCH XXS | |

| Unit Length | As per standard or customized |

| Standards | ASTM A312, A358, A790, A249,A270…… |

| JIS G3463, G3448, JIS3468…… | |

| EN 10217-7, EN10312…… | |

| GB/T12771, HG20537, GB/T24539, GB/T19228, CJ/T151, HG20537.4…… | |

| DIN17457…… | |

| Surface | Pickling |

| Hairline | |

| Polish | |

| End Type | Plain, Bevelled, Threaded, Grooved |

| Joint Method | Fitting, Flange, Welding, Thread |

| Pipe Machining | Welding, Bending, Hole Drilling, Punching, Swaging, Tapering, Flaring, Expanding |

| Procedure | Stainless Steel Seamless Pipe |

| Dimensions | 10.3mm and up 914 |

| 1/8″ and up 36″ | |

| DN6 and up DN900 | |

| Thickness | 1.24mm and 60mm |

| SCH 5S ~SCH XXS | |

| Unit Length | As per standard or customized |

| Standards | GB/T14975,GB/T14976,GB13296,GB5310…… |

| ASTM A312,A213,A269,A376,A511,A959,B677,ISO 15156-3…… | |

| DIN 17456,DIN 17458,EN10216-5…… | |

| JIS G3463,JIS G3459…… | |

| According to required specification is available. | |

| Surface | Pickling |

| Sand Blast | |

| Polish | |

| End Type | Plain, Bevelled, Threaded, Grooved |

| Joint Method | Fitting, Flange, Welding,thread |

| Pipe Machining | Welding, Bending, Hole Drilling, Punching, Swaging, Tapering, Flaring, Expanding |

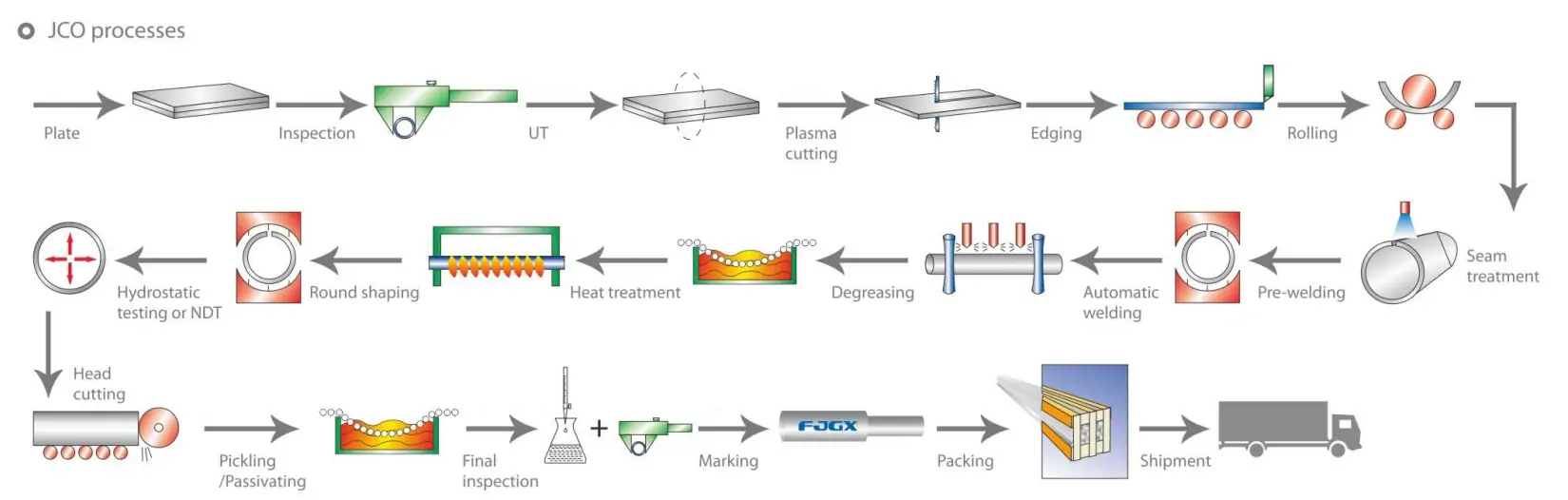

3 Different Manufacturing Processing of 304 Stainless Steel Pipe

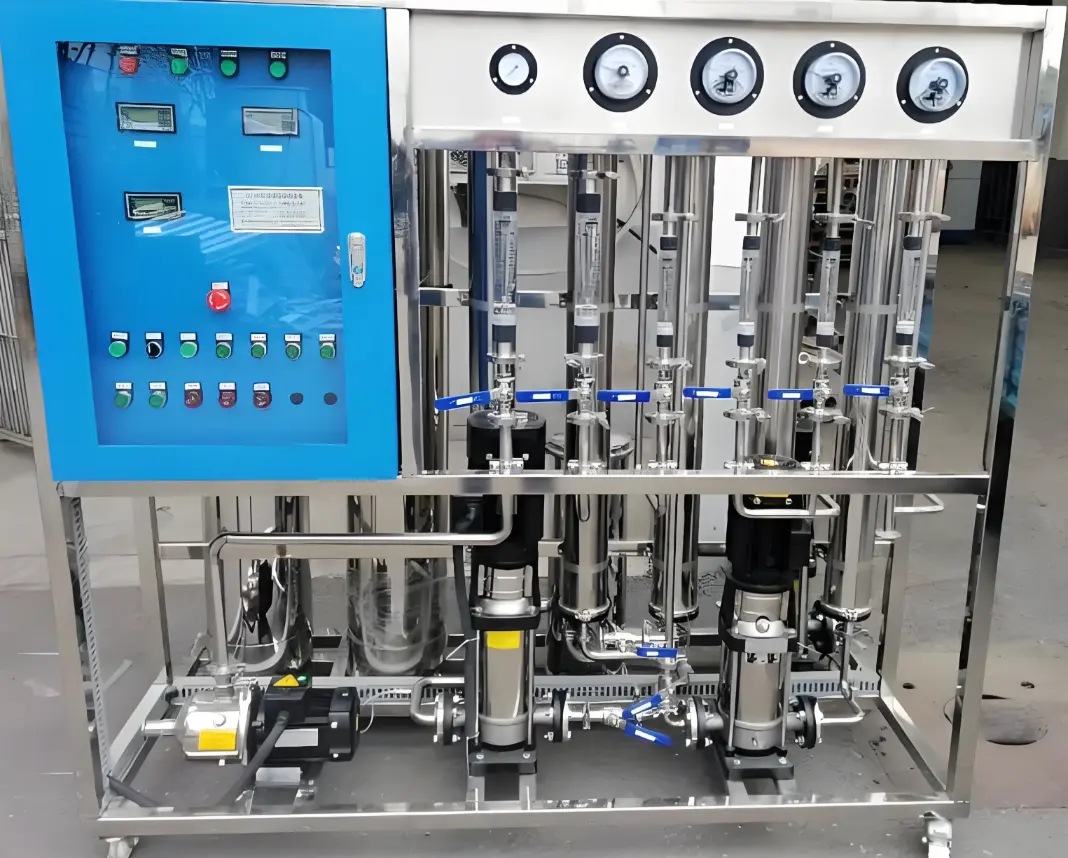

Applications of 304 Stainless Steel Pipe

Industrial equipment

Chemical, energy, and food processing equipment (such as reaction vessels, heat exchangers).

Architectural decoration

The surfaces of railings, handrails, etc. can be polished or brushed.

Medical industry

Surgical instruments, sterile equipment (must meet food grade standards).

Types of Packaging

Wooden Boxes

Wooden Pallet

Steel Box

Bundles

(Hexagonal or single tube)

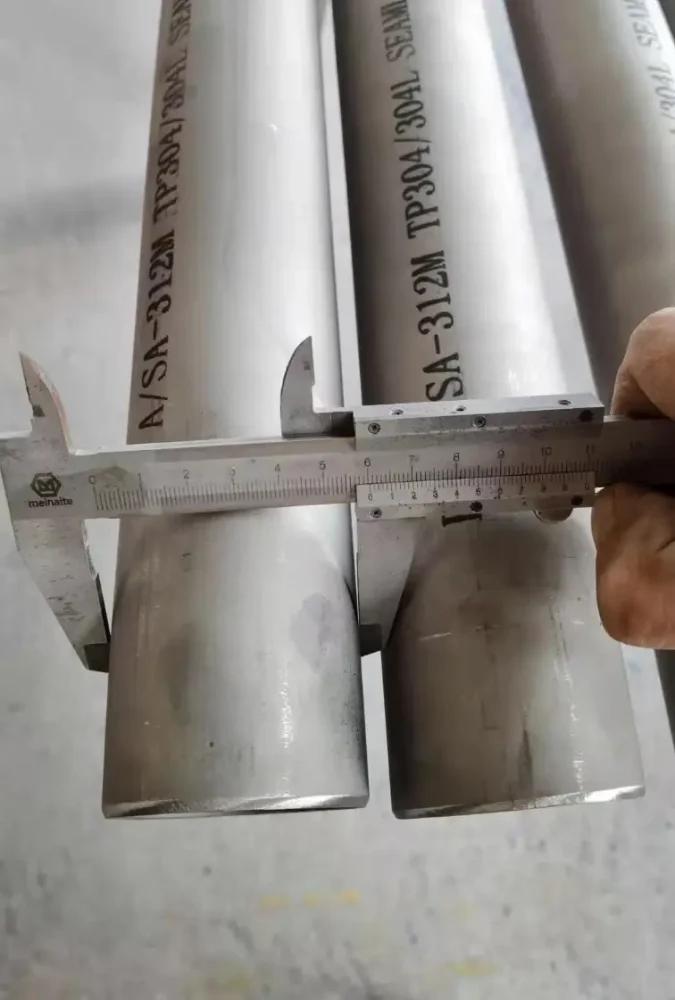

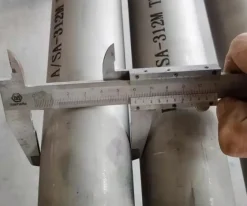

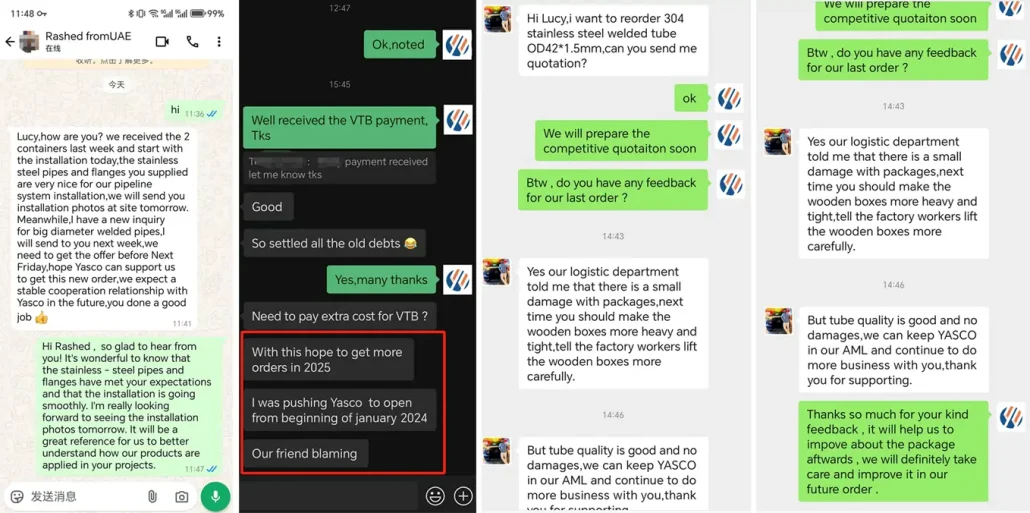

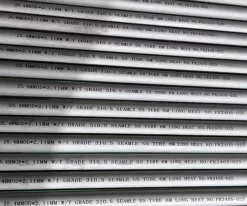

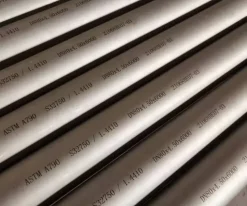

More displays of 304 stainless steel pipes

We have a lot choice about the sizes and surface for your reference , customization is also OK .

Any query or inquiry about the 304 stainless steel pipes , just let us know freely .

We do believe our products will benefit your company , You can reach us at any time by aurora@hnyasco.com