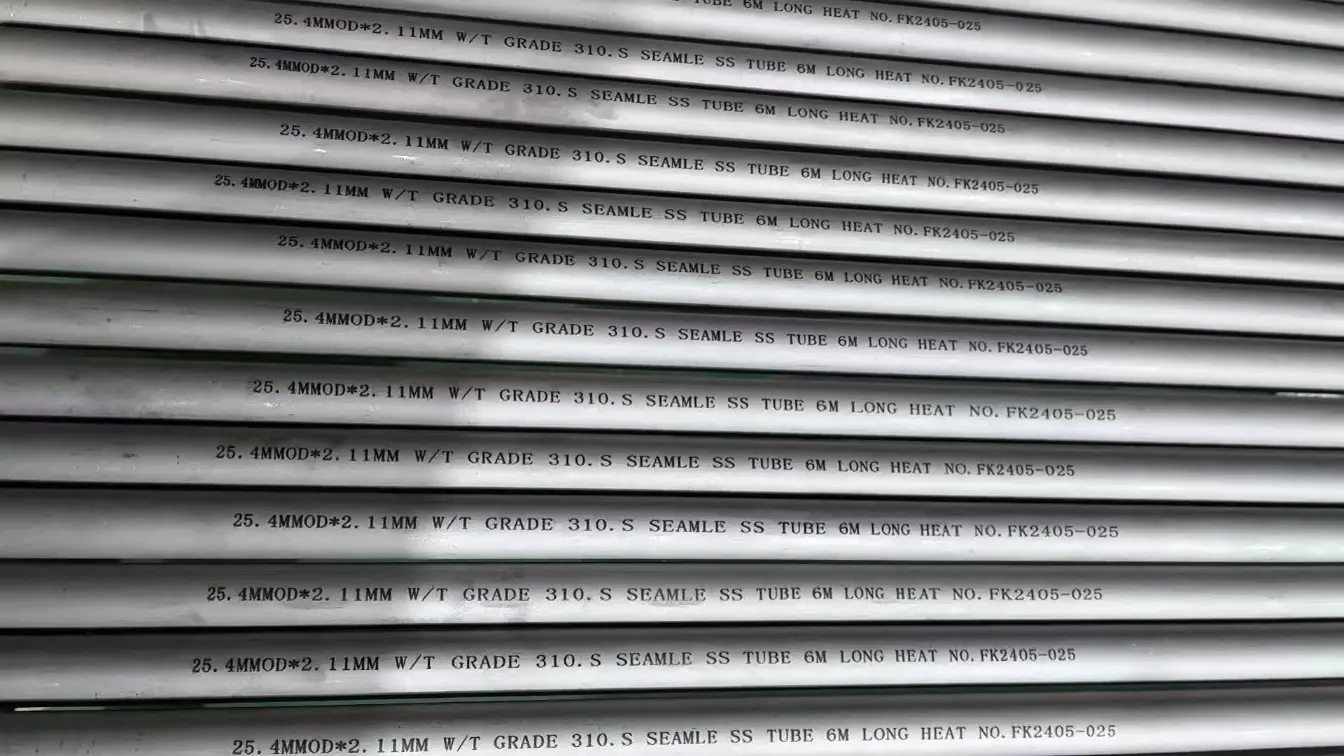

Overview of 310s Stainless Steel Pipe

Yasco 310S Stainless Steel Pipes, a high-performance solution designed for applications requiring exceptional heat resistance, corrosion resistance, and durability. Known for its superior properties, 310S stainless steel is a popular choice for industries operating in extreme environments.

What is 310S Stainless Steel?

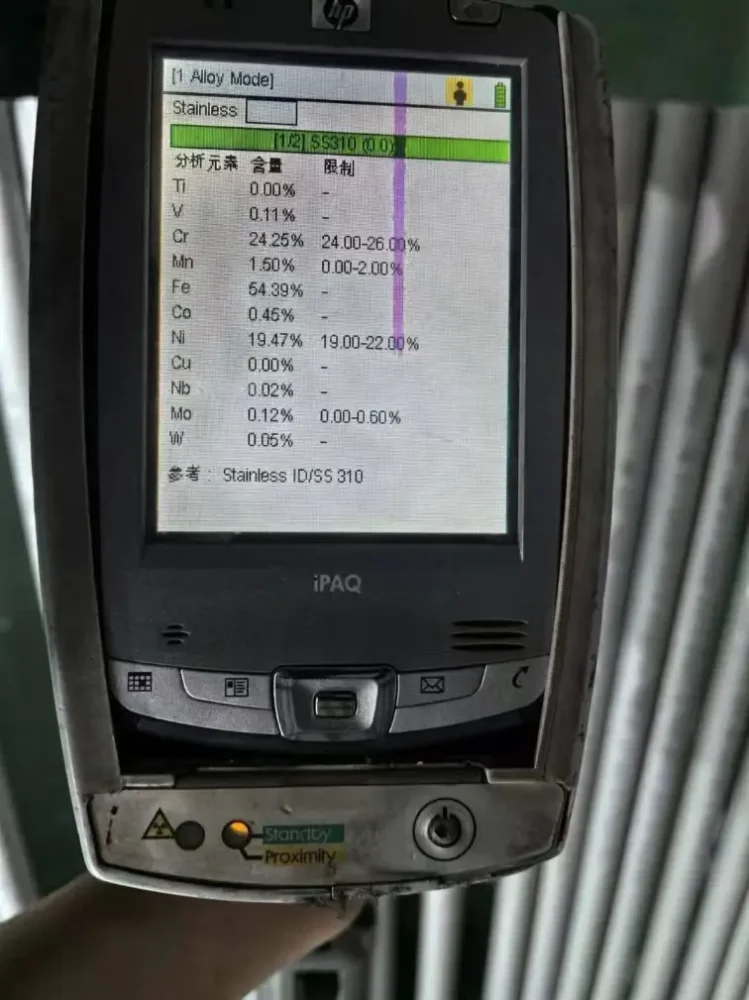

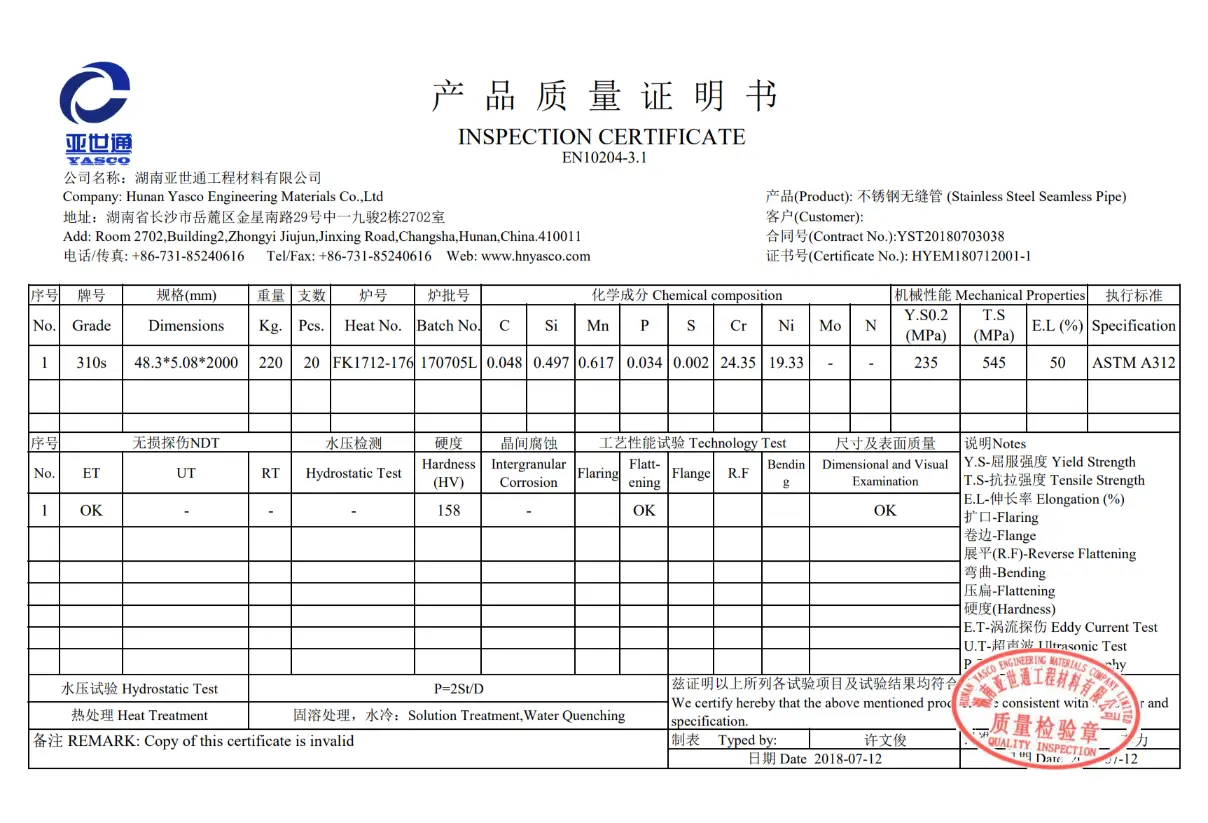

310S stainless steel is an austenitic chromium-nickel alloy with high levels of chromium and nickel, making it highly resistant to oxidation, corrosion, and high-temperature scaling. It is a low-carbon version of the 310 alloy, which enhances its weldability and prevents carbide precipitation during welding.Main content :Chromium (Cr): 24.0 – 26.0 , Nickel (Ni):19.0 – 22.0 ,Carbon (C),≤ 0.08 ;Manganese (Mn)≤ 2.0,Silicon (Si),≤ 1.5,Phosphorus (P)≤ 0.045,Sulfur (S)≤ 0.03

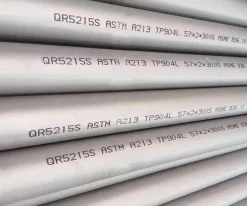

Stainless Steel Pipe Specification Table

| Procedure | Stainless Steel Welded pipe |

| Dimensions | 10.3mm and up 1372 |

| 1/8″ and up 54″ | |

| DN6 and up DN1350 | |

| Thickness | 1.24mm and 60mm |

| SCH 5S ~SCH XXS | |

| Unit Length | As per standard or customized |

| Standards | ASTM A312, A358, A790, A249,A270…… |

| JIS G3463, G3448, JIS3468…… | |

| EN 10217-7, EN10312…… | |

| GB/T12771, HG20537, GB/T24539, GB/T19228, CJ/T151, HG20537.4…… | |

| DIN17457…… | |

| Surface | Pickling |

| Hairline | |

| Polish | |

| End Type | Plain, Bevelled, Threaded, Grooved |

| Joint Method | Fitting, Flange, Welding, Thread |

| Pipe Machining | Welding, Bending, Hole Drilling, Punching, Swaging, Tapering, Flaring, Expanding |

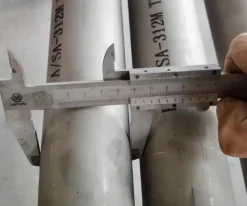

| Procedure | Stainless Steel Seamless Pipe |

| Dimensions | 10.3mm and up 914 |

| 1/8″ and up 36″ | |

| DN6 and up DN900 | |

| Thickness | 1.24mm and 60mm |

| SCH 5S ~SCH XXS | |

| Unit Length | As per standard or customized |

| Standards | GB/T14975,GB/T14976,GB13296,GB5310…… |

| ASTM A312,A213,A269,A376,A511,A959,B677,ISO 15156-3…… | |

| DIN 17456,DIN 17458,EN10216-5…… | |

| JIS G3463,JIS G3459…… | |

| According to required specification is available. | |

| Surface | Pickling |

| Sand Blast | |

| Polish | |

| End Type | Plain, Bevelled, Threaded, Grooved |

| Joint Method | Fitting, Flange, Welding,thread |

| Pipe Machining | Welding, Bending, Hole Drilling, Punching, Swaging, Tapering, Flaring, Expanding |

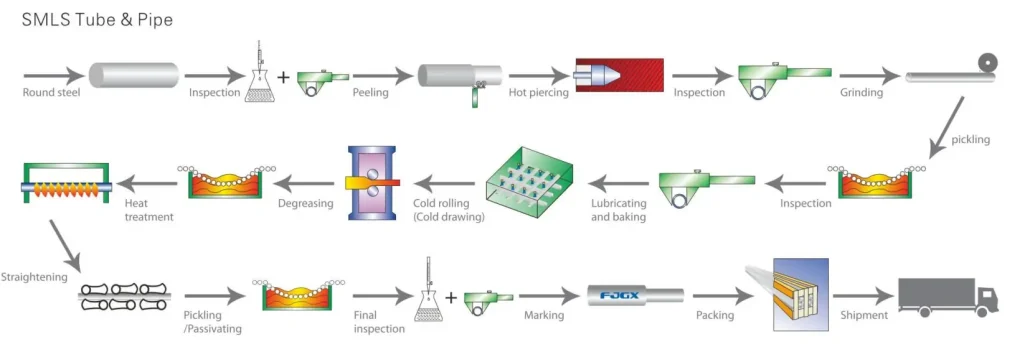

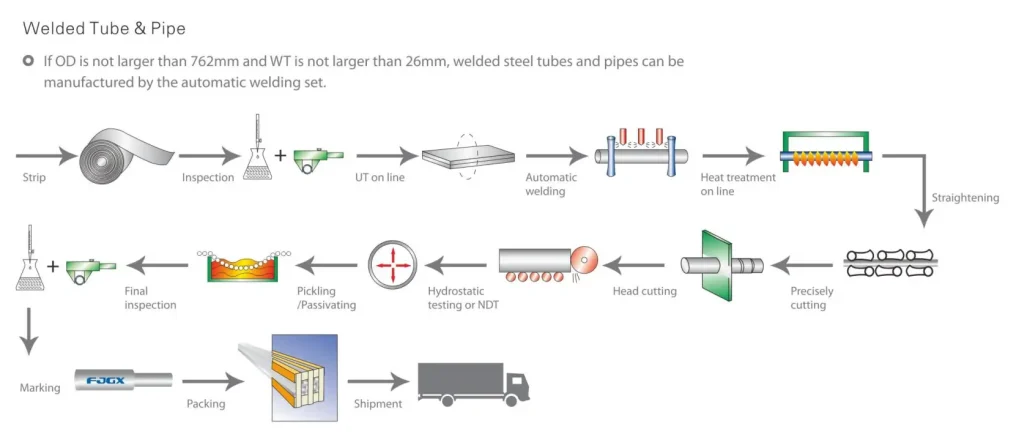

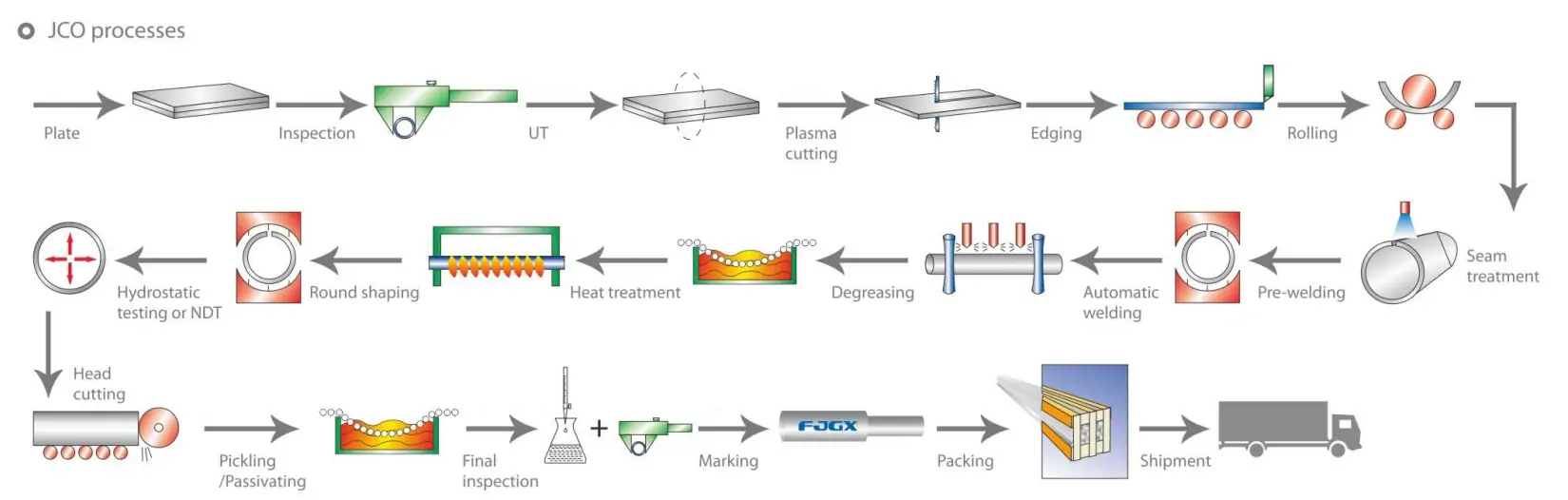

Manufacturing Processing

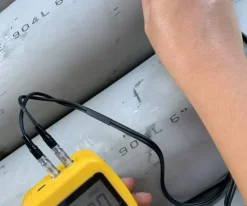

- Seamless pipe: manufactured through hot rolling, cold rolling, or cold drawing processes, suitable for high-pressure, high-precision scenarios.

- Welded pipe: using straight seam or spiral welding technology, mostly used for decoration and low-pressure pipeline systems.

Nice Physical Properties of 310S Stainless Steel

High-Temperature Resistance:

1.Can withstand temperatures up to 1150°C (2100°F) in continuous service and 1035°C (1900°F) in intermittent service.

2.Maintains strength and oxidation resistance at elevated temperatures.

Oxidation Resistance:

Forms a stable chromium oxide layer that protects against oxidation and scaling in high-temperature environments.

Corrosion Resistance:

Resists corrosion from acids, alkalis, and other corrosive media, making it suitable for chemical processing and industrial applications.

Mechanical Properties:

High tensile and yield strength ensure durability and reliability under mechanical stress.

Excellent ductility and toughness allow for easy fabrication and welding.

Low Carbon Content:

Prevents carbide precipitation during welding, ensuring strong and durable welds without the risk of intergranular corrosion.

Applications of 310S Stainless Steel:

Heat Treatment Equipment: Furnace components, radiant tubes, and heat exchangers.

Chemical Processing: Reactors, piping systems, and storage tanks.

Power eneration: Boiler components, exhaust systems, and turbine parts.

Petrochemical Industry: Refineries and high-temperature processing units.

Aerospace and Automotive: Exhaust systems and high-temperature components.

Food Processing: Ovens, conveyors, and other high-temperature equipment.