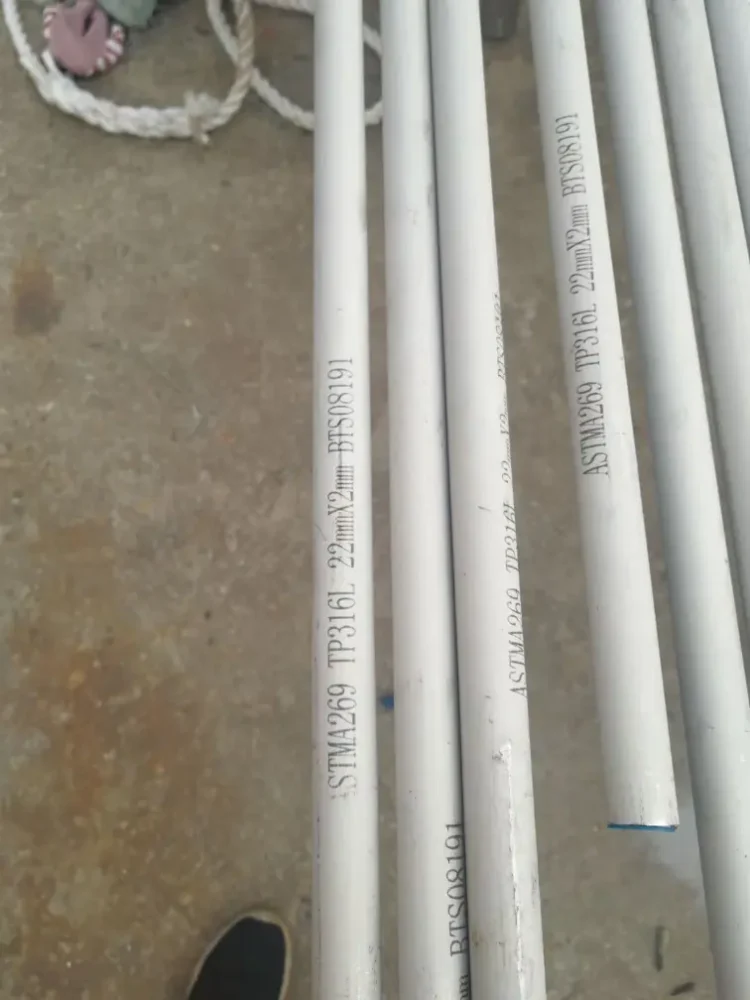

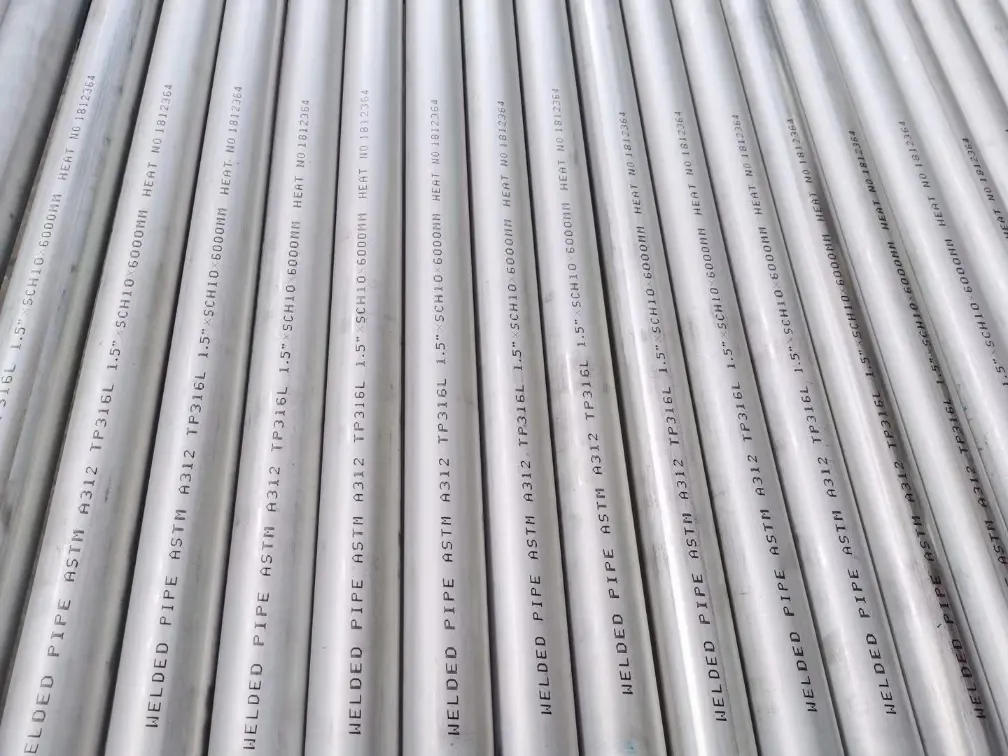

Overview of 316L Stainless Steel Tubing

Yasco 316L stainless steel industrial pipes are engineered for superior performance in demanding environments. Made from a high-quality austenitic stainless steel alloy containing 16% chromium, 10% nickel, and 2% molybdenum, these pipes offer exceptional corrosion resistance, particularly against chlorides and acidic substances.

Inspection Methods for 316L Stainless Steel Pipes

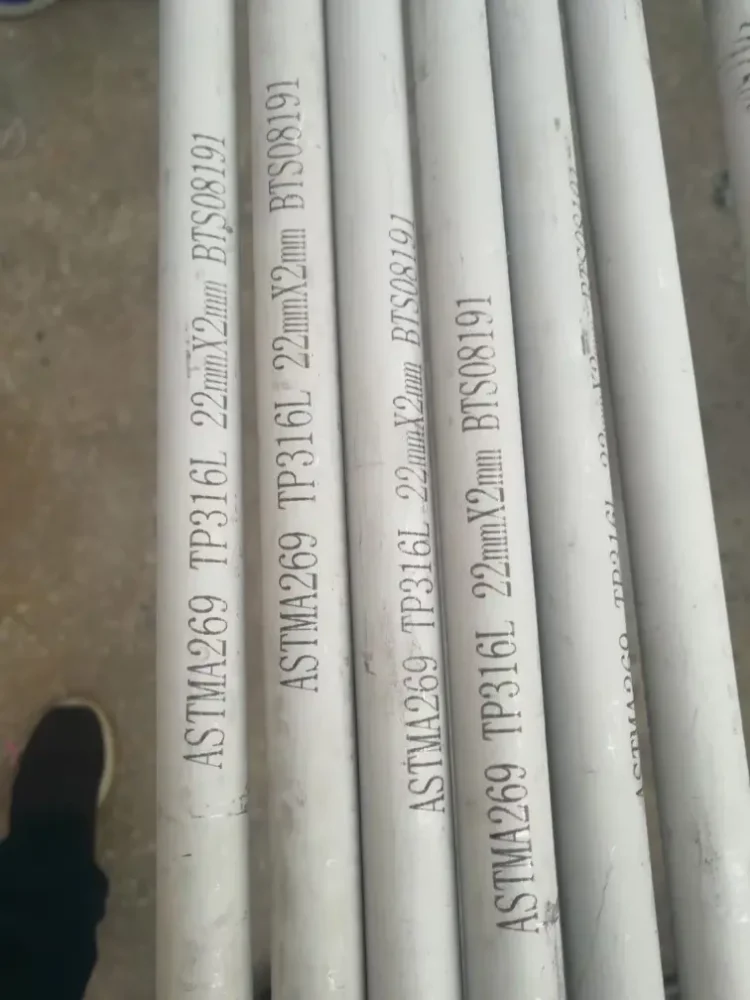

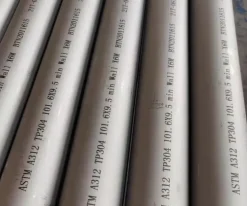

1.Appearance inspection

The surface should be smooth without scratches, pits, oxide layers or rust spots, and the two ends of the cut should be flat without burrs.

The weld area needs to be inspected for defects such as cracks and pores, and the surface color should be uniform and consistent.

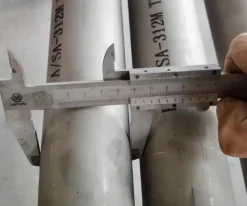

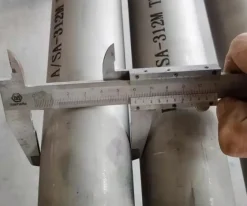

2.Dimensional measurement

Use tools such as calipers and micrometers to measure parameters such as outer diameter, wall thickness, and length to ensure compliance with national standards or contractual requirements.

Precision pipes need to be checked for ovality and straightness deviation.

3.Mechanical performance testing

Detect tensile strength (≥ 485MPa), yield strength (≥ 170MPa), and elongation (≥ 40%) through tensile testing.

Impact test verification of low-temperature toughness (applicable to special purpose pipes) 2.

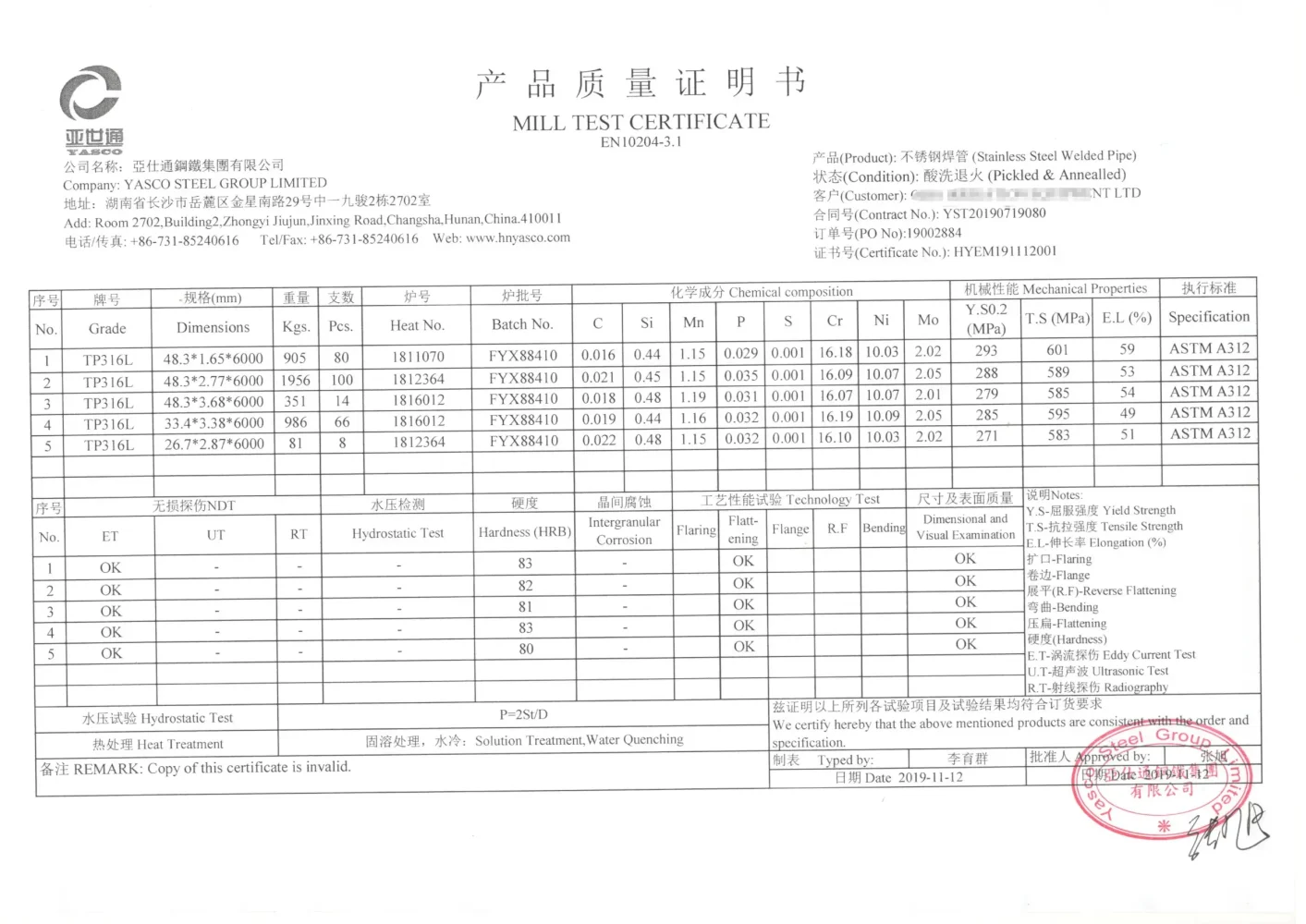

4. Chemical composition testing

Use a direct reading spectrometer or handheld XRF device to determine the content of key elements (such as Cr: 16.5-18.5%, Ni:10-14%,Mo: 2-3%), ensuring compliance with 316L standard 24.

5. Chemical reagent testing

Special identification solution (such as copper sulfate or 316L detection solution) is dropped onto the surface to determine the authenticity of the material through color changes.

6.Non destructive testing

Ultrasonic testing (UT) or eddy current testing (ET) is used to detect internal cracks, inclusions, and other defects.

Metallographic analysis: Observe grain size, inclusion distribution, and uniformity of austenite structure under a microscope.

Stainless Steel Pipe Specification Table

| Procedure | Stainless Steel Welded pipe |

| Dimensions | 10.3mm and up 1372 |

| 1/8″ and up 54″ | |

| DN6 and up DN1350 | |

| Thickness | 1.24mm and 60mm |

| SCH 5S ~SCH XXS | |

| Unit Length | As per standard or customized |

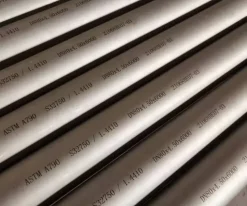

| Standards | ASTM A312, A358, A790, A249,A270…… |

| JIS G3463, G3448, JIS3468…… | |

| EN 10217-7, EN10312…… | |

| GB/T12771, HG20537, GB/T24539, GB/T19228, CJ/T151, HG20537.4…… | |

| DIN17457…… | |

| Surface | Pickling |

| Hairline | |

| Polish | |

| End Type | Plain, Bevelled, Threaded, Grooved |

| Joint Method | Fitting, Flange, Welding, Thread |

| Pipe Machining | Welding, Bending, Hole Drilling, Punching, Swaging, Tapering, Flaring, Expanding |

| Procedure | Stainless Steel Seamless Pipe |

| Dimensions | 10.3mm and up 914 |

| 1/8″ and up 36″ | |

| DN6 and up DN900 | |

| Thickness | 1.24mm and 60mm |

| SCH 5S ~SCH XXS | |

| Unit Length | As per standard or customized |

| Standards | GB/T14975,GB/T14976,GB13296,GB5310…… |

| ASTM A312,A213,A269,A376,A511,A959,B677,ISO 15156-3…… | |

| DIN 17456,DIN 17458,EN10216-5…… | |

| JIS G3463,JIS G3459…… | |

| According to required specification is available. | |

| Surface | Pickling |

| Sand Blast | |

| Polish | |

| End Type | Plain, Bevelled, Threaded, Grooved |

| Joint Method | Fitting, Flange, Welding,thread |

| Pipe Machining | Welding, Bending, Hole Drilling, Punching, Swaging, Tapering, Flaring, Expanding |

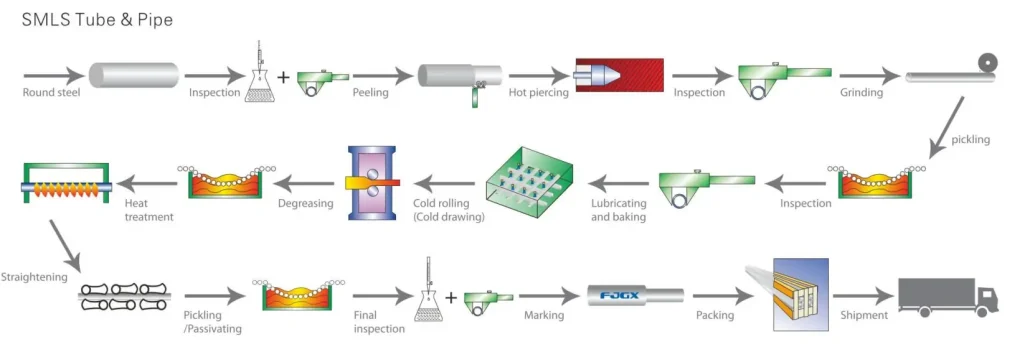

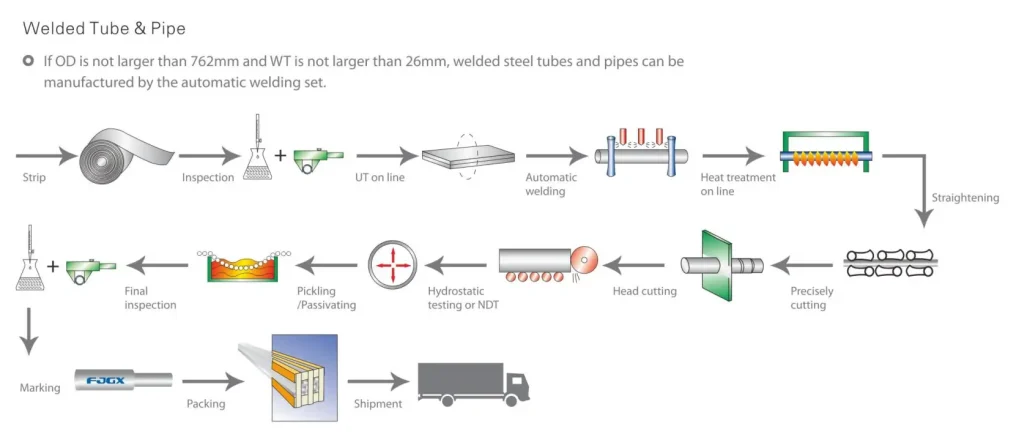

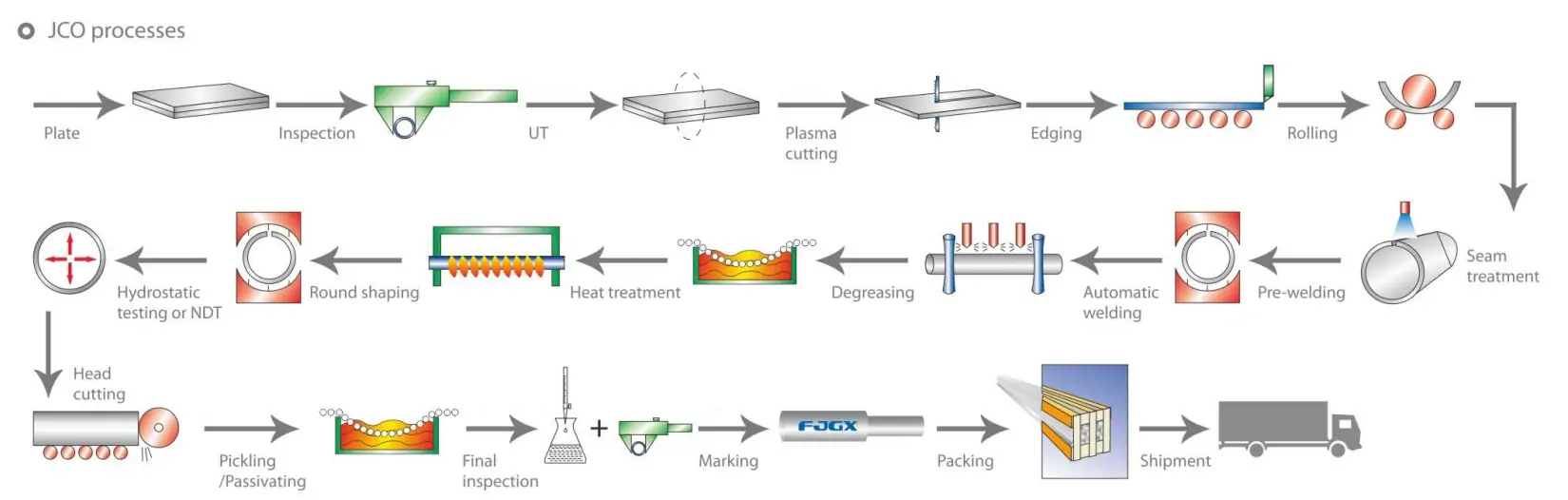

Manufacturing Processing

Types of Packaging

Wooden Boxes

Wooden Pallet

Steel Box

Bundles

(Hexagonal or single tube)

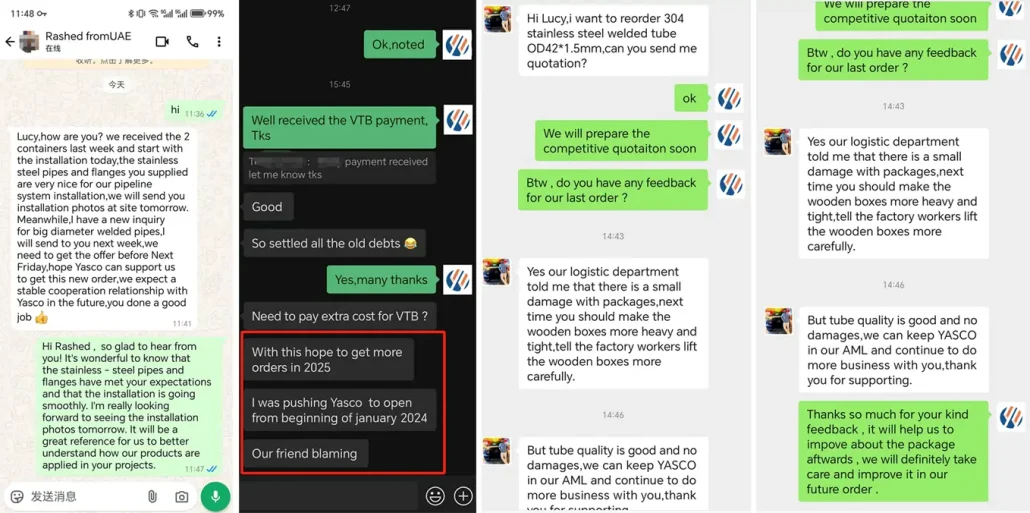

Customer’s Overview

Applications of 316L Stainless Steel Pipe

316 stainles steel pipe is Ideal for industries such as chemical processing, marine, oil and gas, and pharmaceuticals, 316 stainless steel pipes excel in high-temperature and high-pressure applications. Their durability, strength, and ease of fabrication make them a reliable choice for critical industrial operations.

Choose Yasco 316 stainless steel pipes for unmatched quality and long-lasting performance.

Ocean Platform

Chemical Industry Pipeline

Oil and Gas Industry

Fabrication of 316L Stainless Steel Pipe

Sometime we can also do some fabricaiton according to the drawing from the customer.

Attention

1.Avoid Chloride Exposure: While 316 stainless steel offers excellent corrosion resistance, prolonged exposure to high concentrations of chlorides (e.g., seawater or salt solutions) can cause pitting or crevice corrosion. Ensure proper material selection for such environments.

2.Avoid Galvanic Corrosion: When connecting 316 pipes with dissimilar metals, ensure proper insulation to prevent galvanic corrosion caused by electrochemical reactions.

3.Welding Precautions: Use low-carbon 316L stainless steel filler materials during welding to prevent carbide precipitation and maintain corrosion resistance in welded areas.