Overview of 904L Stainless Steel Pipe

Yasco 904L stainless steel industrial pipes are designed for the most demanding applications, offering exceptional resistance to corrosion in aggressive environments.

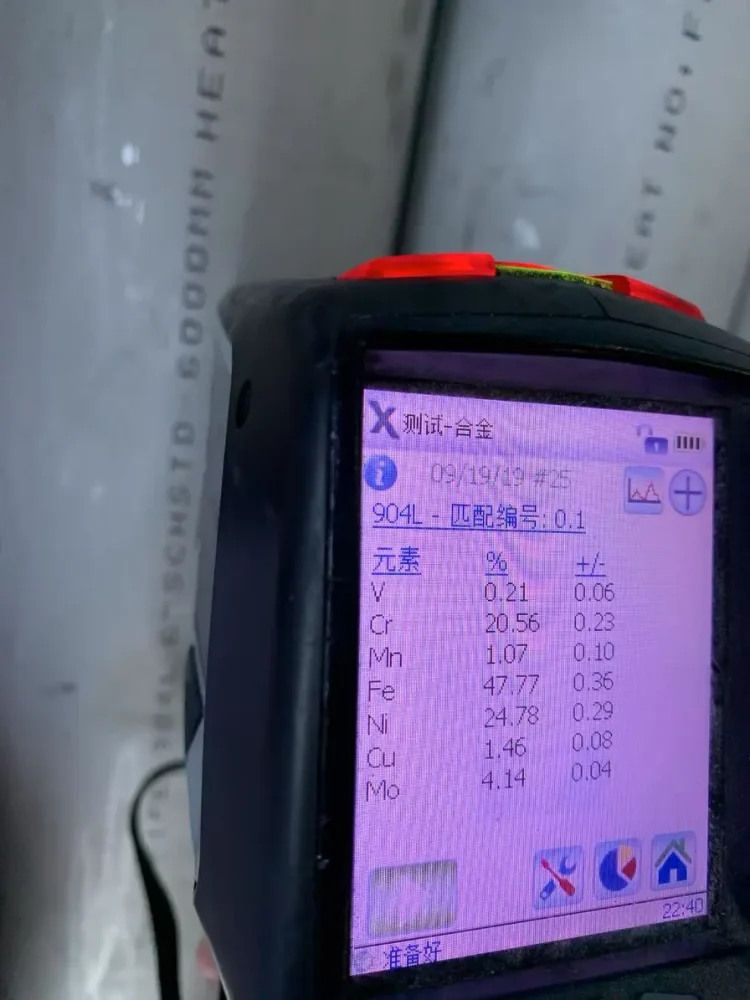

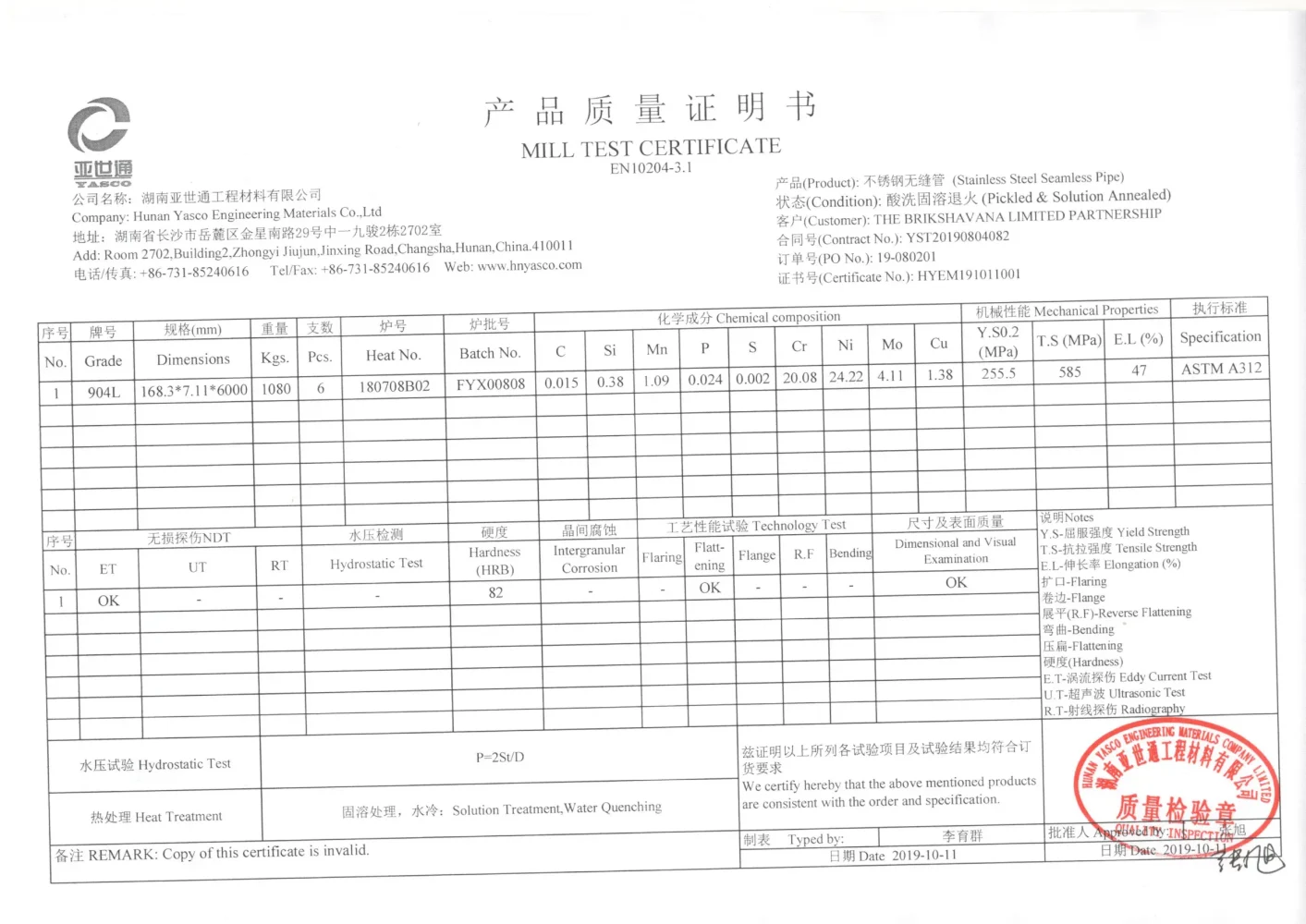

Made from a high-performance austenitic alloy containing chromium, nickel, molybdenum, and copper, 904L pipes excel in resisting sulfuric acid, phosphoric acid, and chloride-induced stress corrosion cracking.The main components are: Cr 18.0-20.0%、Ni 23.0-25.0%、Mo 3.0-4.0%、Cu 4.0-5.0%, Carbon content ≤ 0.03%.

Adding copper significantly enhances the corrosion resistance to reducing acids such as sulfuric acid and phosphoric acid.

Physical Performance and Corrosion Resistance

1.Tensile strength ≥ 490MPa, yield strength ≥ 216MPa, elongation ≥ 35%. Maintaining good toughness at low temperatures, suitable for use in environments ranging from -50 ℃ to 300 ℃.

It exhibits excellent corrosion resistance in dilute sulfuric acid (concentration ≤ 98%) and phosphoric acid (concentration ≤ 85%).Has strong resistance to chloride stress corrosion cracking and pitting corrosion.

Stainless Steel Pipe Specification Table

| Procedure | Stainless Steel Welded pipe |

| Dimensions | 10.3mm and up 1372 |

| 1/8″ and up 54″ | |

| DN6 and up DN1350 | |

| Thickness | 1.24mm and 60mm |

| SCH 5S ~SCH XXS | |

| Unit Length | As per standard or customized |

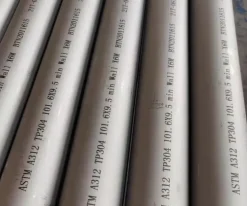

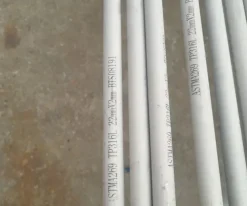

| Standards | ASTM A312, A358, A790, A249,A270…… |

| JIS G3463, G3448, JIS3468…… | |

| EN 10217-7, EN10312…… | |

| GB/T12771, HG20537, GB/T24539, GB/T19228, CJ/T151, HG20537.4…… | |

| DIN17457…… | |

| Surface | Pickling |

| Hairline | |

| Polish | |

| End Type | Plain, Bevelled, Threaded, Grooved |

| Joint Method | Fitting, Flange, Welding, Thread |

| Pipe Machining | Welding, Bending, Hole Drilling, Punching, Swaging, Tapering, Flaring, Expanding |

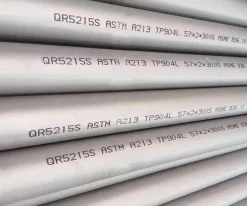

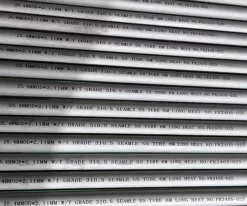

| Procedure | Stainless Steel Seamless Pipe |

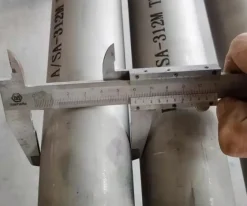

| Dimensions | 10.3mm and up 914 |

| 1/8″ and up 36″ | |

| DN6 and up DN900 | |

| Thickness | 1.24mm and 60mm |

| SCH 5S ~SCH XXS | |

| Unit Length | As per standard or customized |

| Standards | GB/T14975,GB/T14976,GB13296,GB5310…… |

| ASTM A312,A213,A269,A376,A511,A959,B677,ISO 15156-3…… | |

| DIN 17456,DIN 17458,EN10216-5…… | |

| JIS G3463,JIS G3459…… | |

| According to required specification is available. | |

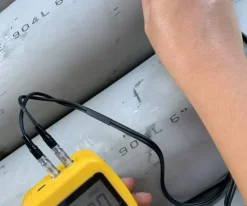

| Surface | Pickling |

| Sand Blast | |

| Polish | |

| End Type | Plain, Bevelled, Threaded, Grooved |

| Joint Method | Fitting, Flange, Welding,thread |

| Pipe Machining | Welding, Bending, Hole Drilling, Punching, Swaging, Tapering, Flaring, Expanding |

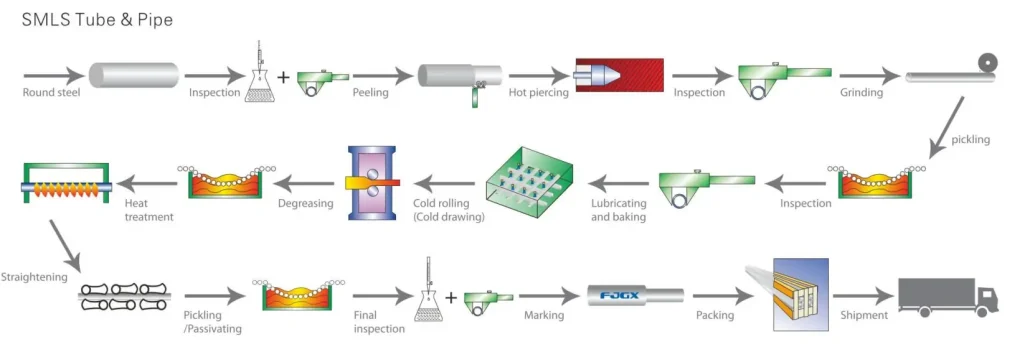

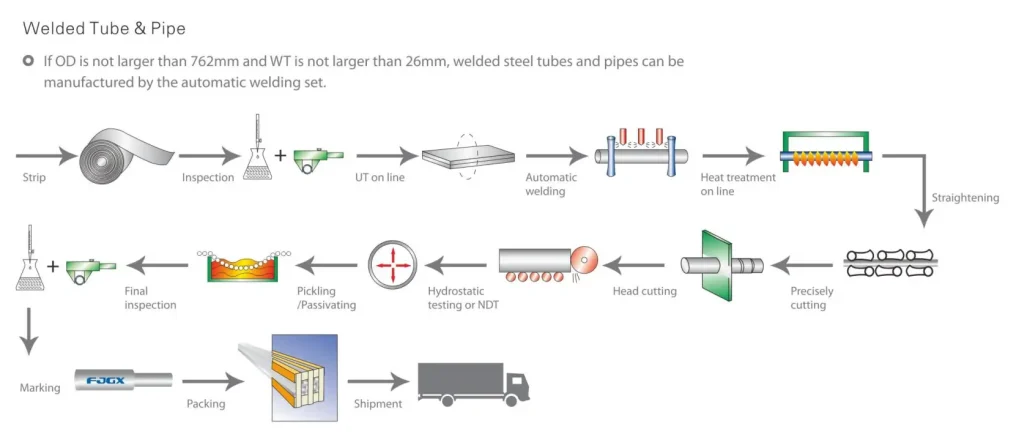

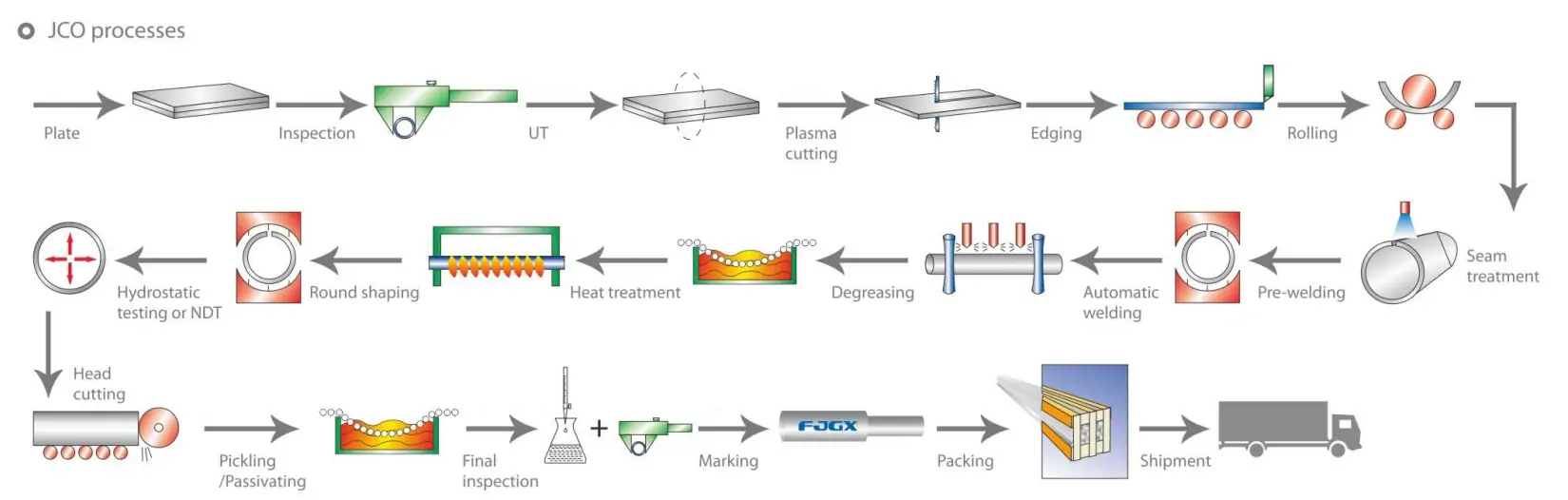

Manufacturing Processing

Application

Yasco 904L stainless steel pipe is widely used for industries such as chemical processing, oil and gas, and seawater desalination, these pipes provide superior durability and longevity. With excellent weldability and formability, 904L stainless steel pipes are the perfect choice for critical applications requiring unmatched reliability and performance. Choose our 904L pipes for superior quality and corrosion resistance.

Chemical reactor: It is used to manufacture all kinds of chemical reactors, which can withstand the erosion of many kinds of corrosive media such as sulfuric acid, phosphoric acid, acetic acid, formic acid and so on, to ensure the stability of the reaction process.

Petroleum refining equipment: In the process of oil refining, distillation tower, heat exchanger, reactor and other equipment will face high temperature, high pressure and corrosive media test, 904L stainless steel by virtue of its good heat resistance and corrosion resistance, can meet the use of these equipment requirements.

Submarine pipeline: Submarine pipeline conveying seawater, oil and gas and other media, 904L stainless steel has good seawater corrosion resistance and anti-stress corrosion cracking performance, to ensure the reliability of the submarine pipeline in the process of long-term use.

Types of Packaging

Wooden Boxes

Wooden Pallet

Steel Box

Bundles

(Hexagonal or single tube)

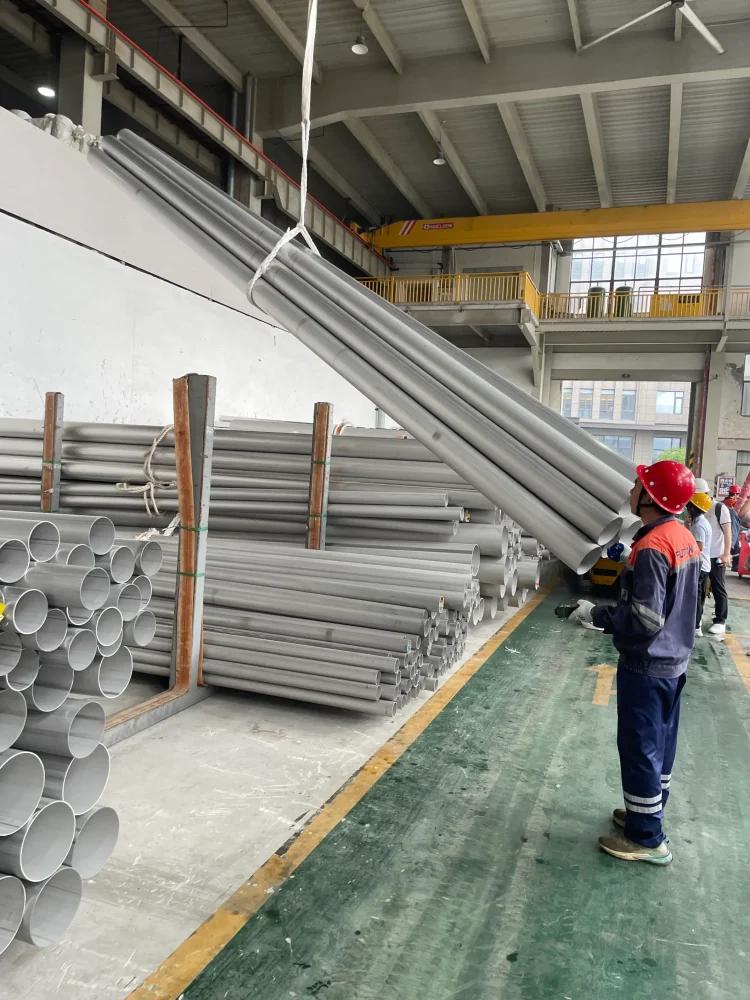

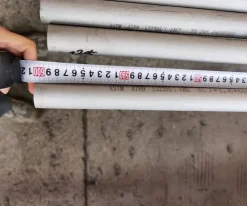

The Pipes in the Warehouse and Loading Pictures