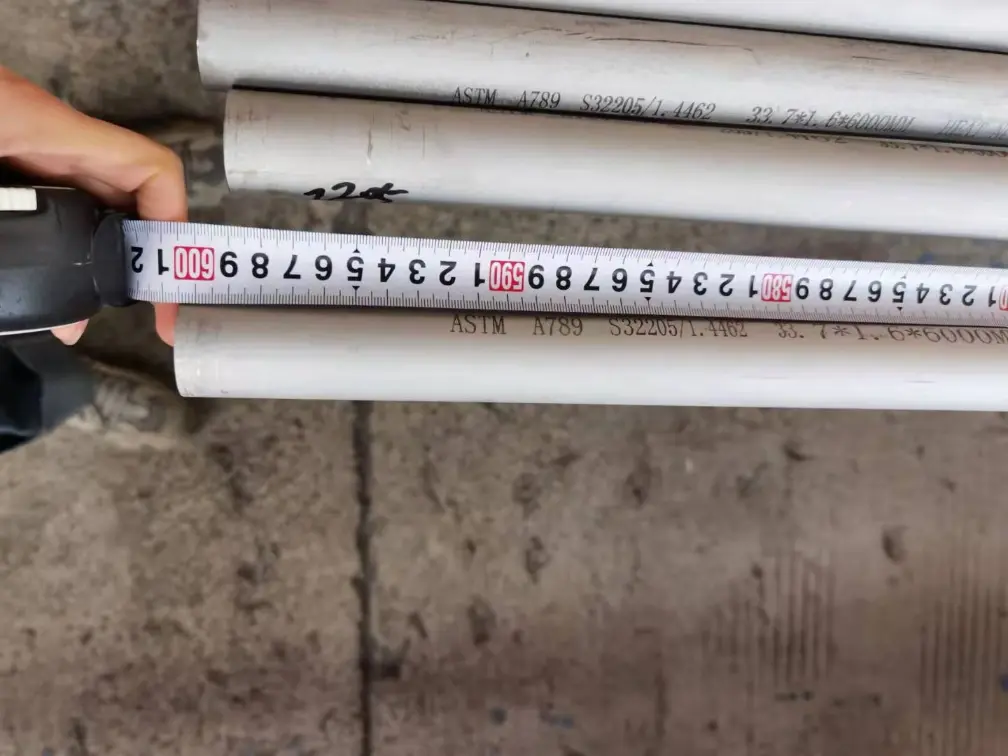

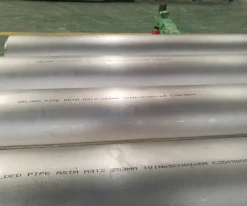

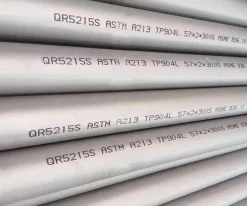

Overview of 2205 duplex pipe

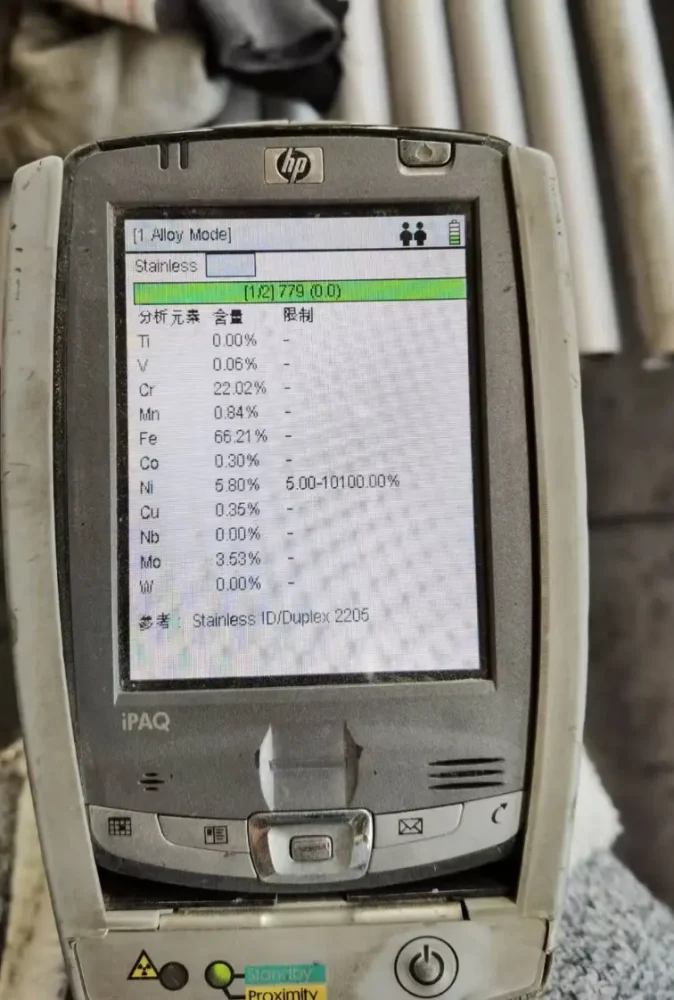

Yasco 2205 stainless steel pipe is a duplex stainless steel that combines the best features of austenitic and ferritic stainless steels. Its chemical composition typically includes:

Chromium (Cr): 22-23%,Nickel (Ni): 4.5-6.5%,Molybdenum (Mo): 3-3.5%,Manganese (Mn): 2% max,Silicon (Si): 1% max,Nitrogen (N): 0.14-0.20%,Carbon (C): 0.03% max,Phosphorus (P): 0.03% max,Sulfur (S): 0.02% max,Iron (Fe): Balance.

This unique composition provides 2205 stainless steel with exceptional strength, corrosion resistance, and durability.

Properties

Yasco 2205 stainless steel pipes offer a range of beneficial properties, making them a preferred choice in demanding environments:

High Strength: Approximately twice the strength of standard austenitic stainless steels, allowing for thinner and lighter designs.

Excellent Corrosion Resistance: Superior resistance to pitting, crevice corrosion, and stress corrosion cracking, especially in chloride-containing environments.

Good Weldability: Can be welded using common welding techniques without significant loss of corrosion resistance.

High Toughness: Maintains good impact strength even at low temperatures.

Fatigue Resistance: Exhibits excellent fatigue strength, making it suitable for dynamic load applications.

Cost-Effective: Offers a cost-effective solution due to its long service life and reduced maintenance requirements.

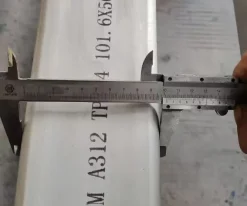

Stainless Steel Pipe Specification Table

| Procedure | Stainless Steel Welded pipe |

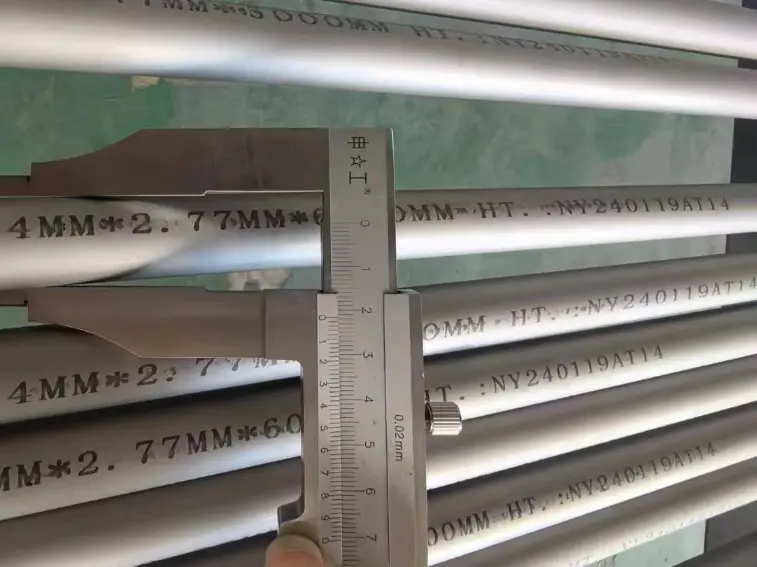

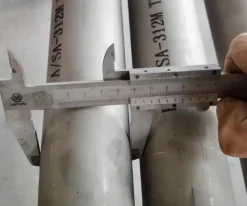

| Dimensions | 10.3mm and up 1372 |

| 1/8″ and up 54″ | |

| DN6 and up DN1350 | |

| Thickness | 1.24mm and 60mm |

| SCH 5S ~SCH XXS | |

| Unit Length | As per standard or customized |

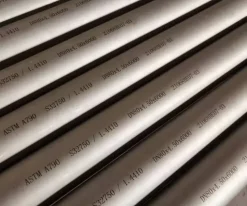

| Standards | ASTM A312, A358, A790, A249,A270…… |

| JIS G3463, G3448, JIS3468…… | |

| EN 10217-7, EN10312…… | |

| GB/T12771, HG20537, GB/T24539, GB/T19228, CJ/T151, HG20537.4…… | |

| DIN17457…… | |

| Surface | Pickling |

| Hairline | |

| Polish | |

| End Type | Plain, Bevelled, Threaded, Grooved |

| Joint Method | Fitting, Flange, Welding, Thread |

| Pipe Machining | Welding, Bending, Hole Drilling, Punching, Swaging, Tapering, Flaring, Expanding |

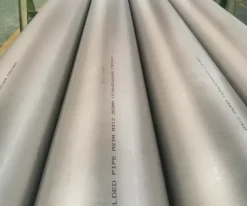

| Procedure | Stainless Steel Seamless Pipe |

| Dimensions | 10.3mm and up 914 |

| 1/8″ and up 36″ | |

| DN6 and up DN900 | |

| Thickness | 1.24mm and 60mm |

| SCH 5S ~SCH XXS | |

| Unit Length | As per standard or customized |

| Standards | GB/T14975,GB/T14976,GB13296,GB5310…… |

| ASTM A312,A213,A269,A376,A511,A959,B677,ISO 15156-3…… | |

| DIN 17456,DIN 17458,EN10216-5…… | |

| JIS G3463,JIS G3459…… | |

| According to required specification is available. | |

| Surface | Pickling |

| Sand Blast | |

| Polish | |

| End Type | Plain, Bevelled, Threaded, Grooved |

| Joint Method | Fitting, Flange, Welding,thread |

| Pipe Machining | Welding, Bending, Hole Drilling, Punching, Swaging, Tapering, Flaring, Expanding |

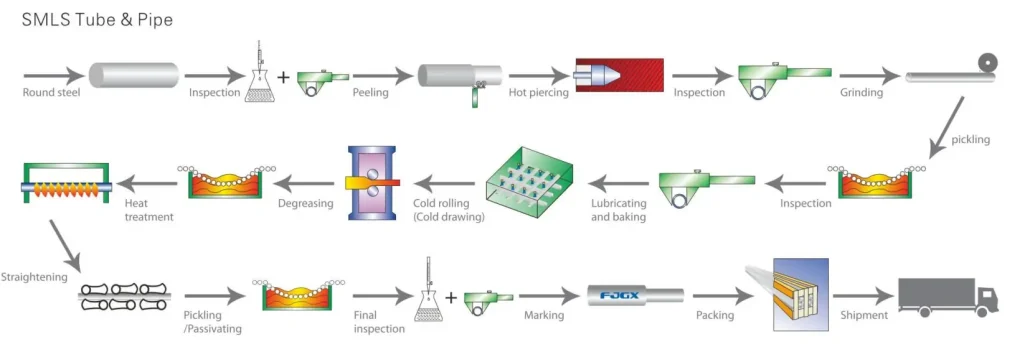

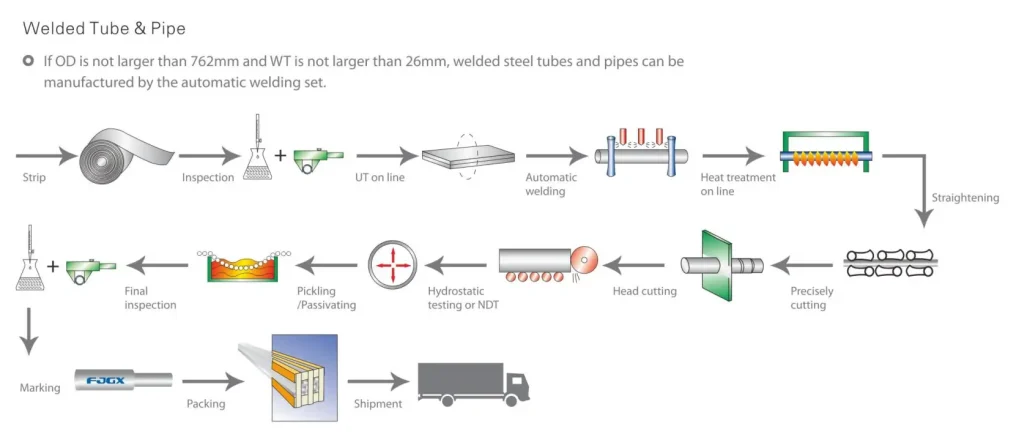

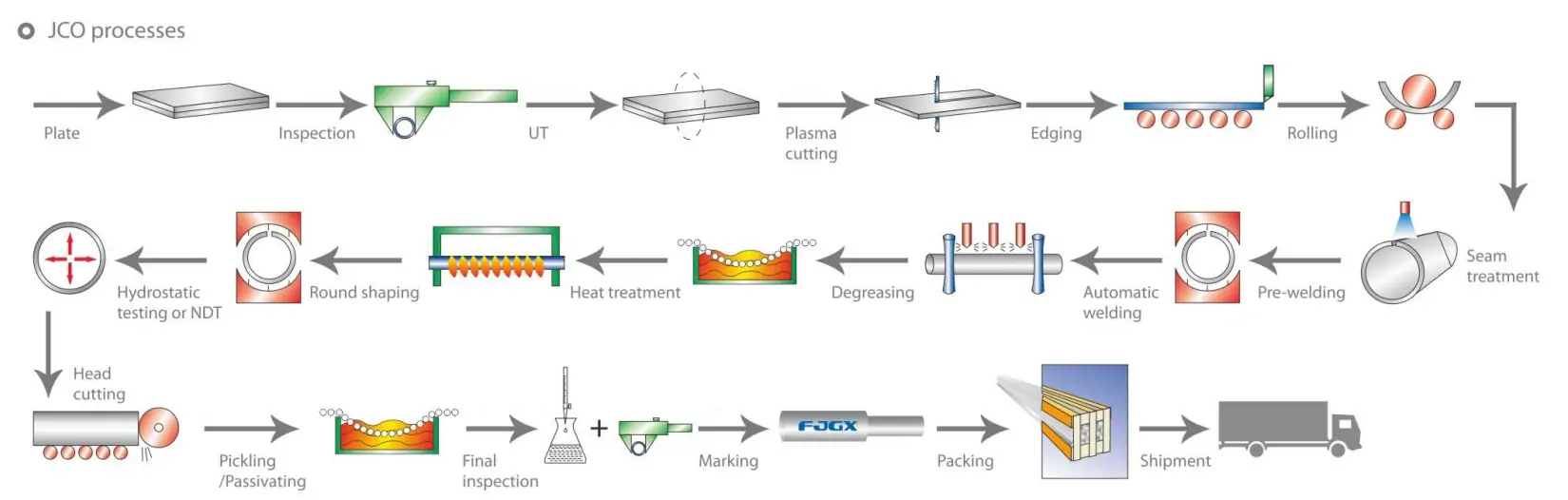

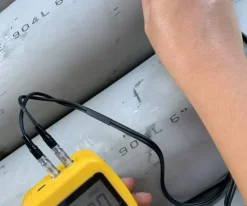

Manufacturing Processing

2507 Duplex Pipe: Temperature Limits, Processing, and Standards

Need to pay attention to below items, such as:

- Temperature limit: The long-term use temperature should be below 300 ° C to avoid a decrease in toughness.

- Processing control: to avoid work hardening, it is recommended to use low cutting speeds.

- The Standard specifications: We comply with international standards such as ASTM A240 and EN 1.4410.

If you want other standard we also can do, you can contact with us, our email is [email protected]. About the market price, it is influenced by specifications, processes and QTY, the details please contact us freely.

Pipeline Prefabrication Services

We can also do pipeline prefabrication processing, this is our prefabrication workshop.

Application of Duplex 2205 Pipe

2205 stainless steel pipes are widely used in various industries due to their excellent properties. Common applications include:

Oil and Gas Industry: Ideal for pipelines, offshore platforms, and subsea equipment due to high resistance to chloride stress corrosion cracking.

Chemical Processing: Suitable for handling corrosive chemicals and acids.

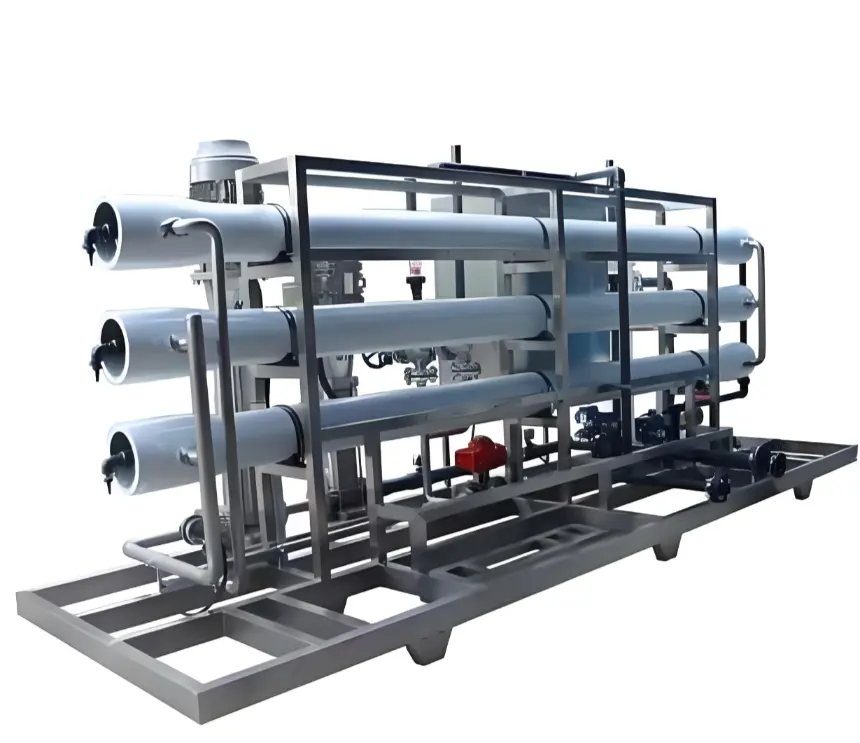

Desalination Plants: Used in seawater desalination processes because of its resistance to pitting and crevice corrosion.

Pulp and Paper Industry: Employed in equipment exposed to corrosive environments.

Pharmaceutical Industry: Utilized in the production of high-purity products requiring contamination-free environments.

Water Treatment: Applied in water purification systems and wastewater treatment plants.

Types of Packaging

Wooden Boxes

Wooden Pallet

Steel Box

Bundles

(Hexagonal or single tube)

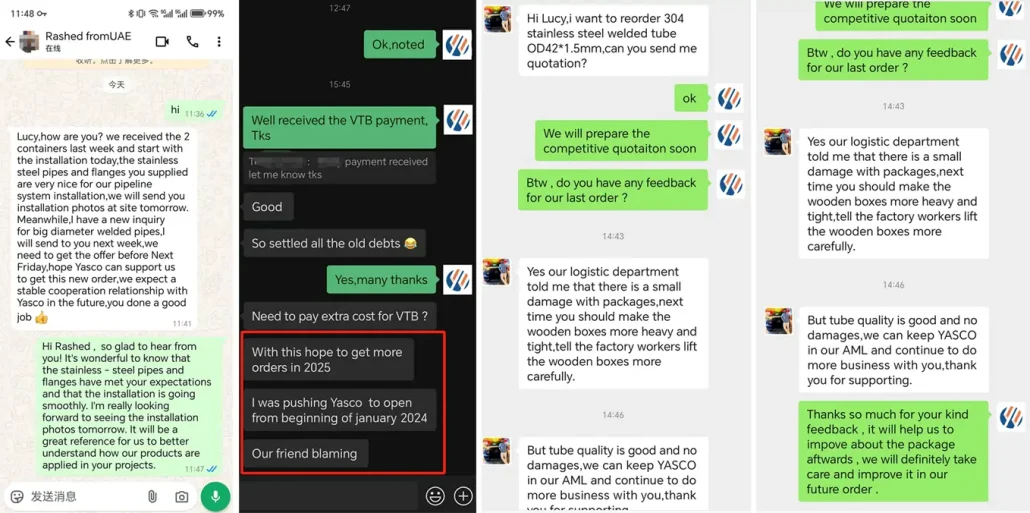

Customer’s Overview

Yasco Deplex 2205 Stainless Steel Pipes

2205 stainless steel pipes are a versatile and reliable choice for industries requiring high performance in corrosive and high-stress environments. Their unique composition, combined with exceptional mechanical and corrosion-resistant properties, ensures long-lasting durability and efficiency. Whether in the oil and gas sector, chemical processing, or water treatment, Yasco 2205 stainless steel pipes provide a robust solution to meet the most demanding industrial challenges.