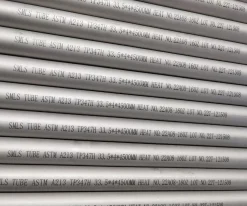

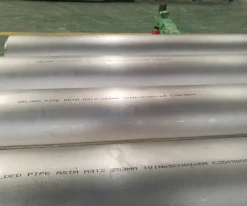

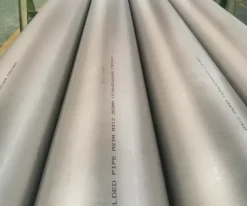

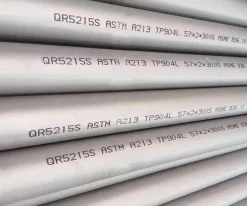

Introduction to Stainless Steel Thin-Wall Pipes

Yasco Stainless steel thin-wall pipes are a versatile and essential component in a wide range of industries due to their lightweight design, excellent corrosion resistance, and cost-effectiveness. These pipes are characterized by their thinner wall thickness compared to standard pipes, making them ideal for applications where weight reduction and material efficiency are critical. At Hunan yasco steel group we specialize in providing high-quality stainless steel thin-wall pipes that meet the diverse needs of our clients across various sectors.

What are Stainless Steel Thin-Wall Pipes?

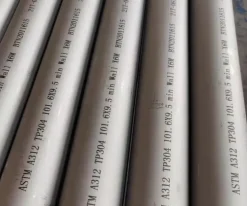

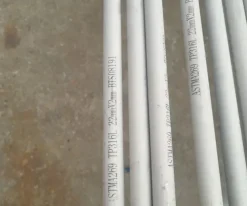

Yasco Stainless steel thin-wall pipes are made from high-quality stainless steel alloys, such as 304, 316, 310S, 904, 2205 ,3270 and duplex grades, with a reduced wall thickness. Despite their thinner walls, these pipes maintain excellent strength, durability, and resistance to corrosion, making them suitable for both industrial and commercial applications.

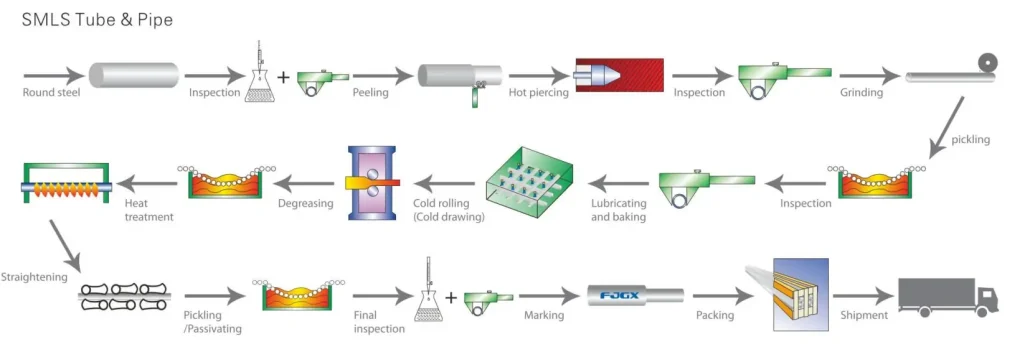

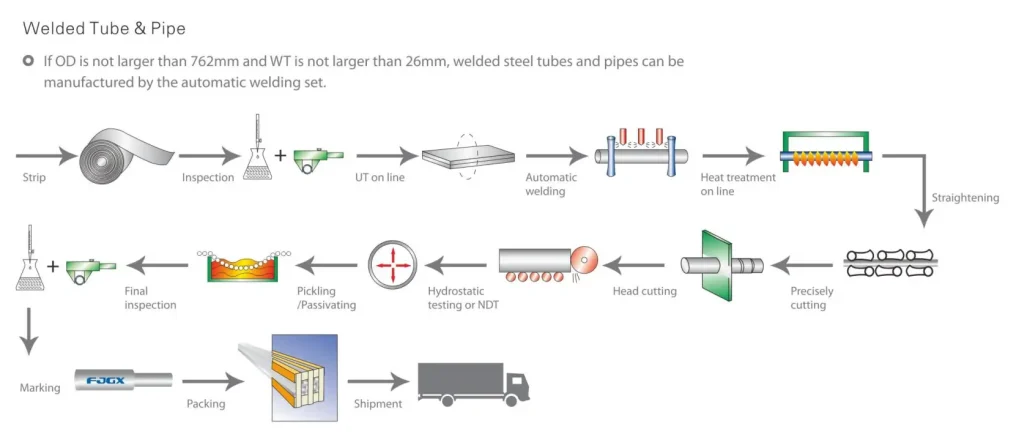

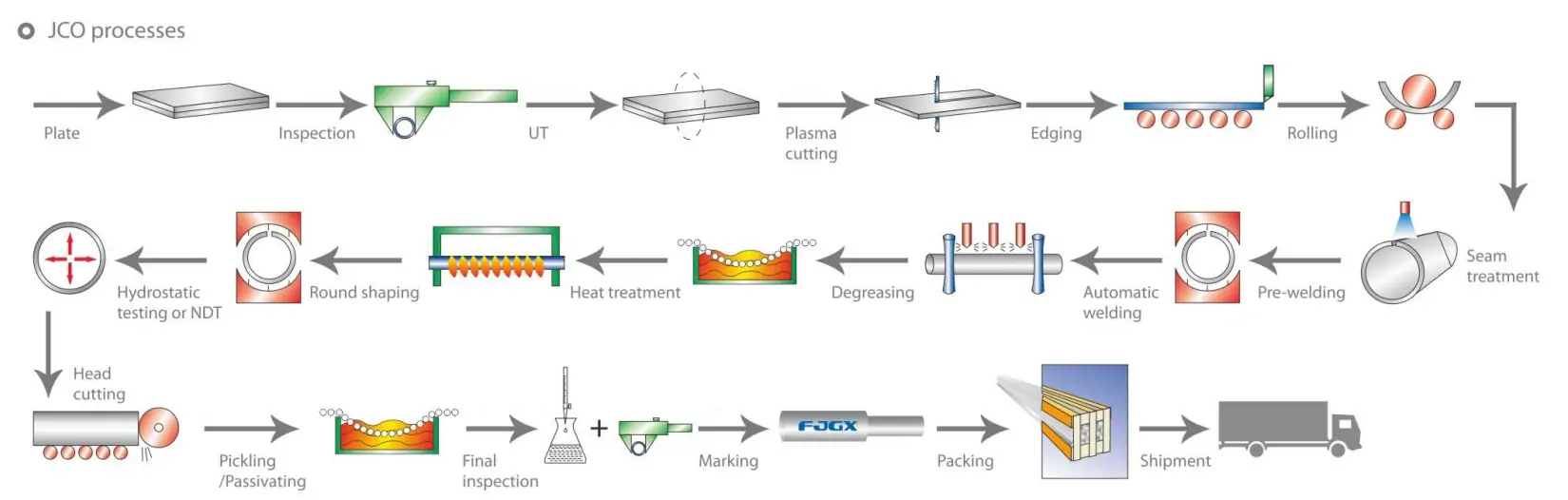

Manufacturing Processing

- Seamless super duplex pipe: manufactured through hot rolling, cold rolling, or cold drawing processes, suitable for high-pressure, high-precision scenarios.

- Welded super duplex pipe: using straight seam or spiral welding technology, mostly used for decoration and low-pressure pipeline systems.

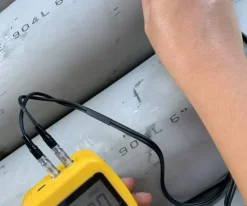

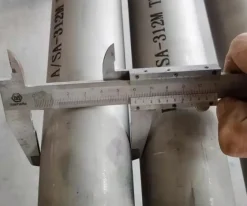

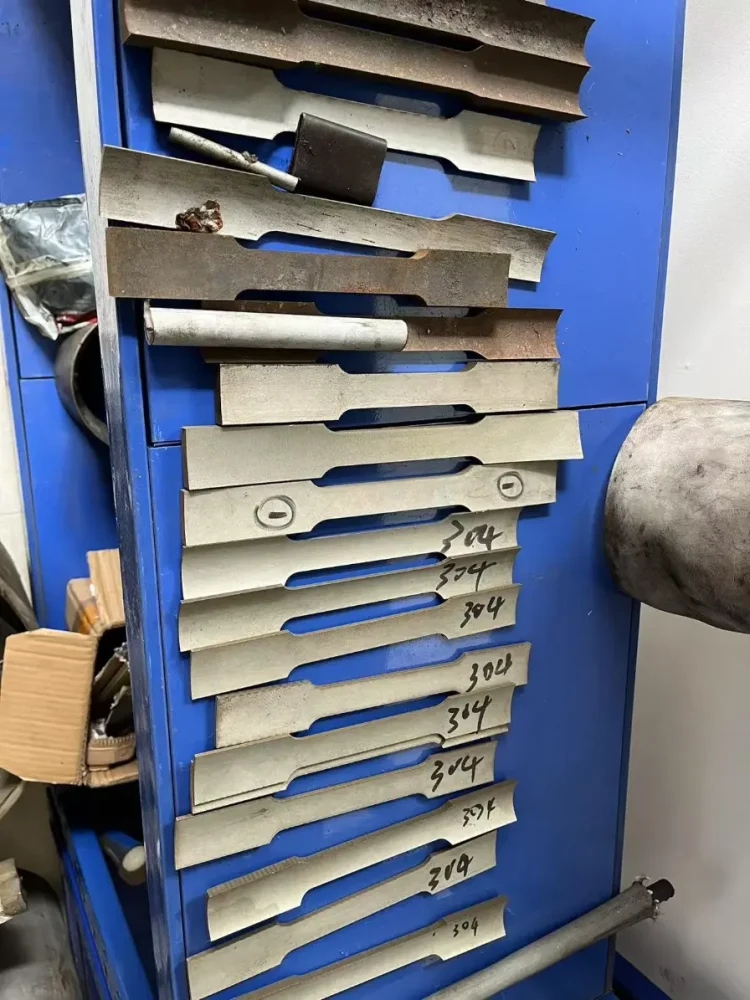

Quality Control :

Due to the relatively thin wall thickness, controlling the related physical properties can be challenging. Therefore, during production, we implement strict quality control measures and conduct comprehensive inspections to ensure the highest standards are met. Below are the common test for the thin wall stainless steel pipes

Tensile Testing according to the standard of ASTM E8/E8M or ISO 6892

Hydrostatic testing according to the standard of ASME B31.1/B31.3

Measure the thickness on the production site

Comparison with other materials

Compared with 254SMO stainless steel, 253MA has a lower nickel content, but achieves better high-temperature oxidation resistance and cost-effectiveness through high chromium, nitrogen, and rare earth elements; And 254SMO focuses on the corrosion resistance of extreme corrosive environments (such as seawater).

Specifications and standards

253MA stainless steel welded pipe product specifications: outer diameter of 10~1372mm(or more), wall thickness of 1.2~140mm(or more), customizable rectangular pipes and other irregular cross-sections;

Stainless Steel Pipe Specification Table

| Procedure | Stainless Steel Welded pipe |

| Dimensions | 10.3mm and up 1372 |

| 1/8″ and up 54″ | |

| DN6 and up DN1350 | |

| Thickness | 1.24mm and 60mm |

| SCH 5S ~SCH XXS | |

| Unit Length | As per standard or customized |

| Standards | ASTM A312, A358, A790, A249,A270…… |

| JIS G3463, G3448, JIS3468…… | |

| EN 10217-7, EN10312…… | |

| GB/T12771, HG20537, GB/T24539, GB/T19228, CJ/T151, HG20537.4…… | |

| DIN17457…… | |

| Surface | Pickling |

| Hairline | |

| Polish | |

| End Type | Plain, Bevelled, Threaded, Grooved |

| Joint Method | Fitting, Flange, Welding, Thread |

| Pipe Machining | Welding, Bending, Hole Drilling, Punching, Swaging, Tapering, Flaring, Expanding |

| Procedure | Stainless Steel Seamless Pipe |

| Dimensions | 10.3mm and up 914 |

| 1/8″ and up 36″ | |

| DN6 and up DN900 | |

| Thickness | 1.24mm and 60mm |

| SCH 5S ~SCH XXS | |

| Unit Length | As per standard or customized |

| Standards | GB/T14975,GB/T14976,GB13296,GB5310…… |

| ASTM A312,A213,A269,A376,A511,A959,B677,ISO 15156-3…… | |

| DIN 17456,DIN 17458,EN10216-5…… | |

| JIS G3463,JIS G3459…… | |

| According to required specification is available. | |

| Surface | Pickling |

| Sand Blast | |

| Polish | |

| End Type | Plain, Bevelled, Threaded, Grooved |

| Joint Method | Fitting, Flange, Welding,thread |

| Pipe Machining | Welding, Bending, Hole Drilling, Punching, Swaging, Tapering, Flaring, Expanding |

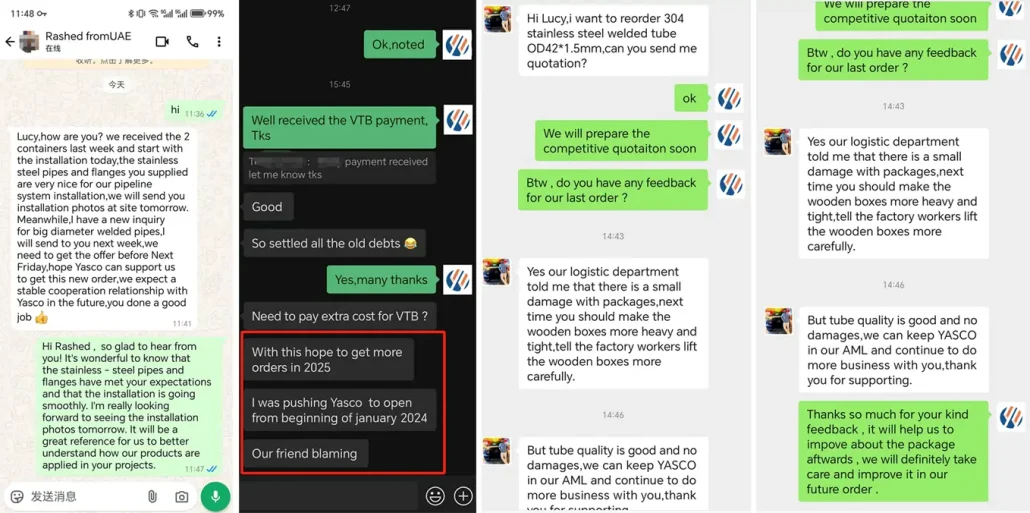

Types of Packaging

Wooden Boxes

Wooden Pallet

Steel Box

Bundles

(Hexagonal or single tube)