Stainless Steel Bent Tubes: Precision Engineering for Diverse Applications

At Hunan Yasco steel , we specialize in manufacturing high-quality stainless steel bent tubes tailored to meet the exacting demands of industries worldwide. With advanced technology and decades of expertise, we deliver solutions that combine durability, precision, and versatility.

What Are Stainless Steel Bent Tubes?

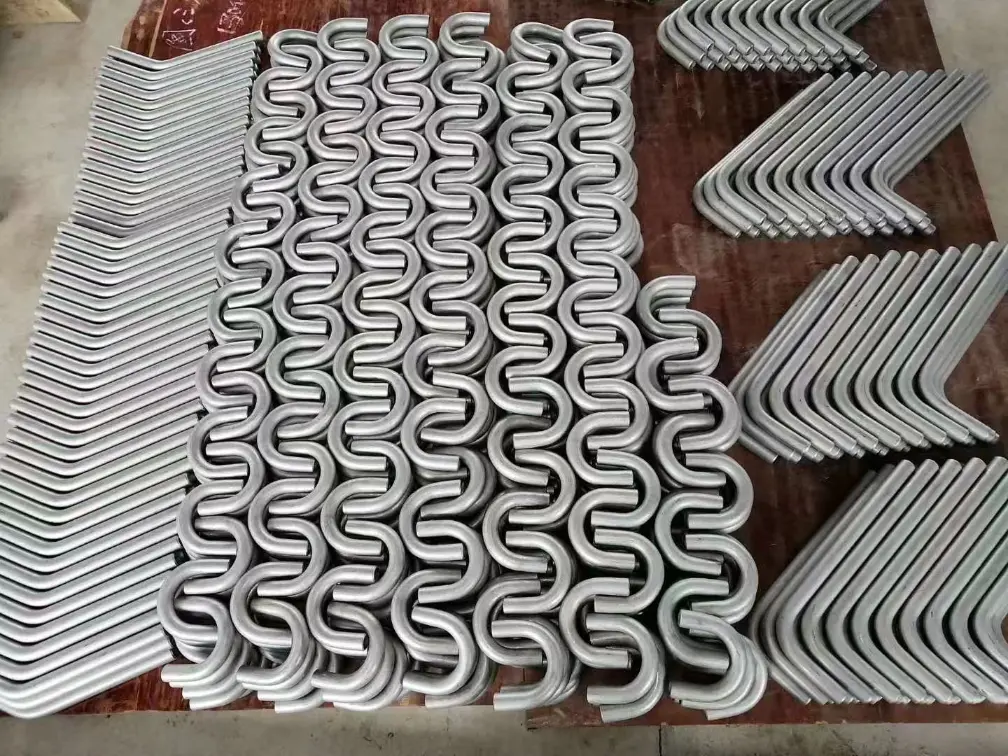

Stainless steel bent tubes are tubular components shaped into specific angles or curves (e.g., 45°, 90°, U-bends) without compromising structural integrity. They are fabricated using cold bending or hot bending techniques to ensure smooth surfaces, uniform wall thickness, and resistance to deformation.

Common Materials

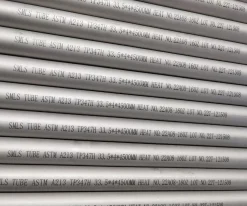

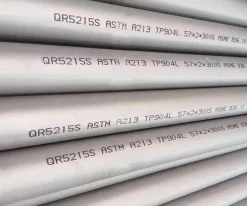

At Yasco ,We use premium stainless steel grades to ensure corrosion resistance, strength, and longevity:

304/304L: Ideal for general-purpose and food-grade applications.

316/316L: Superior chloride resistance for marine and chemical environments.

Duplex 2205: High strength for extreme pressure and temperature conditions.

Custom Alloys: Available upon request (e.g., 321, 310, 347H, 904L super duplex).

The Custom Fabrication Capabilities for stainless steel products of Yasco

- Advanced Bending Techniques

Cold Bending: For precise angles (15°–180°) with minimal ovality.

Hot Induction Bending: For thick-walled tubes and complex geometries.

Mandrel Bending: To prevent wrinkles and maintain inner diameter accuracy.

- Tailored Solutions

Bend Radius: From tight radii (1xD) to large sweeps (5xD).

Angles: Custom degrees (e.g., 30°, 60°, 180°) and multi-plane bends.

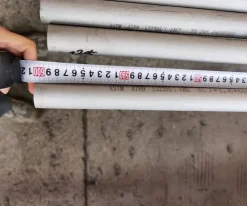

Sizes: Diameters from ¼” to 24″ (6mm to 600mm), wall thickness up to 50mm.

Surface Finish: Polished, brushed, or coated finishes to meet aesthetic or functional needs.

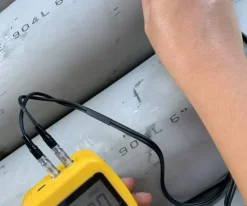

- Quality Assurance

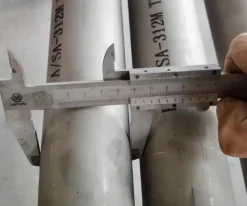

Laser Measurement: Ensures bend angle accuracy (±0.5° tolerance).

Non-Destructive Testing (NDT): Eddy current, hydrostatic, and X-ray inspection.

Certifications: Compliant with ASTM A312, DIN EN 10217-7, and ASME B16.49.

At Yasco , we go beyond standard stainless steel tubes and bent tubes to offer comprehensive deep processing solutions tailored for precision, durability, and complex industrial demands. Our state-of-the-art facilities and engineering expertise enable us to transform raw stainless steel into high-performance components that meet the most stringent specifications.

Forming & Fabrication

Stamping & Pressing: Hydraulic presses (up to 1,000 tons) shape stainless steel into housings, enclosures, and decorative panels.

Roll Forming: Produce cylindrical or conical structures (e.g., tanks, silos) with seamless curvature.

Deep Drawing: Create complex hollow shapes (e.g., sinks, containers) from sheets or plates.

Materials Supported: 304, 316, 430, duplex grades, and specialty alloys (e.g., 904L, 254SMO).

Welding & Joining

TIG/MIG Welding: Automated welding for leak-proof, corrosion-resistant joints in pipelines and pressure vessels.

Orbital Welding: For high-purity applications in pharmaceuticals, semiconductors, and food processing.

Cladding & Overlaying: Apply corrosion-resistant layers to carbon steel substrates for hybrid structures.

Whether you need standard bends or complex configurations, HunanYasco steel is your trusted partner for stainless steel bent tubes or any fabrication. We have strong technical support , can ollaborate with our engineers to fit your any project according to your project . Contact us to discuss your project requirements, we do believe our products and service will benefit your company .Reach us at any time by aurora@hnyasco.com

Types of Packaging

Wooden Boxes

Wooden Pallet

Steel Box

Bundles

(Hexagonal or single tube)

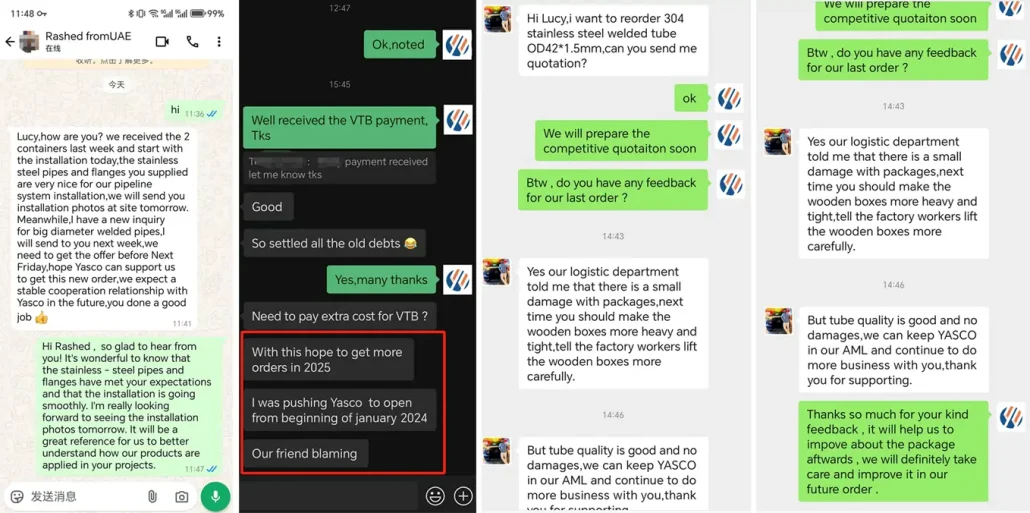

Customer’s Overview

Applications of Stainless Steel Bent Tube

316 stainles steel pipe is Ideal for industries such as chemical processing, marine, oil and gas, and pharmaceuticals, 316 stainless steel pipes excel in high-temperature and high-pressure applications. Their durability, strength, and ease of fabrication make them a reliable choice for critical industrial operations.

Choose Yasco 316 stainless steel pipes for unmatched quality and long-lasting performance.

Ocean Platform

Chemical Industry Pipeline

Oil and Gas Industry

Attention

1.Avoid Chloride Exposure: While 316 stainless steel offers excellent corrosion resistance, prolonged exposure to high concentrations of chlorides (e.g., seawater or salt solutions) can cause pitting or crevice corrosion. Ensure proper material selection for such environments.

2.Avoid Galvanic Corrosion: When connecting 316 pipes with dissimilar metals, ensure proper insulation to prevent galvanic corrosion caused by electrochemical reactions.

3.Welding Precautions: Use low-carbon 316L stainless steel filler materials during welding to prevent carbide precipitation and maintain corrosion resistance in welded areas.