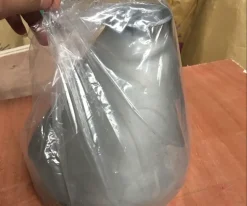

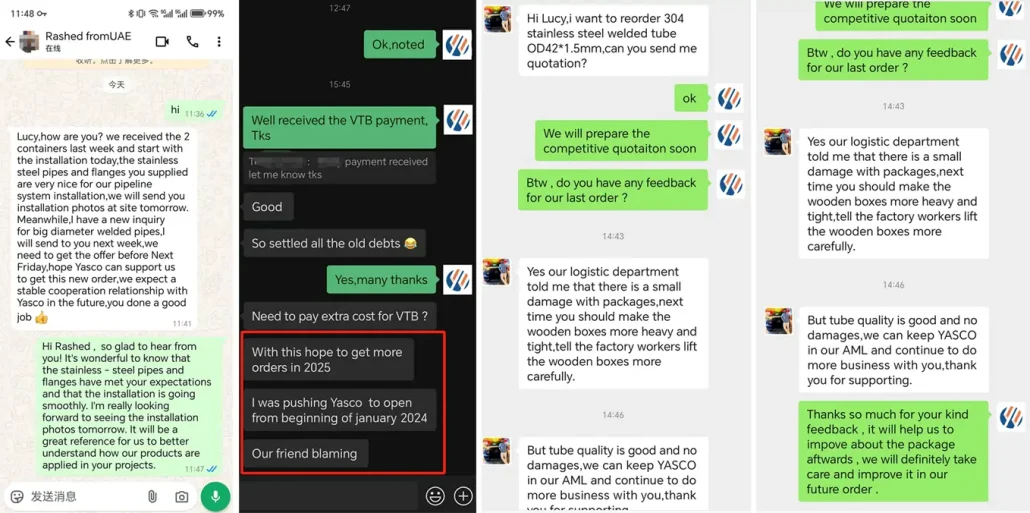

Overview of Stainless Steel Eccentric Reducer

Stainless steel eccentric reducer is a type of pipe fitting used to connect two pipes of different diameters while maintaining a flat surface on one side. Unlike a concentric reducer, which is symmetrical and aligned along the same center line, an eccentric reducer has one edge that is flat, allowing it to align with the bottom or top of the pipeline.

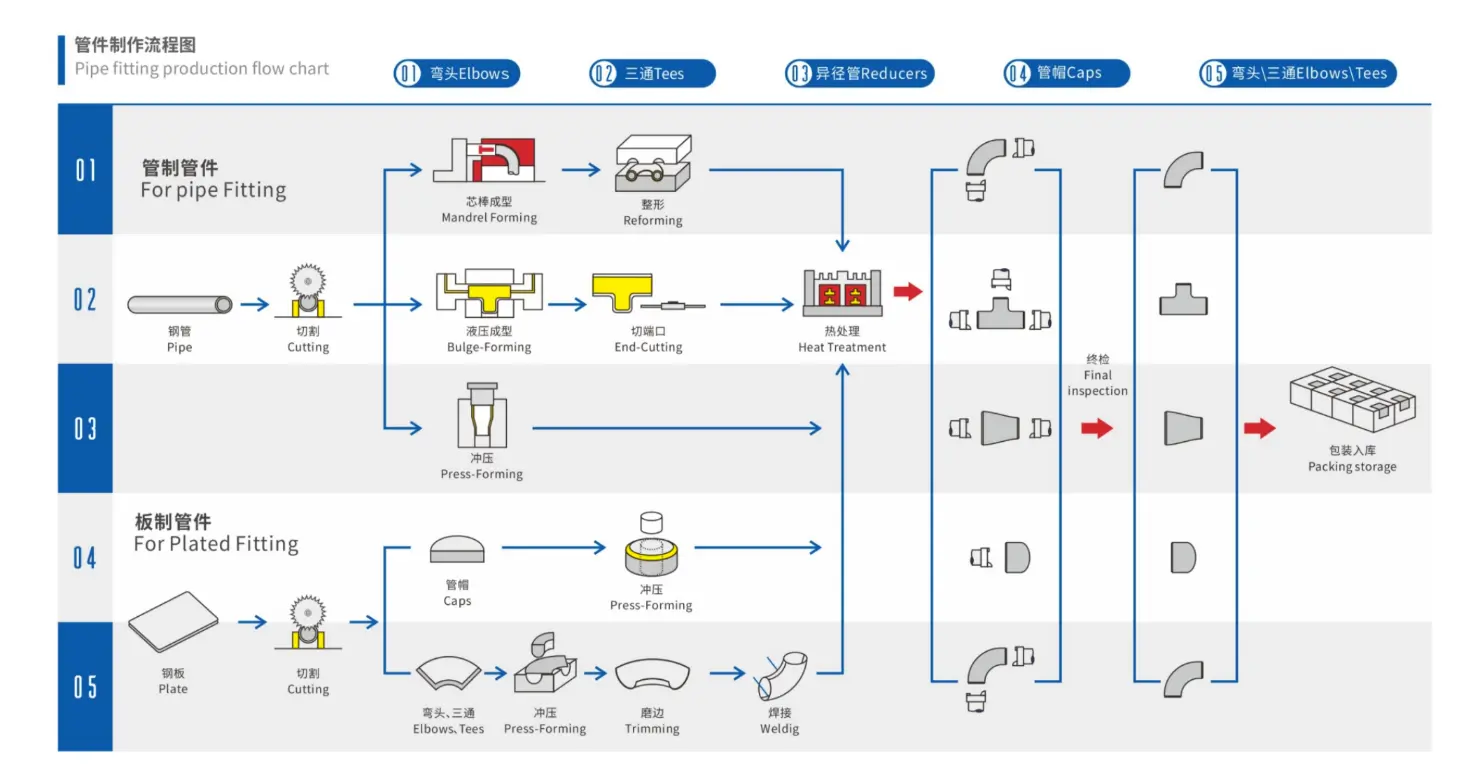

Manufacturing Processing of SS Fittings

In order to deliver the best products to customers, we select the raw materials from the beginning, strictly conduct the quality inspection, then cutting, forming, welding, heat treatment, surface finish, and finally conduct quality inspection on the finished products before packaging and delivery.

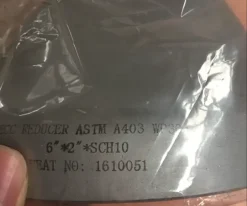

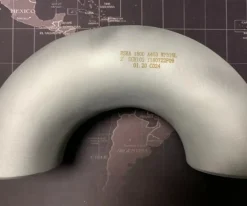

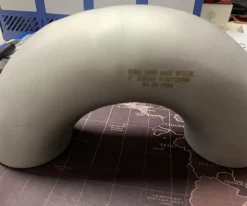

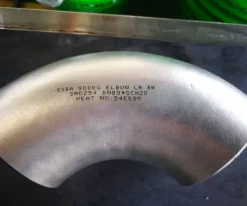

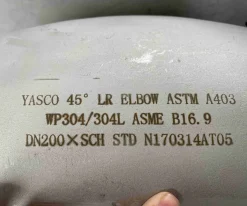

Specification of Stainless Steel Elbow

| NPS | Thickness | Material | Standard | Finish | End | ||

| DN15-DN3000

1/2"-120" |

Sch5s, Sch10s, Sch10, Sch20, Sch30, Sch40s, STD, Sch40, Sch80s, XS, Sch80, Sch100, Sch120, Sch140, Sch160, XXS |

Stainless steel | Duplex Steel | Alloy steel: | ASTM A403 ASTM A815 ASME/ANSI B16.9 DIN2605 MSS SP-43 |

Pickled,Sandblasting Beadblasting Mechanically Polished Bright Annealed Electro Polished |

Plain end Beveled end Threaded end |

| 31254, 904/L 347/H, 317/L 310S, 309 316Ti, 321/H 304/L, 304H 316/L, 316H |

UNS S31803, S32205, S32750, S32760 |

N04400, N08800 N08810, N08811 N08825, N08020 N08031, N06600 N06625, N08926 N08031, N10276 |

|||||

| Other requirements as per customers' design and drawings. | |||||||

Stainless Steel Reducer Workshop

Yasco has the facility equipped with machinery, tools, and skilled person to produce high-quality reducers (both concentric and eccentric) used in piping systems. The workshop is designed to handle various stages of production, from raw material processing to final inspection and packaging.