Yasco Stainless Steel Square Tubes: Precision Engineering for Structural Excellence

At Hunan Yasco steel group ,we deliver top-grade stainless steel square tubes designed to meet the demands of modern construction, industrial frameworks, and aesthetic applications. Renowned for their strength, corrosion resistance, and sleek geometry, our SS square tubes are engineered to provide unmatched performance and visual appeal. Below, we categorize our product range to help you select the ideal solution for your project.

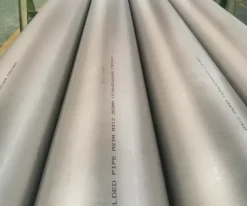

Stainless Steel Pipe Specification Table

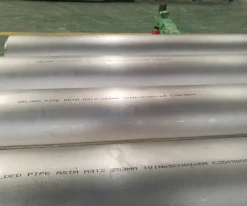

| Procedure | Stainless Steel Welded pipe |

| Dimensions | 10.3mm and up 1372 |

| 1/8″ and up 54″ | |

| DN6 and up DN1350 | |

| Thickness | 1.24mm and 60mm |

| SCH 5S ~SCH XXS | |

| Unit Length | As per standard or customized |

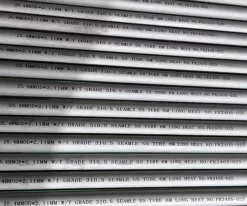

| Standards | ASTM A312, A358, A790, A249,A270…… |

| JIS G3463, G3448, JIS3468…… | |

| EN 10217-7, EN10312…… | |

| GB/T12771, HG20537, GB/T24539, GB/T19228, CJ/T151, HG20537.4…… | |

| DIN17457…… | |

| Surface | Pickling |

| Hairline | |

| Polish | |

| End Type | Plain, Bevelled, Threaded, Grooved |

| Joint Method | Fitting, Flange, Welding, Thread |

| Pipe Machining | Welding, Bending, Hole Drilling, Punching, Swaging, Tapering, Flaring, Expanding |

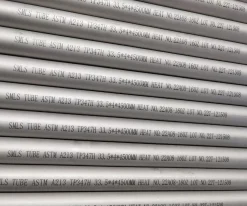

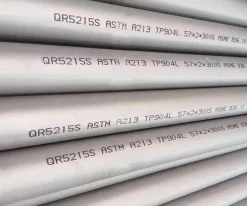

| Procedure | Stainless Steel Seamless Pipe |

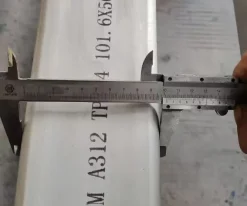

| Dimensions | 10.3mm and up 914 |

| 1/8″ and up 36″ | |

| DN6 and up DN900 | |

| Thickness | 1.24mm and 60mm |

| SCH 5S ~SCH XXS | |

| Unit Length | As per standard or customized |

| Standards | GB/T14975,GB/T14976,GB13296,GB5310…… |

| ASTM A312,A213,A269,A376,A511,A959,B677,ISO 15156-3…… | |

| DIN 17456,DIN 17458,EN10216-5…… | |

| JIS G3463,JIS G3459…… | |

| According to required specification is available. | |

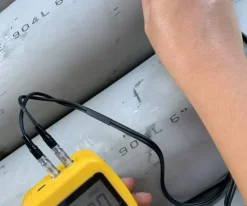

| Surface | Pickling |

| Sand Blast | |

| Polish | |

| End Type | Plain, Bevelled, Threaded, Grooved |

| Joint Method | Fitting, Flange, Welding,thread |

| Pipe Machining | Welding, Bending, Hole Drilling, Punching, Swaging, Tapering, Flaring, Expanding |

Material Grades of corrosion-resistant stainless steel square pipes

Yasco stainless steel square tubes are available in premium alloys to suit diverse environments:

304/304L: Versatile and cost-effective, ideal for architectural frameworks, railings, and indoor structures.

316/316L: Superior corrosion resistance for coastal areas, chemical plants, and outdoor installations.

201/202: Budget-friendly alternative with good formability, suitable for decorative and light-duty uses.

Duplex 2205: High strength and chloride resistance for offshore platforms, industrial equipment, and harsh environments.

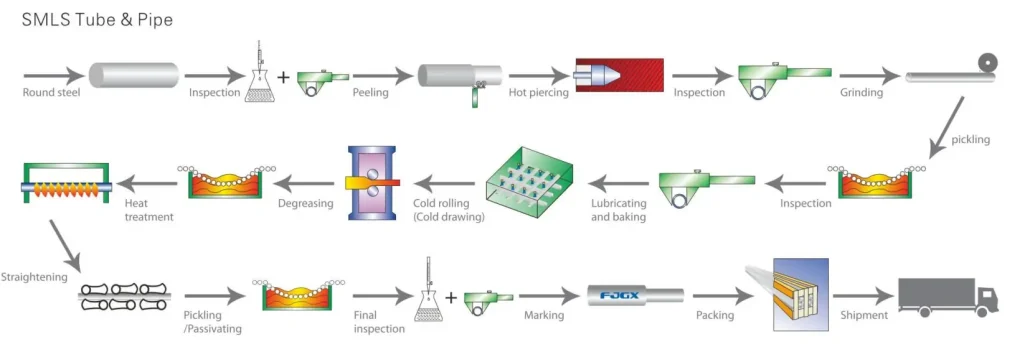

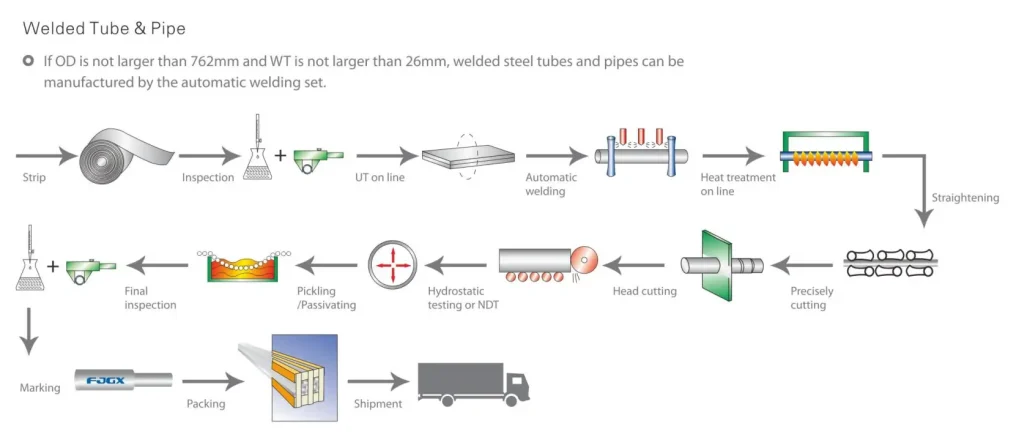

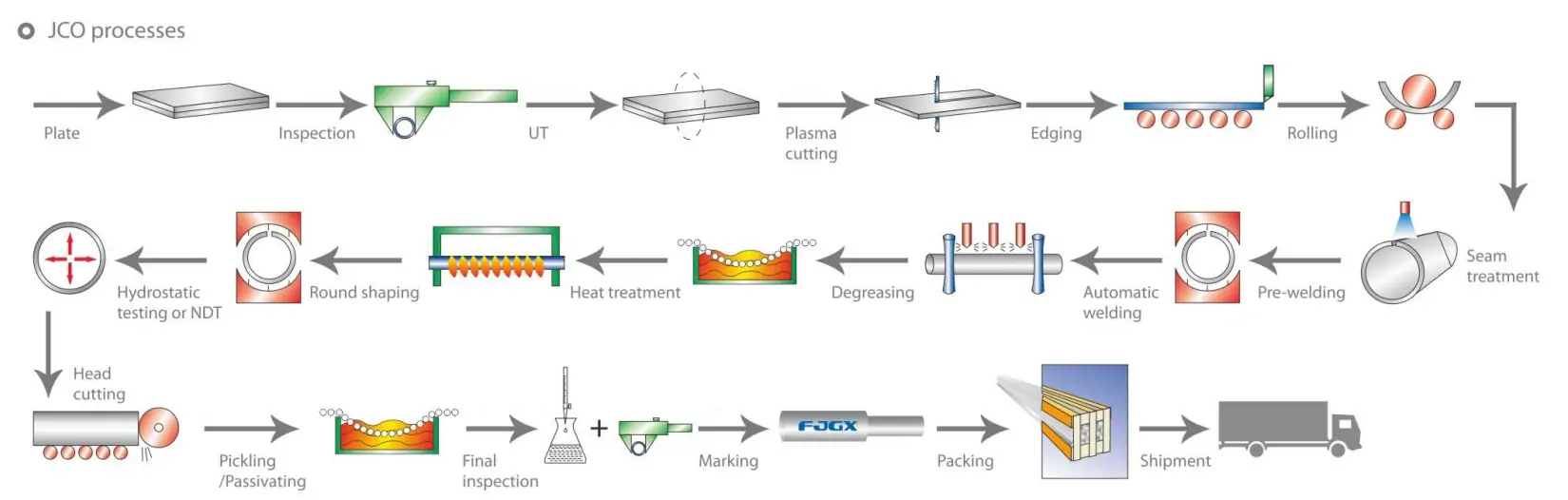

Manufacturing Processing

Welded stainless steel Square Tubes: Formed by cold-rolling and welding stainless steel coils, offering excellent dimensional accuracy for structural and decorative projects.

Seamless stainlesss teel square tubesOptions (Custom): Available upon request for specialized high-pressure or critical applications.

Applications of Stainless Steel Pipe

Stainless steel square tubes excel across industries:

Architecture & Construction: Staircases, canopy frames, glass balustrade supports, and modular buildings

Industrial Machinery: Conveyor systems, equipment guards, and robotic arm structures.

Transportation: Truck trailers, ship interiors, and automotive exhaust components.

Retail & Interior Design: Shelving units, display racks, and modern furniture.

Types of Packaging

Wooden Boxes

Wooden Pallet

Steel Box

Bundles

(Hexagonal or single tube)