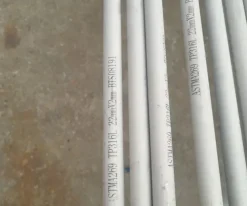

Introduction of Stainless Steel Seamless Pipes

Yasco Stainless Steel Seamless high pressure Pipes are tubular products manufactured from stainless steel alloys without any welded joints. They are crafted through a process that involves heating a solid cylindrical billet and piercing it to form a hollow tube, followed by elongation and finishing steps (e.g., hot rolling, cold drawing). This seamless construction ensures uniform strength, corrosion resistance, and reliability under high-pressure or extreme-temperature conditions.

Stainless Steel Pipe Specification Table

| Procedure | Stainless Steel Seamless Pipe |

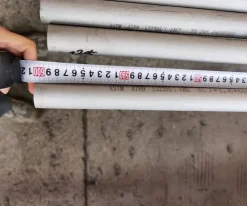

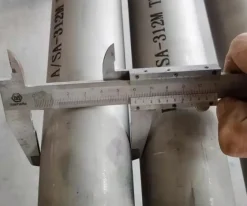

| Dimensions | 10.3mm and up 914 |

| 1/8″ and up 36″ | |

| DN6 and up DN900 | |

| Thickness | 1.24mm and 60mm |

| SCH 5S ~SCH XXS | |

| Unit Length | As per standard or customized |

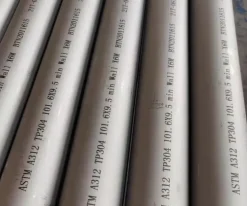

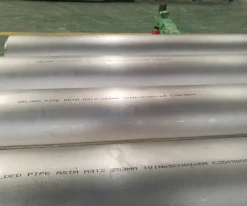

| Standards | GB/T14975,GB/T14976,GB13296,GB5310…… |

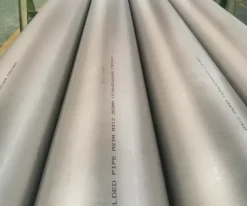

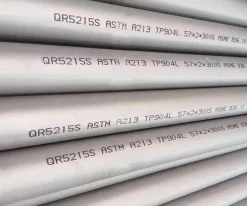

| ASTM A312,A213,A269,A376,A511,A959,B677,ISO 15156-3…… | |

| DIN 17456,DIN 17458,EN10216-5…… | |

| JIS G3463,JIS G3459…… | |

| According to required specification is available. | |

| Surface | Pickling |

| Sand Blast | |

| Polish | |

| End Type | Plain, Bevelled, Threaded, Grooved |

| Joint Method | Fitting, Flange, Welding,thread |

| Pipe Machining | Welding, Bending, Hole Drilling, Punching, Swaging, Tapering, Flaring, Expanding |

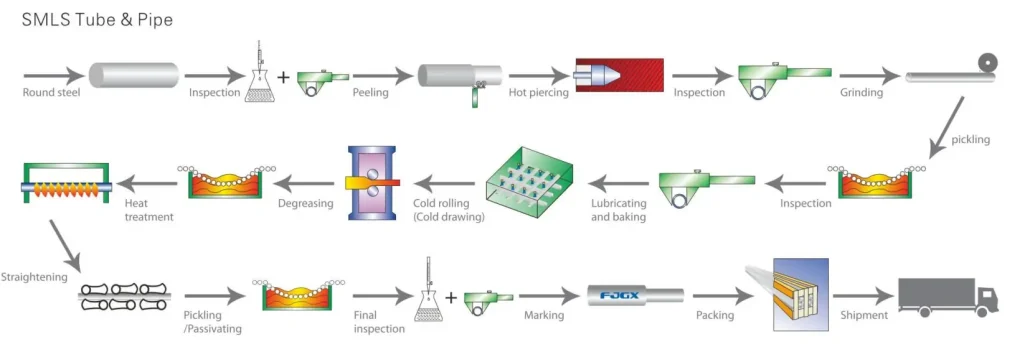

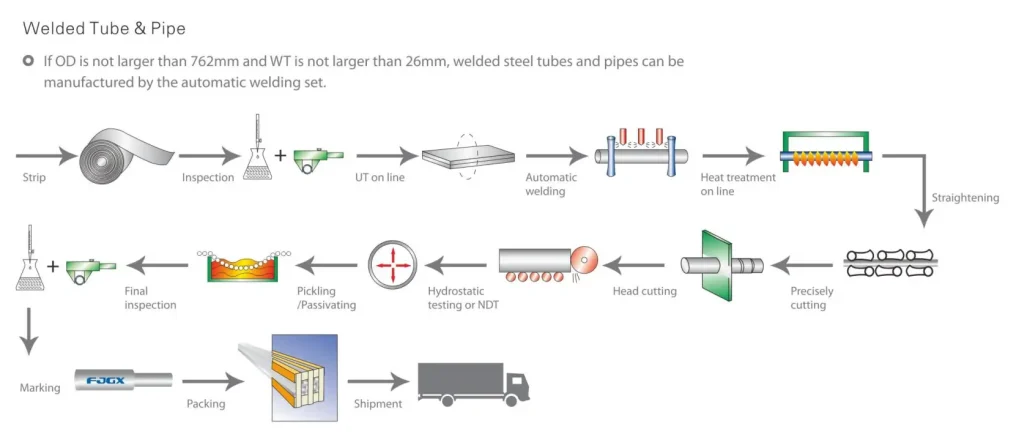

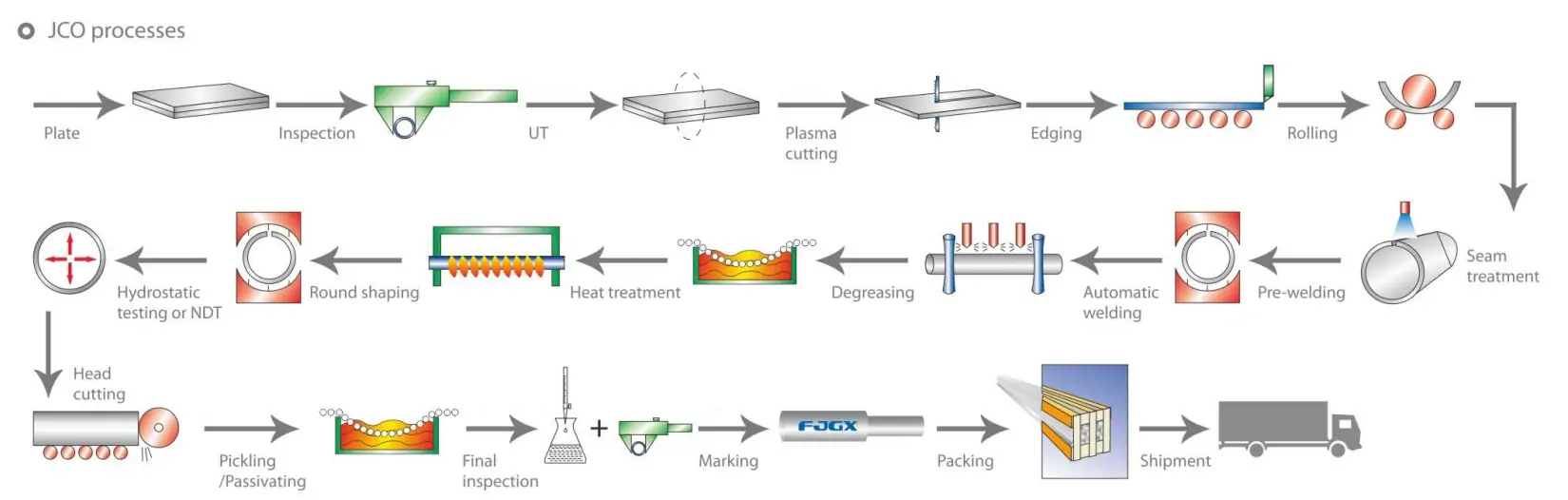

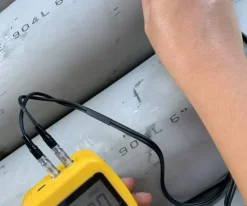

Manufacturing Processing

ASTM A312 stainless steel seamless tubes pipes : Available upon request for specialized high-pressure or critical applications.

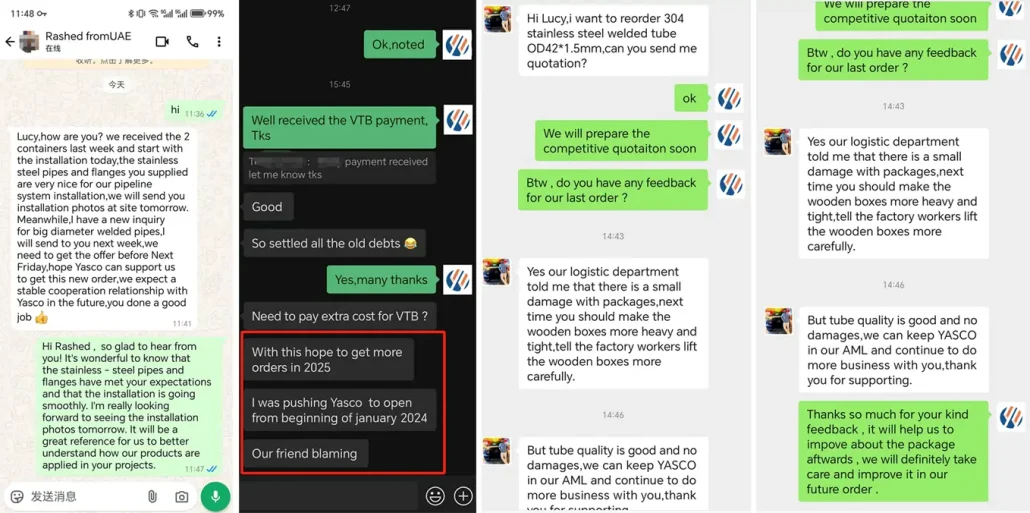

Why Choose Yasco stainless steel Seamless Pipes?

1. Superior Strength & Structural Integrity

Yasco Seamless stainless steel tubes are manufactured by extruding solid billets through a piercing rod, eliminating welded joints. This seamless construction ensures:

Uniform material distribution with no weak points, enhancing load-bearing capacity.

Higher pressure resistance, ideal for hydraulic systems, high-pressure pipelines, and aerospace components.

Reduced risk of failure under cyclic stress, critical for machinery and automotive parts.

2. Corrosion & Oxidation Resistance

Stainless steel (grades 304, 316, 321, etc.) contains chromium, nickel, and molybdenum, offering:

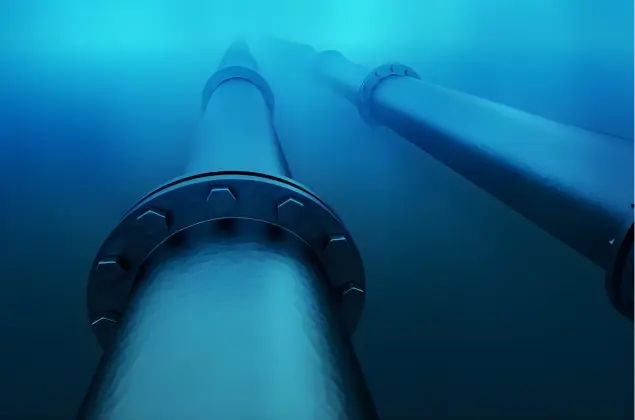

Long-term durability in harsh environments (e.g., seawater, acidic/alkaline chemicals, and high humidity).

Minimal maintenance costs compared to coated or carbon steel alternatives.

Non-reactive surfaces suitable for food processing, pharmaceuticals, and medical devices.

3. High-Temperature Performance

Seamless tubes retain mechanical stability at extreme temperatures:

Resist scaling up to 870°C (dependent on alloy composition).

Thermal expansion control for boilers, heat exchangers, and exhaust systems.

Fire-resistant properties, crucial for safety-critical applications.

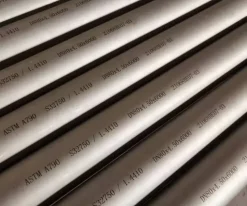

Material Grades of high pressure of stainless steel seamless pipes

Yasco stainless steel seamless pipe s are available in premium alloys to suit diverse environments:

304/304L: Versatile and cost-effective, ideal for architectural frameworks, railings, and indoor structures.

316/316L: Superior corrosion resistance for coastal areas, chemical plants, and outdoor installations.

201/202: Budget-friendly alternative with good formability, suitable for decorative and light-duty uses.

Duplex 2205: High strength and chloride resistance for offshore platforms, industrial equipment, and harsh environments.

And we have more choice like 310S, 321, 347H , 904L duplex like SS 32750 for your selection.

Application

Yasco stainless steel seamless pipes are trusted in critical sectors:

Oil & Gas: Downhole tubing, refinery pipelines, and LNG transport.

Power Generation: Boiler tubes, superheaters, and nuclear reactor components.

Chemical Processing: Reactors, heat exchangers, and corrosive fluid transfer.

Automotive: Fuel injection systems, turbochargers, and exhaust manifolds.

Types of Packaging

Wooden Boxes

Wooden Pallet

Steel Box

Bundles

(Hexagonal or single tube)