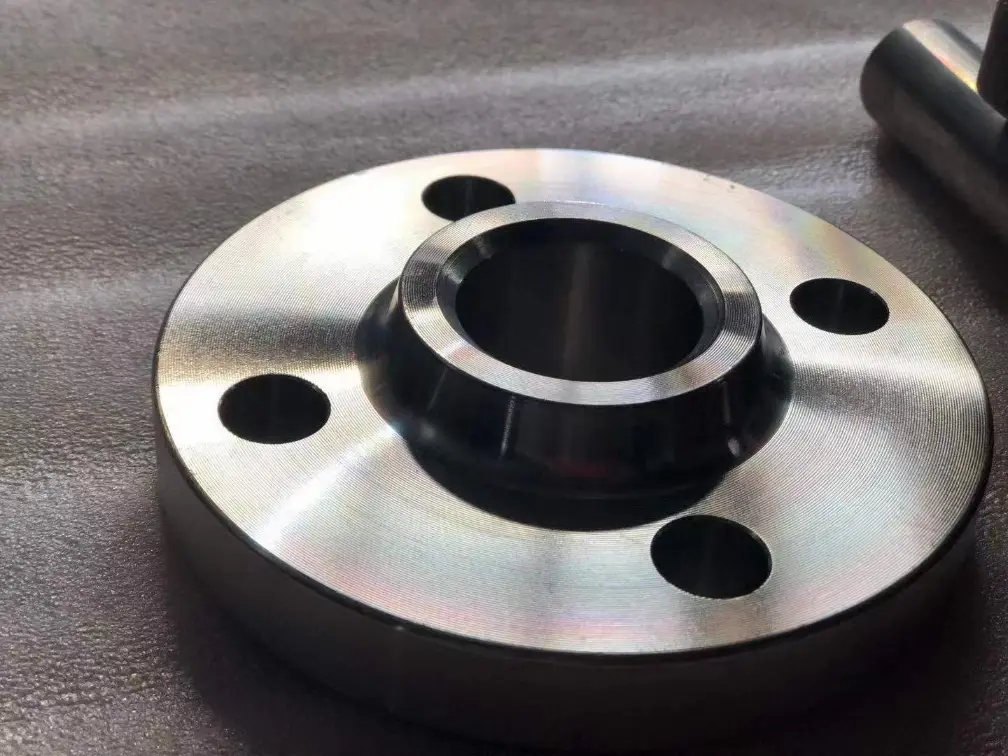

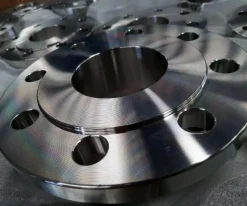

Overview of Stainless Steel Slip On Flange

A Stainless Steel Slip-On Flange is a type of pipe flange designed to easily slide over the end of a pipe and then be welded in place, both on the inside and outside, to provide a secure and leak-proof connection. It is characterized by its flat, circular shape with a slightly larger inner diameter than the pipe it is being attached to, allowing it to “slip on” effortlessly. The flange features bolt holes around its perimeter to align with matching flanges, enabling them to be bolted together with a gasket in between to create a tight seal.

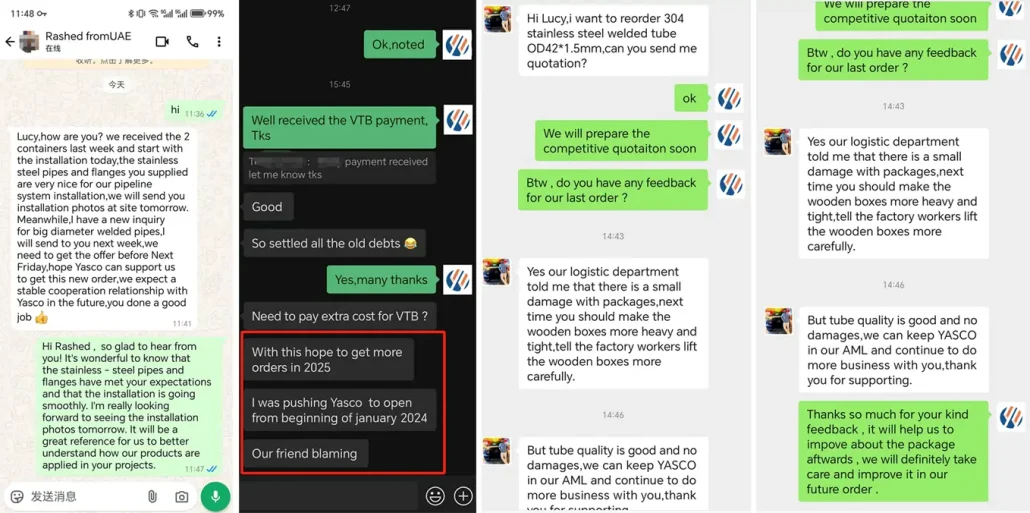

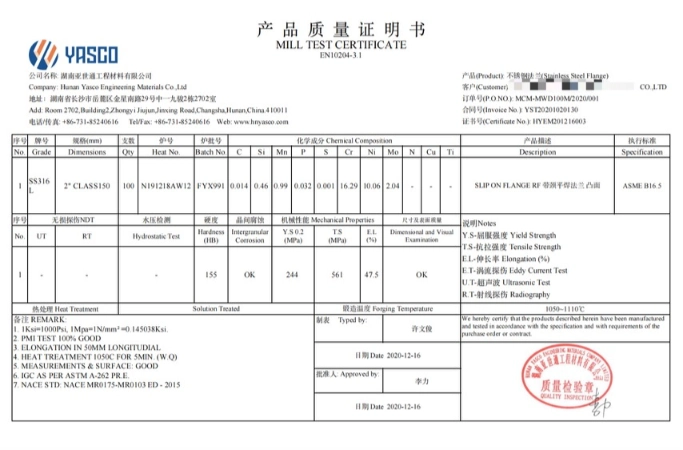

Stainless Steel Slip On Flange Mill Test Certificate

Stainless steel flange MTC is the official documents to confirm the quality,chemical composition,mechanical properties of stainless steel materials used to produce the flanges,we can guarantee that our products meets the standard and customers’ requirement.

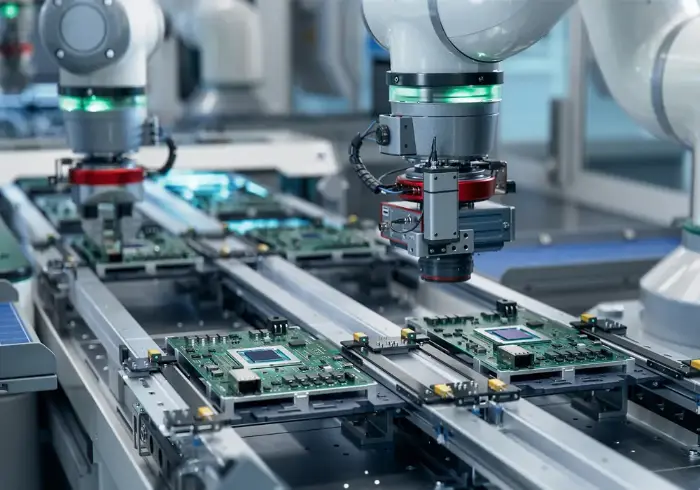

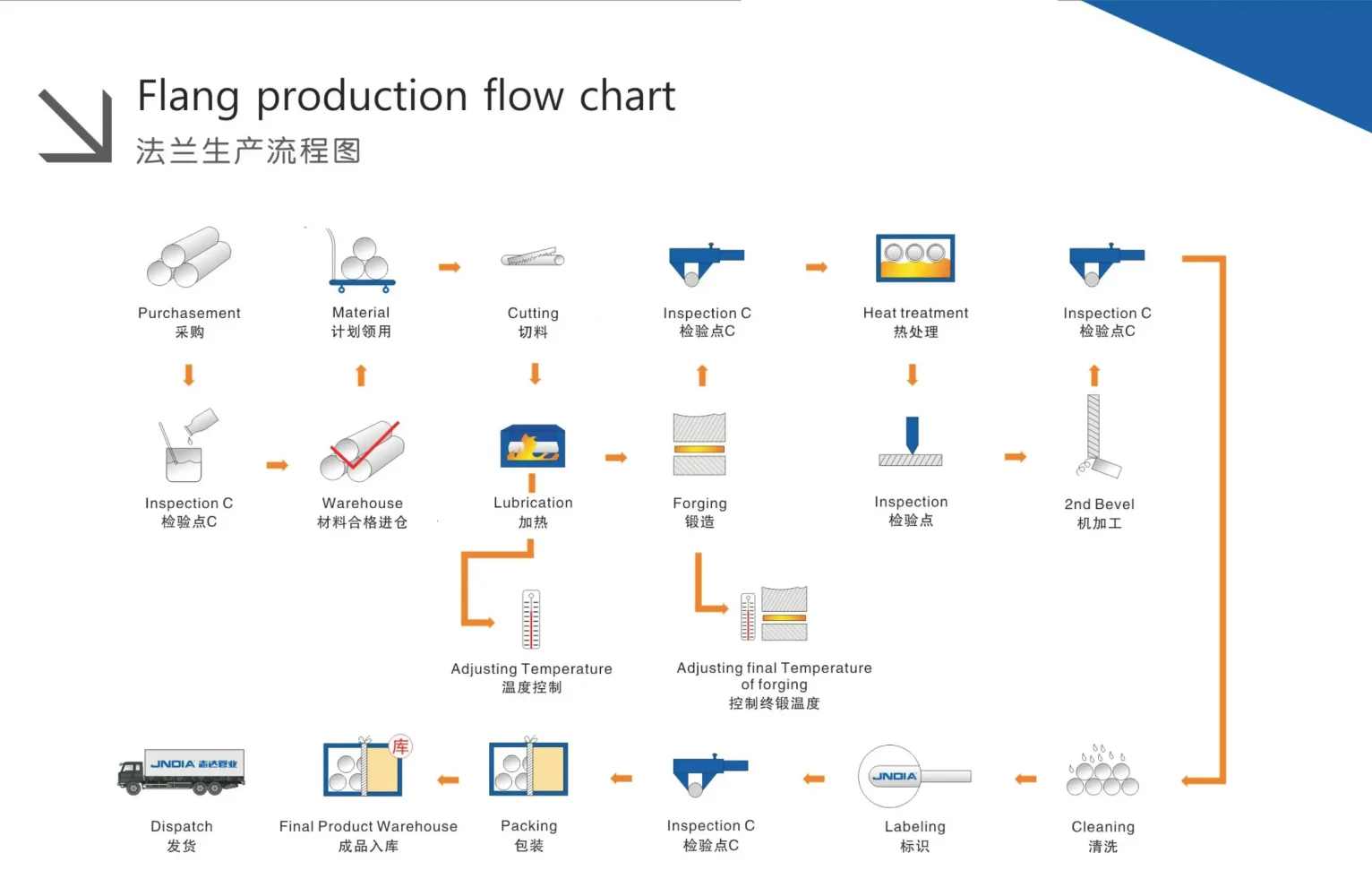

Manufacturing Processing

The manufacturing process of a stainless steel blind flange involves several steps to ensure the final product meets the required specifications and standards. Below is a detailed description of the process:

Specification of Stainless Steel Flange

| NPS | Pressure Rating | Material | Standard | Flange Face | |||

| DN15-DN3000 1/2"-120" | Class150- Class2500, PN10 - PN160 | Stainless steel | Duplex Steel | Alloy steel: | ASTM B16.5, ASTM B16.47, MSS SP44, EN1092-1, ASTM A182, JIS B2220, BS 4504, SABS/SANS1123, AWWA C207 | Ring Type Joint (RTJ), Flat Face (FF), Raised Face (RF) | |

| 31254, 904/L 347/H, 317/L 310S, 309 316Ti, 321/H 304/L, 304H 316/L, 316H | UNS S31803, S32205, S32750, S32760 | N04400, N08800 N08810, N08811 N08825, N08020 N08031, N06600 N06625, N08926 N08031, N10276 | |||||

| Other requirements as per customers' design and drawings. | |||||||

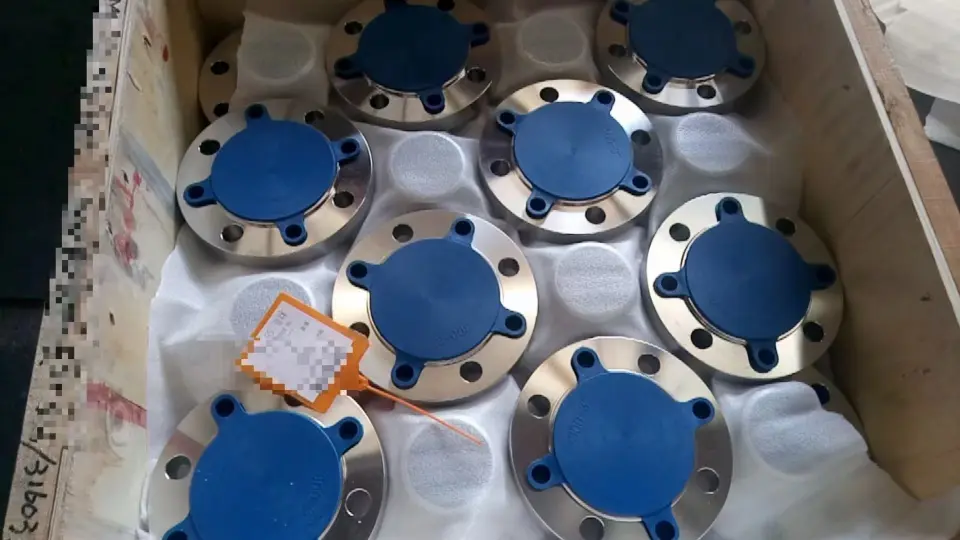

Type of packaging

– Wooden box for small diameter flanges

– Iron frame for large diameter flanges