Introduction to Yasco Super Duplex Pipe

Yasco Super Duplex pipes are a type of stainless steel pipe renowned for their exceptional strength, corrosion resistance, and durability. These pipes are made from Super Duplex stainless steel, a material that combines high levels of chromium, molybdenum, and nitrogen, resulting in a unique microstructure that offers superior performance in demanding environments.

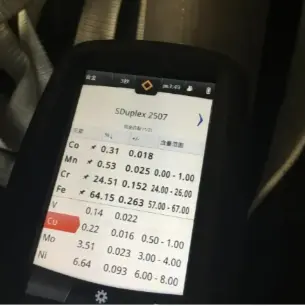

Super Duplex stainless steel typically contains:

Chromium (Cr): 24-26%,Nickel (Ni): 6-8%

Molybdenum (Mo): 3-4% , Nitrogen (N): 0.3-0.5%

This composition provides a balanced mix of austenitic and ferritic phases, which enhances the material’s mechanical properties and corrosion resistance. The high chromium and molybdenum content offer excellent resistance to pitting and crevice corrosion, while the nitrogen content increases strength and improves resistance to stress corrosion cracking.

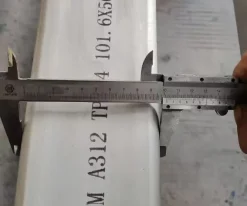

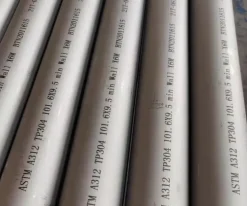

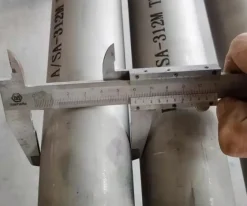

Stainless Steel Pipe Specification Table

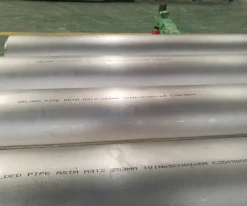

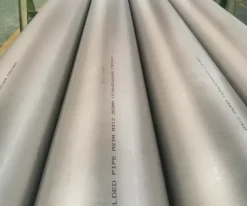

| Procedure | Stainless Steel Welded pipe |

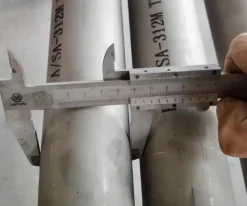

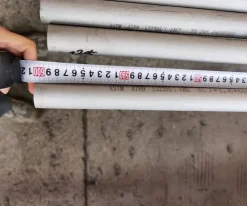

| Dimensions | 10.3mm and up 1372 |

| 1/8″ and up 54″ | |

| DN6 and up DN1350 | |

| Thickness | 1.24mm and 60mm |

| SCH 5S ~SCH XXS | |

| Unit Length | As per standard or customized |

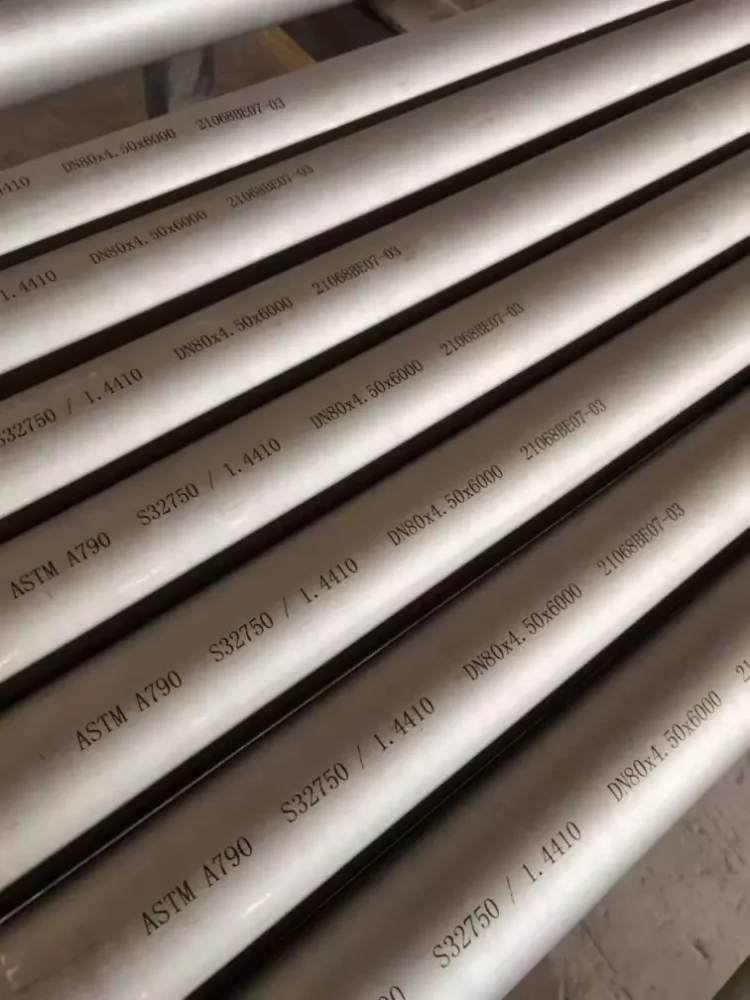

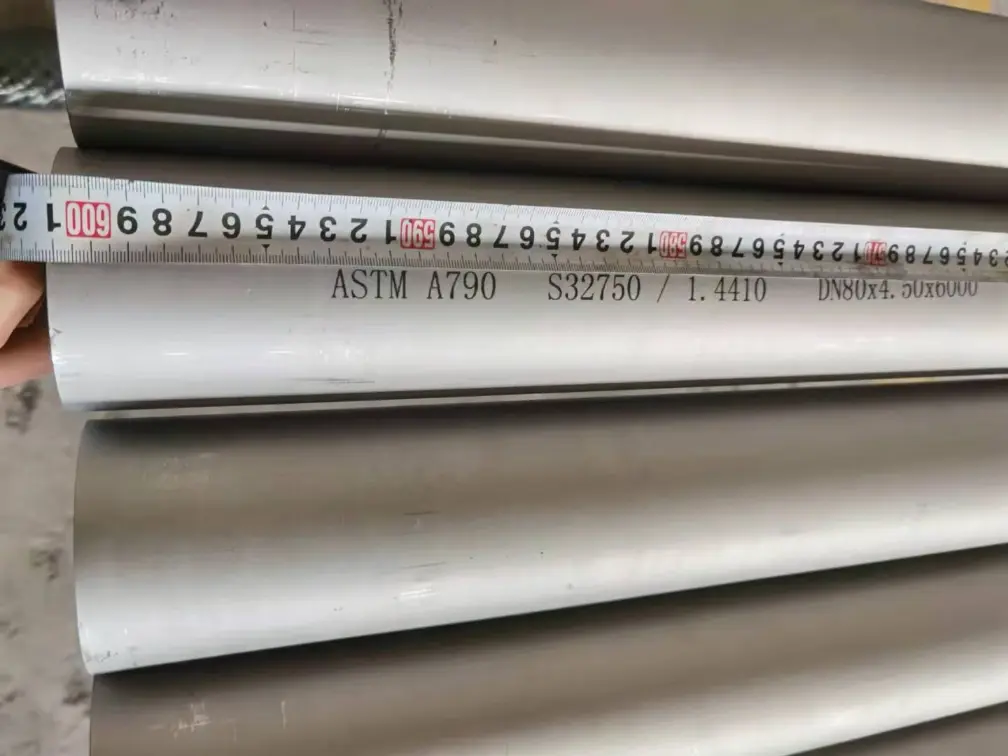

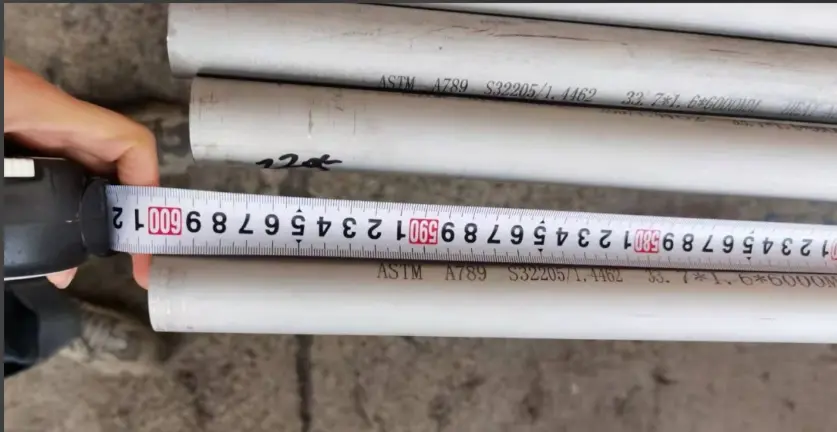

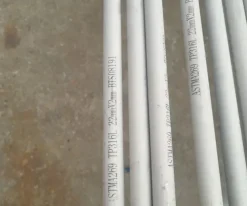

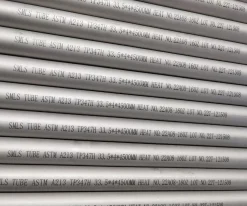

| Standards | ASTM A312, A358, A790, A249,A270…… |

| JIS G3463, G3448, JIS3468…… | |

| EN 10217-7, EN10312…… | |

| GB/T12771, HG20537, GB/T24539, GB/T19228, CJ/T151, HG20537.4…… | |

| DIN17457…… | |

| Surface | Pickling |

| Hairline | |

| Polish | |

| End Type | Plain, Bevelled, Threaded, Grooved |

| Joint Method | Fitting, Flange, Welding, Thread |

| Pipe Machining | Welding, Bending, Hole Drilling, Punching, Swaging, Tapering, Flaring, Expanding |

| Procedure | Stainless Steel Seamless Pipe |

| Dimensions | 10.3mm and up 914 |

| 1/8″ and up 36″ | |

| DN6 and up DN900 | |

| Thickness | 1.24mm and 60mm |

| SCH 5S ~SCH XXS | |

| Unit Length | As per standard or customized |

| Standards | GB/T14975,GB/T14976,GB13296,GB5310…… |

| ASTM A312,A213,A269,A376,A511,A959,B677,ISO 15156-3…… | |

| DIN 17456,DIN 17458,EN10216-5…… | |

| JIS G3463,JIS G3459…… | |

| According to required specification is available. | |

| Surface | Pickling |

| Sand Blast | |

| Polish | |

| End Type | Plain, Bevelled, Threaded, Grooved |

| Joint Method | Fitting, Flange, Welding,thread |

| Pipe Machining | Welding, Bending, Hole Drilling, Punching, Swaging, Tapering, Flaring, Expanding |

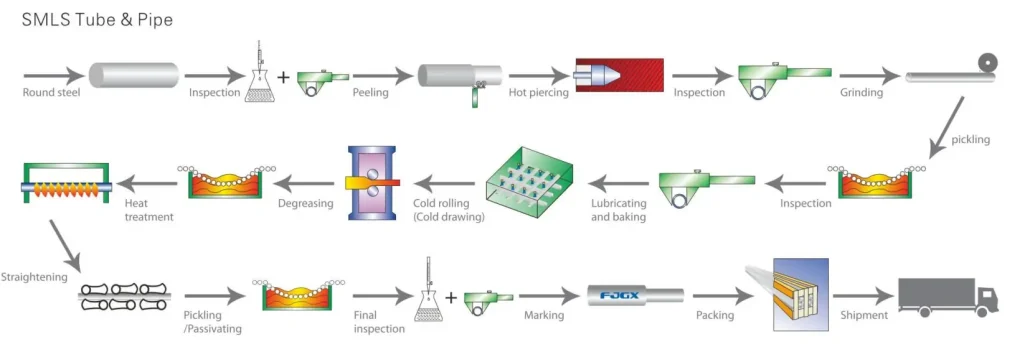

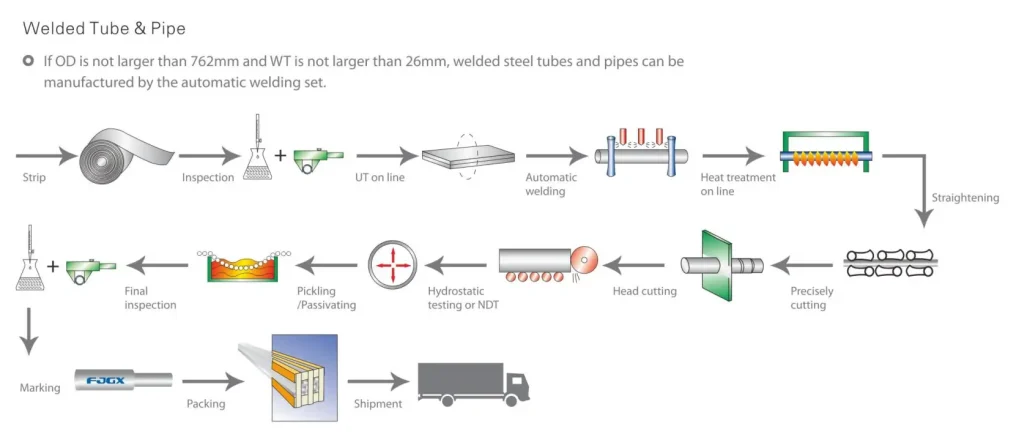

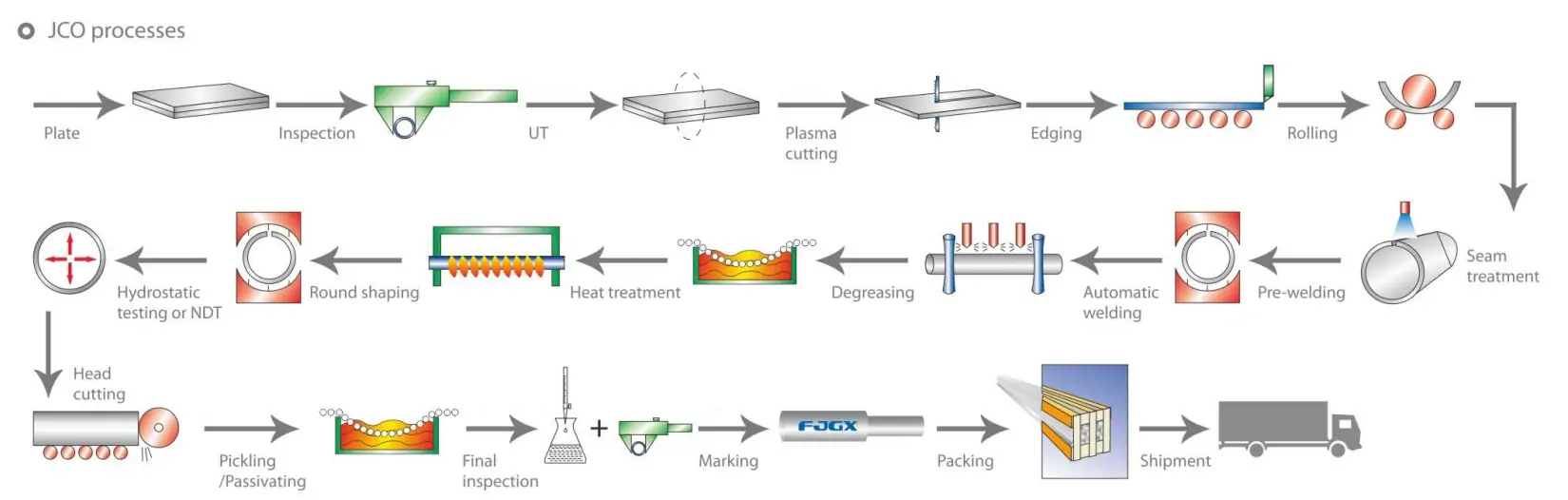

Manufacturing Processing

Applications of Stainless Steel Super Duplex Pipe

About the application of 2507 duplex pipe,among them are ocean and energy engineering, such as high-pressure pipelines for ocean platforms,the bottom of the sea pipelines, and seawater desalination equipment. There are also oil and gas extraction equipment, such as heat ex-changer tubes and down hole tools.

In addition, 2057 pipes are also used in chemical and environmental protection industries, such as corrosion-resistant pressure vessels for chemical reactors, storage tanks, desalination equipment, etc. Common water treatment systems, fire sprinkler systems, etc. Other industrial uses include paper making machinery, food processing equipment, gas purification devices, and other environmental protection equipment.

Types of Packaging

Wooden Boxes

Wooden Pallet

Steel Box

Bundles

(Hexagonal or single tube)

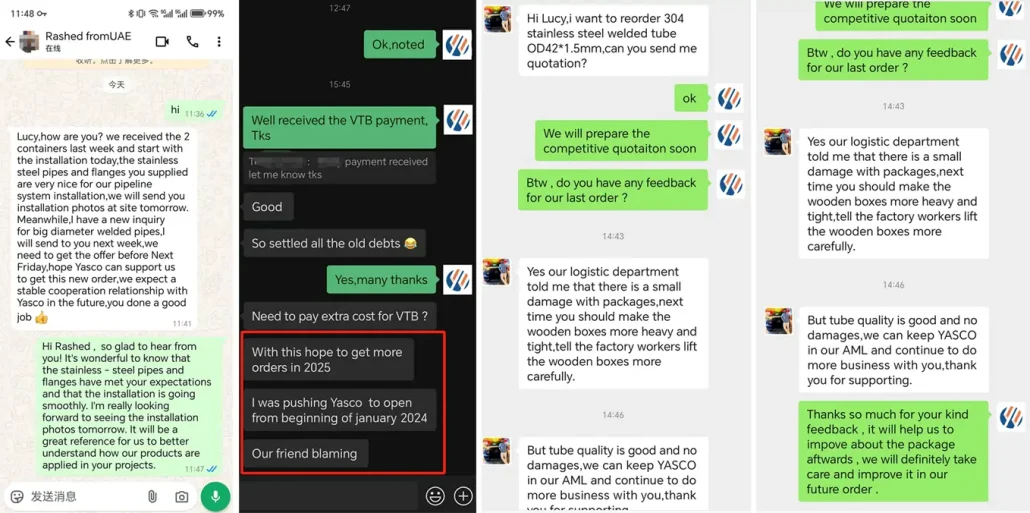

Customer’s Overview

Main Grades:

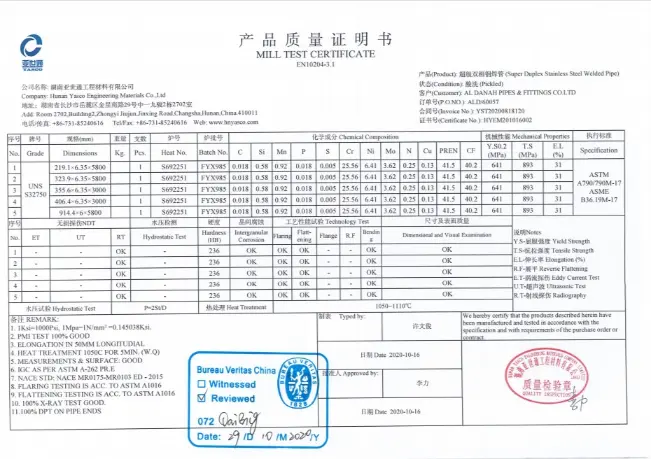

The main grades of super duplex steel vary based on their alloy composition and application environments. Common grades such as UNS S32750 (2507) and UNS S32760 (Zeron 100) are the most widely used in industry. Selecting the appropriate grade depends on the specific application environment, corrosive media, and mechanical performance requirements.

1. UNS S32750

Trade Name: 2507

Features: This is the most widely used grade of super duplex steel, with high chromium, molybdenum, and nitrogen content, offering exceptional corrosion resistance and mechanical properties.

Applications: Oil and gas, seawater treatment, chemical processing equipment.

2. UNS S32760

Trade Name: Zeron 100

Features: The addition of tungsten (W) further enhances corrosion resistance and strength, particularly in high-chloride environments.

Applications: Marine engineering, chemical processing, oil and gas extraction.

3. UNS S32550

Trade Name: 2550

Features: Contains moderate levels of chromium, molybdenum, and nitrogen, making it suitable for moderately corrosive environments while maintaining high strength.

Applications: Chemical processing equipment, pulp and paper industry.