In engineering and manufacturing, precision is of the essence. When it comes to creating structures, systems and products that require durability, corrosion resistance and strength, few materials can match stainless steel. Thin-walled inox tubing is an exceptional product that combines all these qualities and more into a versatile and reliable solution for a wide variety of applications.

We supply a variety of thin wall stainless steel tubes such as 3A stainless steel sanitary tube accommodating the food, beverage, pharmaceutical, or biotechnology industries, our experienced team will assist with any question for you if you purchase thin wall stainless steel tube from us.

Features and advantages

- Lightweight and strong: One of the main features of the excellent thin wall stainless steel tube is its light and strong construction. Compared with the traditional thick-walled stainless steel pipe, the outer diameter of the thin-walled pipe is relatively larger, but the wall thickness is thinner, which makes it greatly reduce its own weight while maintaining its robustness, making it lighter and more flexible.

- Excellent Corrosion Resistance: The thin-walled Stainless Steel Tube is made of high-quality stainless steel material, which has excellent corrosion resistance. They can resist the erosion of corrosive media such as water, acid, alkali, and salt, so they can maintain stable performance even when used in humid or chemically harsh environments.

- Beautiful and Durable: The thin-walled stainless steel tube has a smooth surface and a beautiful appearance with an elegant texture. Its material advantages make it less susceptible to external wear or corrosion, so it has a long service life. At the same time, the stainless steel pipe can also maintain its beautiful appearance without frequent maintenance, saving maintenance costs.

- Hygienic and safe: the stainless steel material is a food-grade material, and the thin-walled stainless steel tube is non-toxic and harmless, and will not react with any harmful substances with food or beverages. Therefore, in food processing, catering and other fields, thin-walled stainless steel pipes are widely used to transport and store food and beverages.

- Environmentally friendly and sustainable: Compared with other materials, stainless steel has a high recycling value and is an environmentally friendly and sustainable material choice. The waste produced in the production process of thin-walled stainless steel pipes can also be recycled and reused, reducing resource waste and environmental burden.

Excellent thin wall stainless steel tube: a comprehensive overview

Excellent thin wall stainless steel tube is an alloy that is widely used in various applications due to its strength, durability, and corrosion resistance. One type of stainless steel that has become more popular in recent years is thin-walled stainless steel tubes.

Material: Excellent thin wall stainless steel tube is made of high-quality stainless steel with a chromium content of not less than 10.5%. The chromium in the alloy reacts with oxygen to form a passivating layer on the surface that prevents corrosion and rust.

Features: The wall thickness is relatively thin, generally 0.5mm to 3mm. The thin-wall design allows for lighter, more flexible tubing, making it easier to bend, form and install. Additionally, the smooth, seamless tube surface provides higher flow rates and lower pressure loss than thicker-walled tubes.

Advantages: The thin-wall design of popular thin wall stainless steel tube has many advantages compared with traditional popular stainless steel seamless pipe made of other materials. First, it is lightweight, making it easier to handle and install. Secondly, it has strong corrosion resistance, which is very suitable for use in harsh environments. Thirdly, the seamless design of the pipe eliminates the risk of leakage and corrosion at the welds, ensuring the pipe works well for a long time. Finally, the high strength and durability of stainless steel means that the tube will not bend or deform easily, even under high pressure.

Properties of thin-walled stainless steel pipe

Excellent thin wall stainless steel tube has several key properties that make it an outstanding material in engineering and manufacturing:

A. Material composition

The main material used in the construction of thin-walled stainless steel tubes is stainless steel. This alloy consists mainly of iron with the addition of chromium and other elements. The exact composition depends on the specific grade of stainless steel chosen, commonly used grades include 304, 316 and 321. Each grade offers unique properties such as enhanced corrosion resistance or improved high temperature performance.

B. Thin wall thickness

One of the distinguishing features of this product is its thin wall thickness. This property makes the excellent thin wall stainless steel tube exceptionally light while maintaining its structural integrity. Thin walls also facilitate efficient heat transfer, making them a valuable choice in applications where thermal conductivity is critical.

C. High strength

Thin-walled stainless steel tubing has exceptional strength and rigidity despite its thin walls. The inherent strength of stainless steel combined with precision manufacturing allows the product to withstand high loads and pressures, making it ideal for applications requiring structural integrity.

D. Corrosion resistance

Stainless steel is known for its excellent corrosion resistance. Thin-walled stainless steel pipes are no exception, with strong rust, oxidation, and chemical resistance. This feature ensures longevity and reliability in environments ranging from marine applications to chemical processing plants.

E. Different sizes and shapes

Thin wall stainless steel tubing is available in a variety of sizes and shapes to suit a variety of applications. Whether you need straight pipe, coiled pipe or a custom configuration, there is a solution for your specific requirements.

F. Precision Tolerances

Thin wall stainless steel tubing is manufactured to tight tolerances for uniform dimensions and exceptional consistency. This precision is critical in applications where tight tolerances are critical for proper fit and function.

The distinctive features of thin-walled stainless steel pipes

Thin wall stainless steel tubing stands out in the market due to a number of unique features:

A. Welded and seamless options

Customers can choose between welded and seamless thin wall stainless steel tubing, each with its own unique benefits. Welded pipe is cost effective and suitable for many applications, while seamless pipe provides increased strength and reliability for critical operations.

B. Polishing

For applications where aesthetics and cleanliness are important, thin wall stainless steel tubing is available with a polished finish. Not only does this enhance its visual appeal, it also simplifies cleaning and maintenance.

C. High temperature resistance

Some grades of thin wall stainless steel tubing, such as 316 and 321, have excellent high temperature resistance. This characteristic makes them indispensable in applications involving extreme heat, such as exhaust systems in the aerospace or automotive industries.

D. Sanitary performance

Stainless steel is known for its hygienic qualities, making thin wall stainless steel tubing ideal for the food and pharmaceutical industries. It is easy to clean, does not react with food or drugs, and maintains its integrity in a sterile environment.

E. Various surface treatments

Thin wall inox tubing is available in a variety of finishes including brushed, satin and mirror finishes. These options meet the varying aesthetic and functional requirements of various industries.

The role of thin-walled stainless steel pipes

Thin wall inox tubing has multiple functions in different industries:

A. Fluid transfer

In industries such as oil and gas, chemical processing, and hydraulics, thin-walled stainless steel tubing is used to move a variety of fluids, including corrosive chemicals and high-pressure hydraulic fluids. Its corrosion resistance and high strength properties ensure the safe and efficient flow of these substances.

B. Heat exchanger

The thin walls and high thermal conductivity of thin-walled stainless steel tubes make them an excellent choice for heat exchangers. Whether cooling systems for electronics or HVAC systems for buildings, this product efficiently transfers heat while maintaining structural integrity.

C. Structural support

The combination of strength and lightweight properties makes thin-walled stainless steel tubing invaluable for structural support in construction, automotive manufacturing, and aerospace applications. It provides the necessary strength without adding unnecessary weight.

D. Automobile exhaust system

The automotive industry relies heavily on thin-wall stainless steel tubing in exhaust systems. Its high temperature and corrosion resistance properties ensure the longevity and performance of these critical components.

E.Medical devices

In the medical field, thin-wall stainless steel tubing is used to make a variety of components, including surgical instruments and medical equipment. Its hygienic properties and durability are critical in these applications.

Advantages of using thin-walled stainless steel pipes

There are many advantages to using thin wall stainless steel tubing in your projects and applications:

A. Longevity and Durability

Thin-wall stainless steel tubing is durable. Its resistance to corrosion, wear and tear ensures a long service life, reducing maintenance and replacement costs.

B. Cost-effectiveness

While the initial cost of stainless steel may be higher than some other materials, its long-term cost benefits become apparent through reduced maintenance and replacement expenses.

C. Versatility

Available in a wide variety of sizes, shapes and grades, thin wall stainless steel tubing is versatile enough to suit different applications across various industries.

D. Reducing environmental impact

Stainless steel is a sustainable material. Its long lifespan and recyclability make it an environmentally friendly choice to contribute to a greener future.

E. Hygienic and easy to clean

In industries where hygiene is critical, the smooth, non-porous surface of thin-walled stainless steel tubing is easy to clean and sanitize to stringent cleanliness standards.

F. Precision Engineering

Exceptional thin wall stainless steel tubes are manufactured to tight tolerances ensuring project consistency and reliability, reducing the risk of errors and operational failures.

Wide range of applications

The excellent thin wall stainless steel tube has the advantages of lightness, corrosion resistance, aesthetics, hygiene and safety, making it widely used in many fields:

- Construction and decoration: Thin-walled Stainless Steel Tube is widely used in the field of construction for indoor and outdoor guardrails, stair handrails, railings and other decorative elements. Its aesthetics, durability and ease of maintenance make it ideal for contemporary architecture and interiors.

- Food processing and beverage industry: Due to the hygienic and safety characteristics of stainless steel, thin-walled stainless steel pipes are often used in pipelines in food processing and catering industries, such as production lines for dairy products, beer, and fruit juices.

- Chemical and Petroleum Industry: Thin-walled stainless steel pipes are used in chemical plants and the petroleum industry to transport chemicals, gases and liquids. Its corrosion resistance enables stable operation in harsh chemical environments.

- Medical Devices: Thin-wall stainless steel tubes are also widely used in the manufacture of medical devices, such as surgical instruments, medical infusion tubes, etc., due to their hygienic performance and excellent strength.

- Aerospace: Due to the lightness of thin-walled stainless steel tubes, it is used in the aerospace field to manufacture aircraft structures, engine piping, etc., which helps reduce aircraft weight and improve fuel efficiency.

In general, the thin-walled Stainless Steel Tube has shown outstanding application value in many fields due to its lightness, firmness, corrosion resistance, aesthetics and safety. It is a trustworthy high-quality pipe in the fields of construction and decoration, food processing, chemical petroleum, and medical aviation.

Mostra de produtos

Thin wall stainless steel tubes have the characteristics of safety and sanitation, high strength, good corrosion resistance, ruggedness, long life, maintenance-free, and aesthetics.

Oficina

The thin wall stainless steel tube is durable and has been recognized by the engineering community, and relevant parties are starting to reduce wall thickness and price to facilitate further promotion.

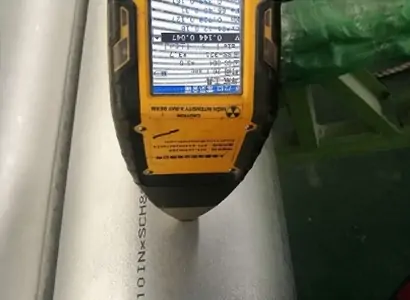

Garantia de qualidade

Our testing of thin wall stainless steel tube is very strict. The testing requirements are all implemented according to standards.

Embalagem e carregamento

The packaging requirements of thin-walled stainless steel tubes are relatively high. Generally, wooden boxes are used for packaging.