We have a large warehouse to stock all the sizes of stainless steel seamless tube, our factory certificated by ISO9001 and also TUV, DNV, ABS, BV, LR qualified, always get warm praise from our customers all over the world, we are your provider of stainless steel seamless tubing.

Excellent stainless steel seamless tube is an essential component in various industrial applications. These tubes are made of high quality stainless steel for excellent corrosion resistance, strength, and durability.

Material

high performance stainless steel seamless tube is made from a combination of iron and chromium. The chromium in the material provides corrosion and stain resistance, making it ideal for use in harsh environments. These tubes can also contain nickel, molybdenum, titanium, and other elements to enhance their performance. The most common types of stainless steel used for seamless tubing are 304 and 316.

Nickel is commonly added to stainless steel tubing to enhance its resistance to both corrosion and high-temperature environments. This addition improves the overall strength and toughness of the tubing, making it highly suitable for applications that require excellent mechanical properties and resistance to extreme conditions.

Molybdenum is another essential element often found in high-performance stainless steel tubing. It offers enhanced resistance to pitting and crevice corrosion, making the tubing highly reliable and durable in corrosive environments such as marine or chemical processing applications.

Titanium, on the other hand, contributes to the tubing’s exceptional strength-to-weight ratio, making it a preferred choice for applications that require lightweight materials without compromising on structural integrity.

The two most commonly used types of stainless steel for seamless tubing are 304 and 316. Type 304 stainless steel is known for its excellent corrosion resistance and is widely used in various industries such as food processing, pharmaceuticals, and architecture. It offers good resistance to most chemicals, as well as atmospheric and fresh water environments.

Type 316 stainless steel, on the other hand, provides superior corrosion resistance compared to 304. It contains higher levels of molybdenum, which enhances its resistance to chloride-induced corrosion. This makes it highly suitable for applications exposed to harsh chemicals, saltwater environments, and marine applications.

characteristic

Has many advantages. Their high strength and durability make them ideal for high pressure applications. They are also resistant to corrosion, stains, and rust, making them ideal for use in harsh environments. In addition, their heat resistance and smooth surface make them ideal for hygienically demanding applications.

Advantage

As a high-quality pipe material, high-performance stainless steel seamless tube has many advantages, making it widely used in various fields. The following is a detailed description of its main advantages:

1. Corrosion resistance: High-performance stainless steel seamless tube has excellent corrosion resistance, which is caused by the passivation film formed by the chromium element in it. The passivation film can prevent water, air and chemicals from coming into direct contact with the inside of the pipe, thus effectively preventing corrosion and rust. This makes stainless steel seamless pipes perform well in harsh environments, can withstand corrosive gases, liquids and wet conditions for a long time, maintain their strength and integrity, and ensure the stable and reliable operation of the pipeline.

2. Pollution resistance: Stainless steel inox tubing has excellent pollution resistance, and its surface is smooth and not easy to adhere to impurities. This makes them ideal for use in applications where piping needs to be kept pure and free from contamination, such as in food processing, pharmaceutical manufacturing and more.

3. High Strength and Durability: Stainless steel seamless pipe has high tensile strength and yield strength, making it an extremely durable material. Capable of withstanding high pressures and loads, they excel in high pressure applications. The seamless manufacturing process also eliminates the negative impact of weld seams on the strength of the pipe, further increasing the durability of the pipe.

4. Heat resistance: Excellent performance in high temperature environment. They can withstand high temperature conditions without warping or fading, making them suitable for use in high temperature applications. This makes stainless steel seamless tubes widely used in petrochemical, energy industries and high temperature processes.

5. High reliability: Due to its excellent corrosion resistance, pollution resistance, high strength and heat resistance, high-performance stainless steel seamless pipes perform well in various fields and are widely recognized by the industry. Its high reliability ensures that the pipeline remains stable and reliable in long-term use, reducing the frequency and cost of maintenance and replacement.

Overall, the corrosion resistance, stain resistance, high strength and heat resistance of high performance stainless steel seamless tube make it ideal for high pressure, high temperature and harsh environments. Its high reliability and durability make it widely used in many industries and applications, such as chemical, petroleum, pharmaceutical, food processing and other fields. High-performance stainless steel seamless pipes provide reliable and efficient pipe solutions for various projects and projects, and meet the high requirements and diverse needs of pipe materials in different industries.

Versatility in high-quality inox tubing

With its excellent performance, stainless steel seamless pipe has multiple functions in different industries:

A. Fluid transfer

In industries such as oil and gas, chemical processing and hydraulics, high-quality inox tubing is used to transfer a variety of fluids, including aggressive chemicals and high-pressure hydraulic fluids. Their corrosion resistance and high strength properties ensure the safe and efficient flow of these substances.

B. Heat exchanger

The seamless construction of these tubes makes them ideal for heat exchangers. Whether it’s a cooling system for electronic equipment or a building’s HVAC system, stainless steel seamless tubing efficiently transfers heat while maintaining structural integrity.

C. Structural support

Stainless steel seamless tubing is integral to structural support in construction, automotive manufacturing, and aerospace applications. They provide necessary strength without adding unnecessary weight.

D. Automobile exhaust system

The automotive industry relies heavily on stainless steel seamless pipes for exhaust systems. Their high temperature and corrosion resistance ensures the longevity and performance of these critical components.

E.Medical devices

In the medical field, stainless steel seamless tubing is used to manufacture a variety of components, including surgical instruments and medical equipment. Their hygienic properties and durability are critical in these applications.

F. Precision parts

These tubing aid in the manufacture of precision components and systems, such as instrumentation tubing, where tight tolerances and reliability are critical.

Reveal the advantages of choosing seamless pipe

Choosing high-quality inox tubing can bring many advantages to your project and application:

A. to increase strength

The seamless construction eliminates welds, making these tubes stronger and more reliable than welded tubes.

B. Durability and longevity

Stainless Steel Seamless Tubing is durable with excellent resistance to corrosion, abrasion and tearing. This longevity reduces maintenance and replacement costs over time.

C. Precision engineering

Manufactured to tight tolerances, these tubes ensure uniform dimensions and excellent consistency, reducing the risk of errors and operational failures in projects.

D. High performance

The absence of welds means that stainless steel seamless tubing is less prone to defects or weaknesses, ensuring high performance in challenging conditions.

E. Versatility and adaptability

Available in a wide variety of sizes, grades and finishes, these tubes are versatile and can accommodate a wide range of applications across industries.

F. Hygienic properties

The non-porous surface of stainless steel seamless pipe coupled with its resistance to corrosion makes it ideal for industries such as food processing and pharmaceuticals where hygiene is critical.

Cross-Industry Applications: Precision Matters

The versatility and unique properties of stainless steel seamless tubing allow it to be used in a wide range of industries:

A. Aerospace

In the aerospace industry where weight and strength are key factors, stainless steel seamless tubing is used in aircraft structures, hydraulic systems, and instrumentation.

B. car

Automakers rely on these tubing for exhaust systems, structural components and fuel lines. Their corrosion resistance ensures the longevity of these critical components.

C. Chemical processing

The resistance of stainless steel seamless tubing to aggressive chemicals makes it indispensable in chemical processing plants for conveying acids, alkalis, and other corrosive substances.

D. Construction

In construction, stainless steel seamless tubing is used for structural supports, building elements and mechanical systems, where its combination of strength and aesthetics is highly valued.

E. Food and drink

The hygienic properties of these tubes make them ideal for food and beverage processing, for transport and storage of products.

F. Healthcare

In the medical field, stainless steel seamless tubing is used for its cleanliness and durability to manufacture surgical instruments, medical devices, and diagnostic equipment.

G. Oil and gas

Stainless steel seamless tubing plays a vital role in the oil and gas industry for conveying corrosive fluids, hydraulic systems and downhole tools.

H. to generate electricity

In power generation facilities, stainless steel seamless tubes are used for heat exchangers, boiler tubes and steam piping due to their high temperature resistance.

I. Traffic

The transportation industry uses stainless steel seamless tubing in the construction of marine components, rail systems and even bicycle frames, where strength and corrosion resistance are critical.

J. Water and Wastewater

Water treatment plants and wastewater treatment facilities rely on these pipes for their corrosion resistance in harsh chemical environments.

K. Marine and offshore

In marine and offshore applications, high quality inox tubing withstands harsh salt water and harsh weather conditions, providing critical support and safety.

Выставка товаров

stainless steel seamless tube made by Yasco Steel is exported to Germany, U.K, France, Netherlands, Belgium, Russia, U.S.A, Korea, Japan, U.A.E, Australia, South Africa, etc.

Мастерская:

Our company has nationally and internationally advanced production equipment, we have complete production equipment, and advanced process technology.

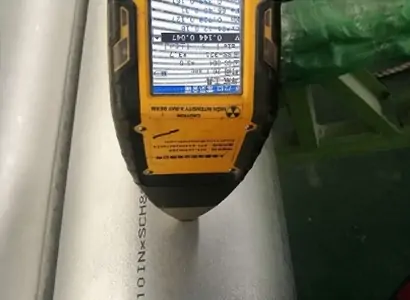

Обеспечение качества:

To ensure product quality, our company is equipped with perfect inspection equipment, hydraulic test, X-ray real time imaging detection system, spectrum analyzer, chemical analyzer, mechanical property tester, etc, to ensure that our company produces high-quality stainless steel seamless tube in strict accordance with GB, HG, ASTM, DIN, JIS, and other standards, Our company has been issued national class A special equipment ISO 9001:2008 quality system.

Применение:

Petroleum and Chemical industry often used acid, alkali, salt, and other corrosive fluids, and stainless steel seamless pipes contain chromium, nickel, and other subgroup metal elements whose characteristics of corrosion resistance and antioxidation can ensure that conveying fluid is not contaminated and pipes will not be eroded by fluid. So stainless steel seamless tube are primarily used for heating piping, heating piping, heat exchanger piping, cooler tube, tower coils pipe, hydrogenation process pipelines, synthesis reactor tube in the synthesis of methanol device and regeneration of catalyst cooler tube in ethylene plants, etc.