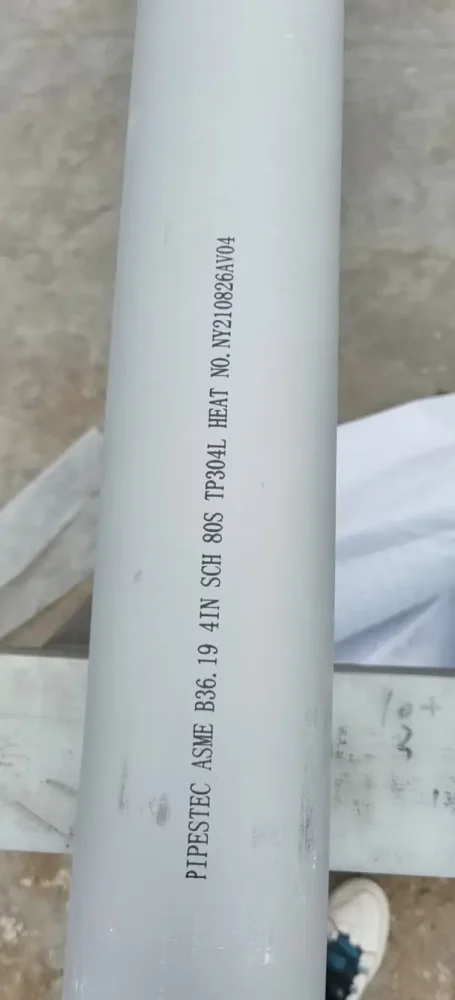

Introduction of 304L Stainless Steel pipe – Low Carbon Corrosion-Resistant Alloy

YASCO 304L stainless steel is a low-carbon variant of the classic 304 austenitic stainless steel, designed to minimize carbide precipitation during welding and enhance corrosion resistance in harsh environments. With its excellent formability, weldability, and durability, 304L is widely used in industries requiring hygienic standards, structural integrity, and long-term performance.

Technical Specifications for Yasco 304L Stainless Steel

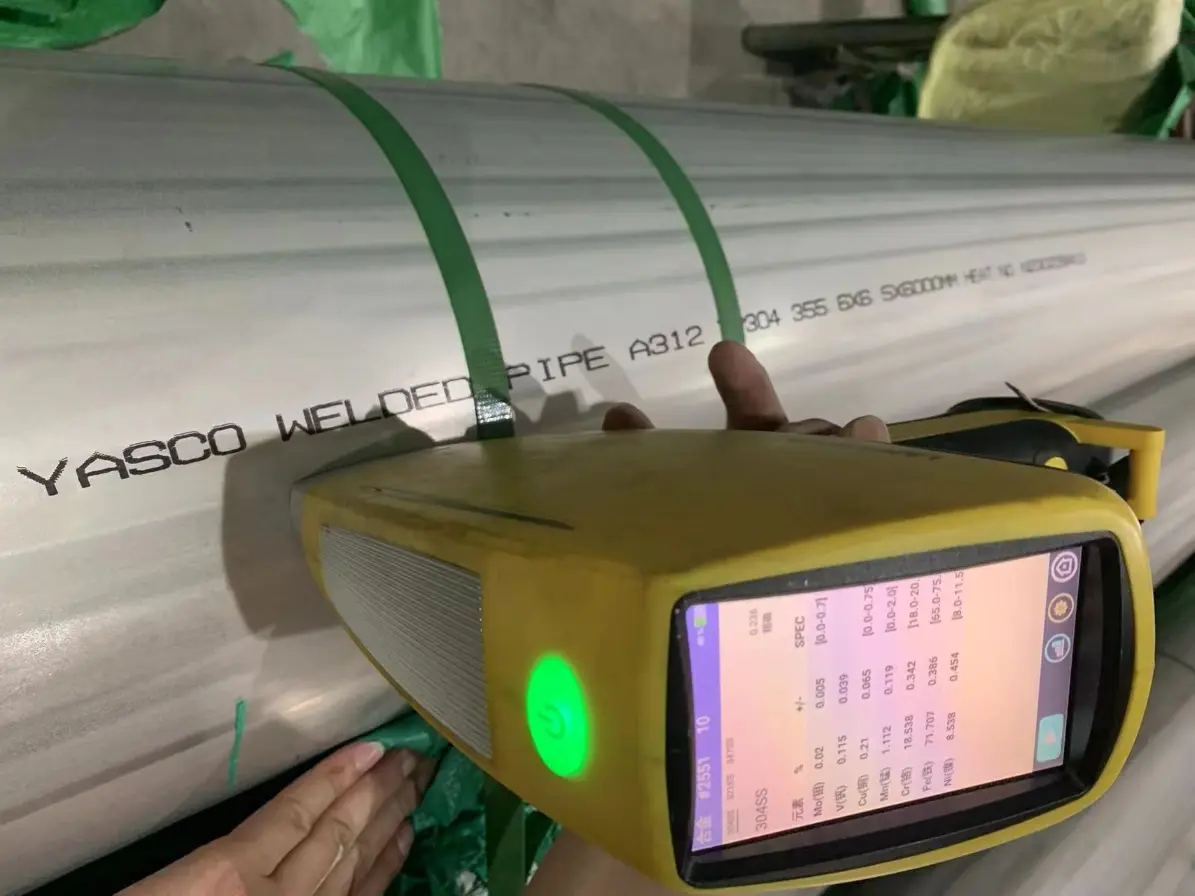

| Property | Component Content |

| Chemical Composition | Cr: 18–20%, Ni: 8–12%, C: ≤0.03%, Mn: ≤2%, Si: ≤1%, P: ≤0.045%, S: ≤0.03%, Fe: Balance |

| Density | 8.0 g/cm³ |

| Tensile Strength | 485 MPa (70 ksi) |

| Yield Strength (0.2%) | 170 MPa (25 ksi) |

| Elongation | 40% (minimum) |

| Melting Point | 1400–1450°C (2552–2642°F) |

| Thermal Conductivity | 16.2 W/m·K (at 100°C) |

| Magnetic Response | Non-magnetic (annealed state) |

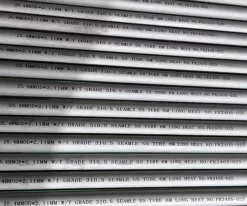

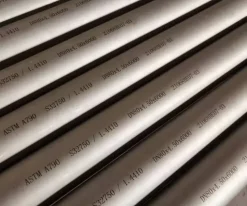

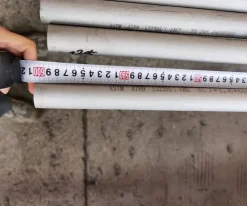

Stainless Steel Pipe Specification Table

Available in seamless and welded forms, with customization options for length, finish, and end preparations.

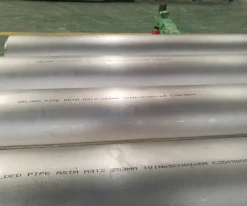

| Procedure | Stainless Steel Welded pipe |

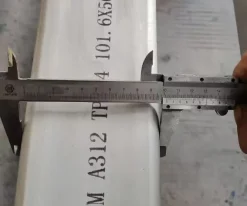

| Dimensions | 10.3mm and up 1372 |

| 1/8″ and up 54″ | |

| DN6 and up DN1350 | |

| Thickness | 1.24mm and 60mm |

| SCH 5S ~SCH XXS | |

| Unit Length | As per standard or customized |

| Standards | ASTM A312, A358, A790, A249,A270…… |

| JIS G3463, G3448, JIS3468…… | |

| EN 10217-7, EN10312…… | |

| GB/T12771, HG20537, GB/T24539, GB/T19228, CJ/T151, HG20537.4…… | |

| DIN17457…… | |

| Surface | Pickling |

| Hairline | |

| Polish | |

| End Type | Plain, Bevelled, Threaded, Grooved |

| Joint Method | Fitting, Flange, Welding, Thread |

| Pipe Machining | Welding, Bending, Hole Drilling, Punching, Swaging, Tapering, Flaring, Expanding |

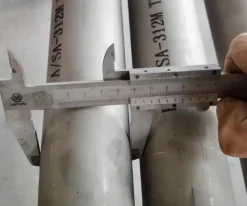

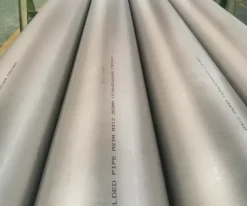

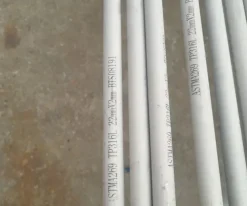

| Procedure | Stainless Steel Seamless Pipe |

| Dimensions | 10.3mm and up 914 |

| 1/8″ and up 36″ | |

| DN6 and up DN900 | |

| Thickness | 1.24mm and 60mm |

| SCH 5S ~SCH XXS | |

| Unit Length | As per standard or customized |

| Standards | GB/T14975,GB/T14976,GB13296,GB5310…… |

| ASTM A312,A213,A269,A376,A511,A959,B677,ISO 15156-3…… | |

| DIN 17456,DIN 17458,EN10216-5…… | |

| JIS G3463,JIS G3459…… | |

| According to required specification is available. | |

| Surface | Pickling |

| Sand Blast | |

| Polish | |

| End Type | Plain, Bevelled, Threaded, Grooved |

| Joint Method | Fitting, Flange, Welding,thread |

| Pipe Machining | Welding, Bending, Hole Drilling, Punching, Swaging, Tapering, Flaring, Expanding |

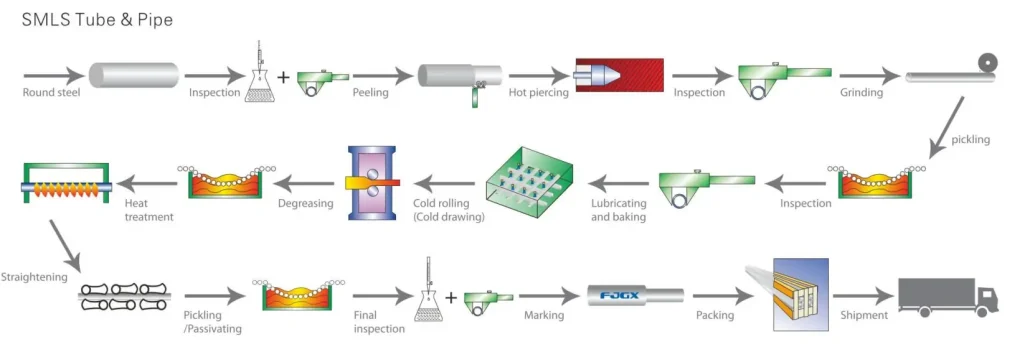

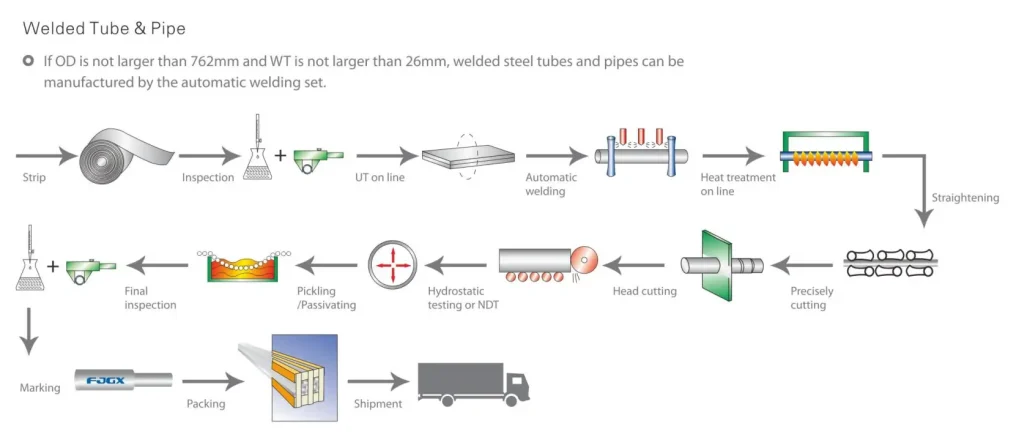

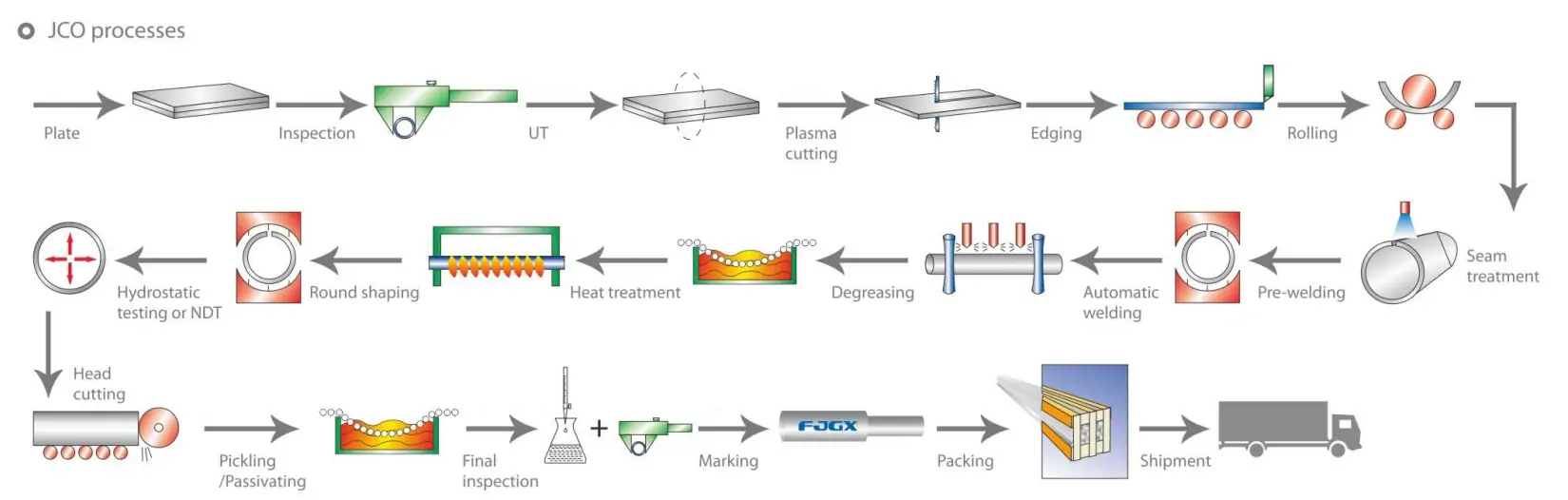

Manufacturing Processing

- Seamless 304L stainless steel pipe: manufactured through hot rolling, cold rolling, or cold drawing processes, suitable for high-pressure, high-precision scenarios.

- Welded 304L stainless steel pipe : using straight seam or spiral welding technology, mostly used for decoration and low-pressure pipeline systems.

Applications of 304L Stainless Steel Pipe

| Scenario | Recommended Grade | Reason |

| Food Processing Equipment | 304L | Low carbon meets hygienic standards; no post-weld treatment required. |

| Architectural Decor (Non-Welded) | 304 | Lower cost and slightly higher strength. |

| Chemical Piping (Welded) | 304L | Avoids corrosion risks in welded zones. |

| High-Temperature Non-Welded Parts | 304 | Slightly higher carbon enhances high-temperature strength. |

Types of Packaging

Wooden Boxes

Wooden Pallet

Steel Box

Bundles

(Hexagonal or single tube)

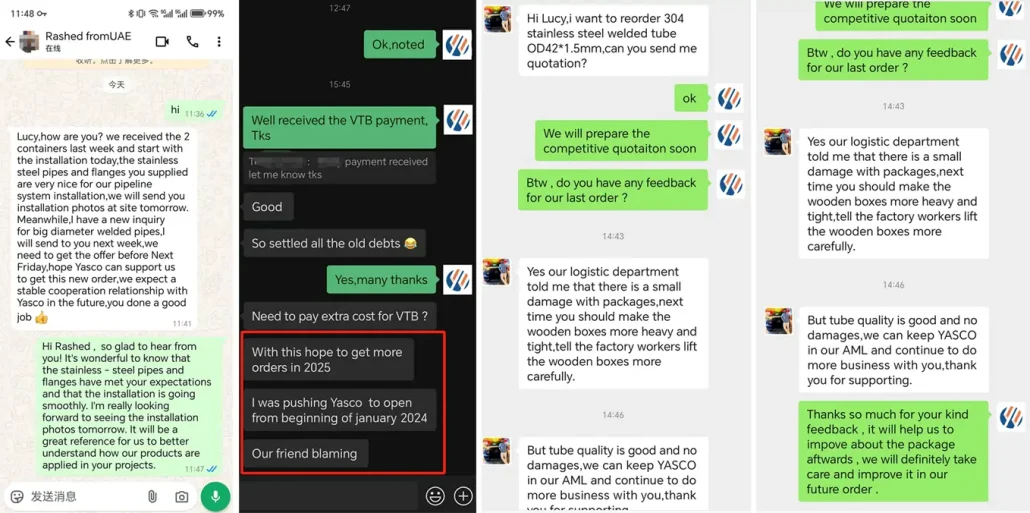

Customer’s Overview

How to Choose 304/304L SS Pipe?

304 Stainless Steel

For non-welded or minimally welded applications requiring higher strength (e.g., structural components, bolts, room-temperature equipment).

304L Stainless Steel

Long-lasting and noise-reducing, this imported fully enclosed compressor is an original product.